Wild Hornets’ 3D Printed Drone interceptors cost 1,000x less than Patriot Missiles, helping Ukraine strengthen air defense amid rising threats.

The ongoing Russia-Ukraine war has significantly increased the demand for 3D Printed Drones on the battlefield. Ukrainian drone manufacturer Wild Hornets has designed a cost-effective 3D printed interceptor drone to replace the U.S.-supplied Patriot missiles. While each Patriot missile costs around $3.3 million, the production cost of a 3D printed interceptor is only $1,000 to $5,000, meaning one missile could be replaced by nearly 1,000 drones.

On the eastern front, both sides have deployed low-cost, remotely controlled First-Person View (FPV) drones to conduct precision strikes, aerial reconnaissance, and supply missions. Reports indicate that Russia produced more than 6,000 Shahed drones last year. By June 2025, over 5,000 Shaheds had already been used against Ukraine. On July 8, Russia launched a record-breaking 700 drones in a single day, marking the highest daily attack volume to date.

In response, Ukraine is rapidly accelerating its production of interceptor drones. Operators use these drones to detect and destroy Shahed loitering munitions before they strike. In a recent interview with Babylon, Arsen Zhumadilov, head of Ukraine’s Defense Procurement Agency, revealed that Kyiv is working toward “mass production”, with contracts signed for tens of thousands of counter-Shahed drones.

Additive manufacturing plays a key role in meeting this growing demand. Ukrainian drone maker Wild Hornets operates an expanding 3D printing factory, dedicated to producing its flagship model—the “Sting” interceptor drone. This approach provides Ukraine with a scalable, low-cost, and rapidly deployable solution for strengthening its air defense system.

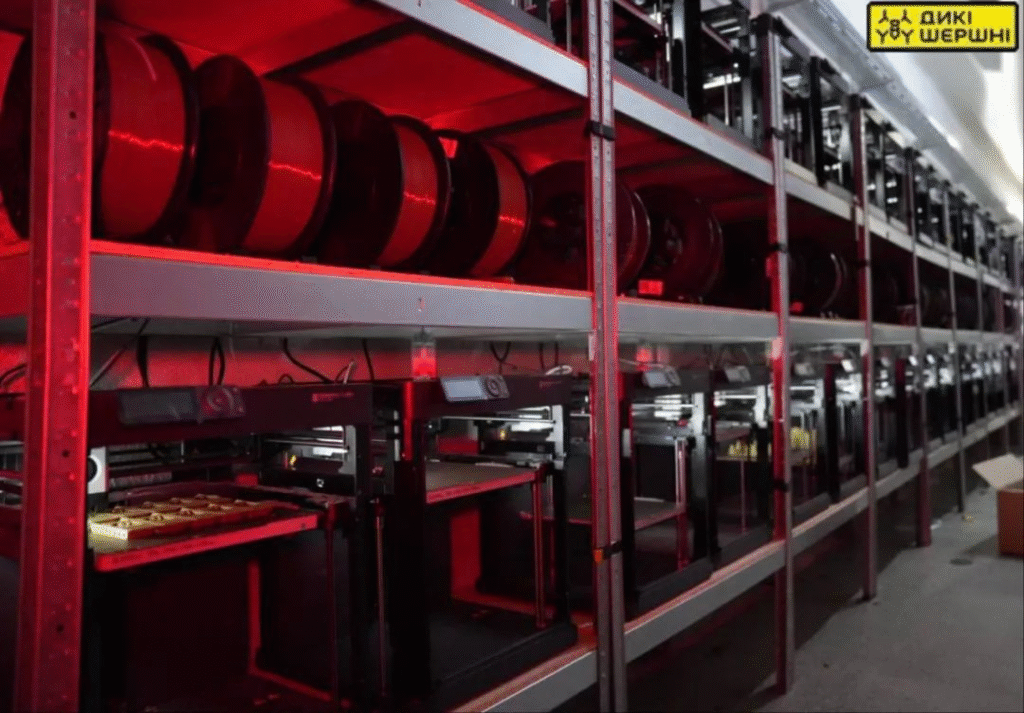

This Ukrainian nonprofit organization has shared images and videos on social media showing rows of Elegoo and Bambu Lab FDM 3D printers producing plastic drone components. These efforts help reduce costs, accelerate design cycles, and enable decentralized production.

Importantly, Wild Hornets provides a cost-effective alternative to the U.S.-supplied Patriot missiles, each of which costs around $3.3 million. By contrast, Ukraine’s 3D printed interceptor drones are reported to cost between $1,000 and $5,000 per unit, while Russia’s Shahed drones are estimated at $35,000 each.

Kyiv, Ukraine — The ongoing Russia-Ukraine war is fueling rapid innovation in drone technology, with 3D printing playing a pivotal role. One standout is Wild Hornets, a volunteer-led organization funded through donations and crowdfunding, which has quickly become one of Ukraine’s key domestic drone suppliers since its founding in spring 2023.

The group currently produces around 100 drones per day, including lightweight 10-inch FPV quadcopters for ground combat, the heavy “Queen Hornet” bomber, and the high-speed “Sting” air-defense interceptor drone.

The Sting: A New Generation of Interceptors

The Sting features a distinctive bullet-shaped quadcopter design optimized for aerodynamics. It can reportedly reach 160 km/h (100 mph) at altitudes up to 3,000 meters (10,000 feet). Development began in October 2024, and the drone is armed with a warhead and thermal imaging system. Operators, wearing VR headsets, employ dogfight-style tactics to intercept and destroy incoming Shahed drones.

Earlier this month, Ukrainian President Volodymyr Zelensky praised Wild Hornets in a Facebook post, noting that interceptor drones had “performed especially well, shooting down hundreds of Russian-Iranian Shahed drones over the past week.” According to the organization, its drones have already destroyed 1,738 enemy assets valued at $1.69 billion, including 448 enemy drones.

3D Printing as a Strategic Advantage

Wild Hornets sources 65% of its drone components locally. The organization is also expanding its fleet of FDM 3D printers, enabling rapid production scaling and fast design iteration to adapt to battlefield demands.

A July 2 post on X showed shelves stacked with Bambu Lab 3D printers and rows of drone parts, with the caption: “Our drone production never stops—only work, because every drone matters.” A June video revealed close-up footage of the 3D printing process, offering a rare look into the group’s nonstop operations.

From a secret facility in western Ukraine, more than 100 staff members now produce about 1,000 drones per day using advanced manufacturing technologies. While the Sting interceptors are a highlight, most production remains focused on lightweight suicide drones for frontline strikes.

Global Expansion of 3D Printed Drone Warfare

Ukraine is not alone in adopting 3D printing for drone production. German startup Tytan Technologies supplies AI-controlled drones developed through additive manufacturing. Its Tytan Interceptor, designed to counter the Shahed-136 (Geran-2), features a 3D-printed airframe capable of 250+ km/h, carrying up to 1 kg of payload with an operational range of over 15 km.

In the United States, Firestorm Labs recently raised $47 million in Series A funding, led by NEA with participation from Lockheed Martin Ventures and other defense investors. The funds will expand Firestorm’s 3D printed drone systems and its deployable micro-factory, xCell, which allows modular drone airframes to be 3D printed directly in the field.

The U.S. Air Force has already awarded Firestorm a five-year, $100 million IDIQ contract to advance modular, cost-effective 3D printed drone solutions.

Additionally, Alabama-based Cummins Aerospace completed the first test flight of its 3D printed loitering munition “Hellhound S3.” Powered by a turbojet engine, the S3 can reach 384 mph, providing long-range precision strike capability against armored vehicles, tanks, and fortified positions.