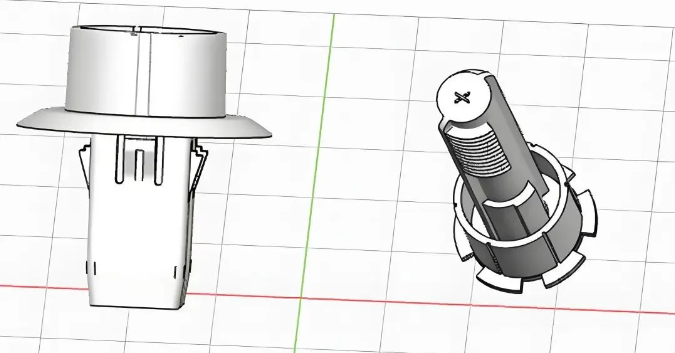

3D Printing Transforms Automotive Prototyping: From Clips to Cooling Valves

3D printing is increasingly being used to produce clips, pipe clamps, and other fastening components, as well as functional critical parts such as valves for engine cooling systems. In the past, the production of prototypes and parts often relied heavily on outsourced machining—a traditional approach that has revealed multiple shortcomings:

Long lead times: Receiving samples typically required 1–2 weeks after ordering, significantly delaying design validation and trial assembly.

High costs: The expense of one-off mold making and machining was prohibitively high, making multi-round iteration impractical.

Uncertain delivery: Dependence on external resources meant that urgent changes or expedited requests could not always be accommodated.

Low verification efficiency: When design modifications were made, the turnaround for updated prototype parts was slow, hindering development progress.

SLA Workstation

To meet the demands of rapid iteration and precision trial assembly for automotive components, the DF2+ photopolymerization 3D printer was selected as the printing solution, based on a comprehensive evaluation of printing efficiency, dimensional accuracy, and material compatibility.

The DF2+ achieves a printing speed of up to 100 mm/h, making it particularly well-suited for rapid prototyping and small-batch production. Combined with the ideaMaker® slicing software and an RFID-based smart recognition system, the printer automatically configures parameters across the DF Wash cleaning station and DF Cure curing station. This enables a fully integrated, closed-loop workflow from printing to curing, ensuring stable and consistent output quality throughout batch production.

Materials used

Tough 2K Gray V1 Resin: Featuring excellent toughness and impact resistance, this resin is ideal for printing structural components such as wire harness fasteners, clips, and pipe clamps that require high impact strength.

Rigid 3K Gray V1 Resin: Combining high rigidity with superior strength, this material is well-suited for housings, structural parts, and other applications where dimensional stability and stiffness are critical.

General Purpose White V1 Resin: A versatile resin designed for rapid prototyping and structural evaluations, enabling efficient design verification.

Elastic Black 65° Resin: Tailored for lightweight, flexible connector components, this resin has been validated through extensive testing to deliver stable and reliable performance.

Application Scenarios: Tooling, Design Validation, and On-Vehicle Trial Assembly

Tooling Production: Custom clips, pipe clamps, and assembly jigs can be additively manufactured. Compared with traditional machining, up to four sets of parts can be printed in a single run with an accuracy of 0.05 mm and delivered within just 3.5 hours.

Design Validation: During prototype vehicle development, structural components such as clips and brackets can be 3D printed to verify installation fit and structural compatibility under real-world usage conditions.

On-Vehicle Trial Assembly: After surface finishing and painting, printed parts can be directly installed on vehicles. This enables full-process testing of functional components such as caps, valves, and fluid containers, significantly reducing the risk of trial assembly failures.

Results & Value: Breakthroughs in Cost, Time, and Innovation

The introduction of the Raise3D DF2+ DLP printing workstation has significantly optimized product validation processes and overall cost control.

Cost Savings: Initial prototyping costs were reduced by approximately 33%, with marginal costs per unit continuing to decrease as usage scales up.

Accelerated Lead Times: Verification parts can now be delivered 3–5 days faster, enabling multiple projects to progress in parallel.

Performance Enhancement: By leveraging design freedom and material customization, overall component performance has improved by around 15%.

Autonomous Control: Daily on-demand production of 2–3 parts ensures flexible manufacturing pace and rapid response to design changes.

High Resolution: DLP technology delivers assembly-grade precision, minimizing post-processing adjustments and reducing tuning time.

As the automotive industry increasingly pursues personalization, lightweighting, and rapid iteration, 3D printing is steadily becoming a core enabler of flexible manufacturing ecosystems.