Using advanced 3D printing techniques, researchers have successfully fabricated high-performance aluminum–silicon carbide (Al/SiC) metal matrix composites. These materials combine the toughness of aluminum alloys with the high hardness, thermal conductivity, low thermal expansion, and superior wear resistance of SiC. They are well-suited for satellite structural components, laser communication gimbals, and UAV fuselages, enabling lightweight designs (≥30% weight reduction) while ensuring stability and reliability in extreme environments. This achievement holds significant potential for aerospace, electronic packaging, and new energy vehicle applications.

Industry Pain Points

Although aluminum–silicon carbide (Al/SiC) composites combine lightweight, high thermal conductivity, low expansion, and excellent wear resistance, the high hardness of SiC makes machining difficult, time-consuming, and costly, limiting mass adoption. Current metal laser cladding AM processes can only produce low-volume fraction (≤15%) Al/SiC, falling short of high-performance application requirements.

Innovative Solution: Photopolymerization 3D Printing + Aluminum Infiltration

To address the above challenges, high-performance Al/SiC composite materials were successfully fabricated using ceramic photopolymerization additive manufacturing equipment. The technical process is as follows:

Slurry Preparation – Mix SiC powder with photosensitive resin and dispersants to obtain a low-viscosity, high-solid-loading, highly reactive SiC-resin slurry.

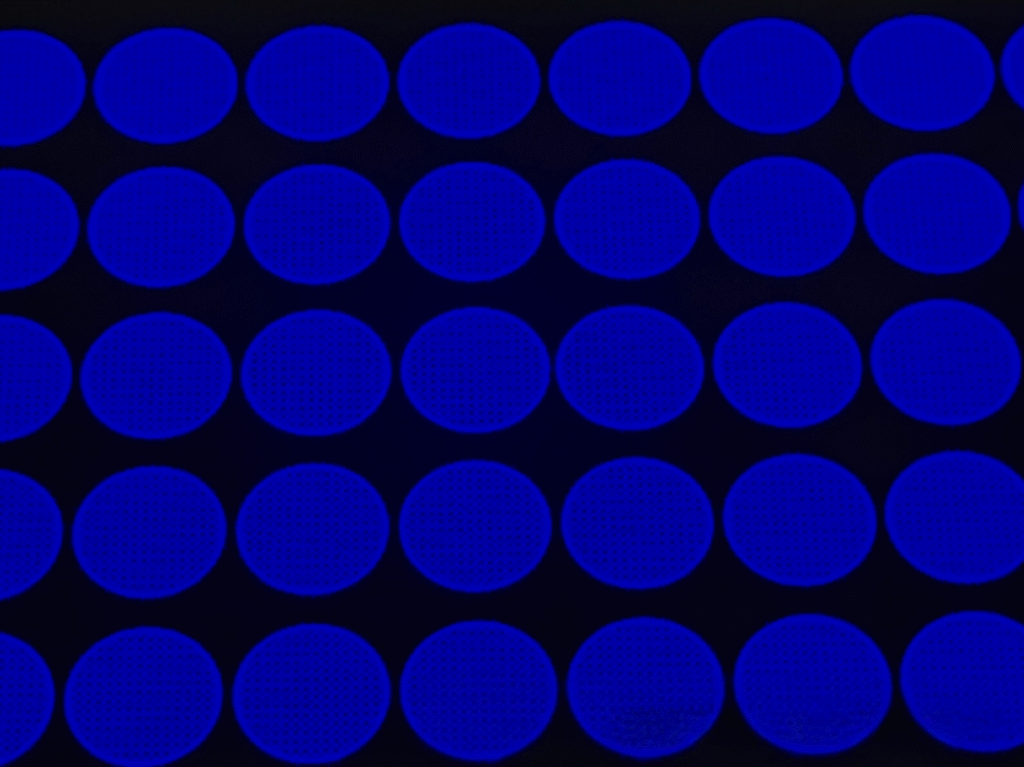

Photopolymerization Printing – Load the slurry into a DLP ceramic 3D printer and solidify layer by layer with UV light to form a SiC green body.

Debinding & Sintering – Heat-treat the green body to remove organics and release residual stresses, yielding a porous SiC skeleton.

Aluminum Infiltration – Perform molten aluminum infiltration to fully fill the pores, resulting in a dense, uniform Al/SiC composite sample.

This approach significantly increases SiC volume fraction and material density, achieving performance closer to industrial requirements and opening new possibilities for satellite structures, UAV fuselages, and precision thermal management components.

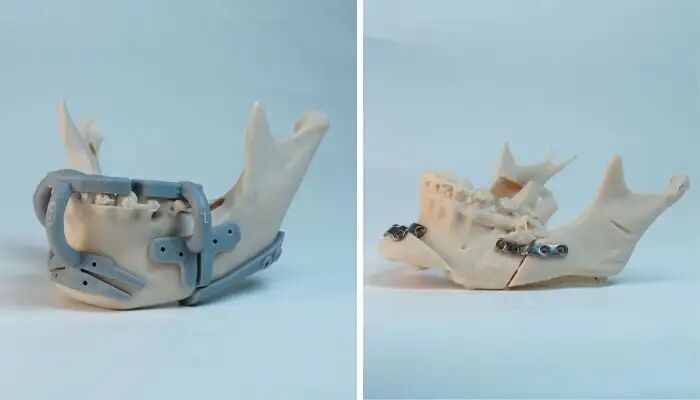

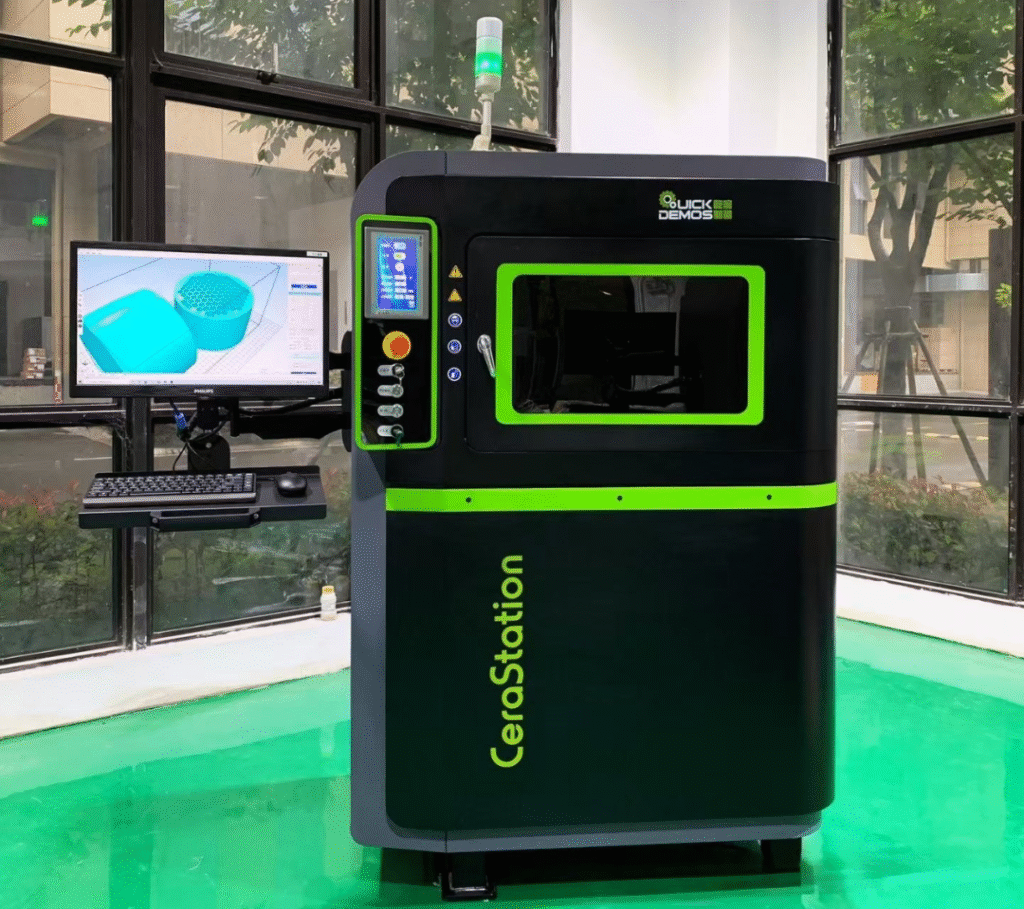

3D Printing Equipment and Silicon Carbide Ceramic Green Body Printing

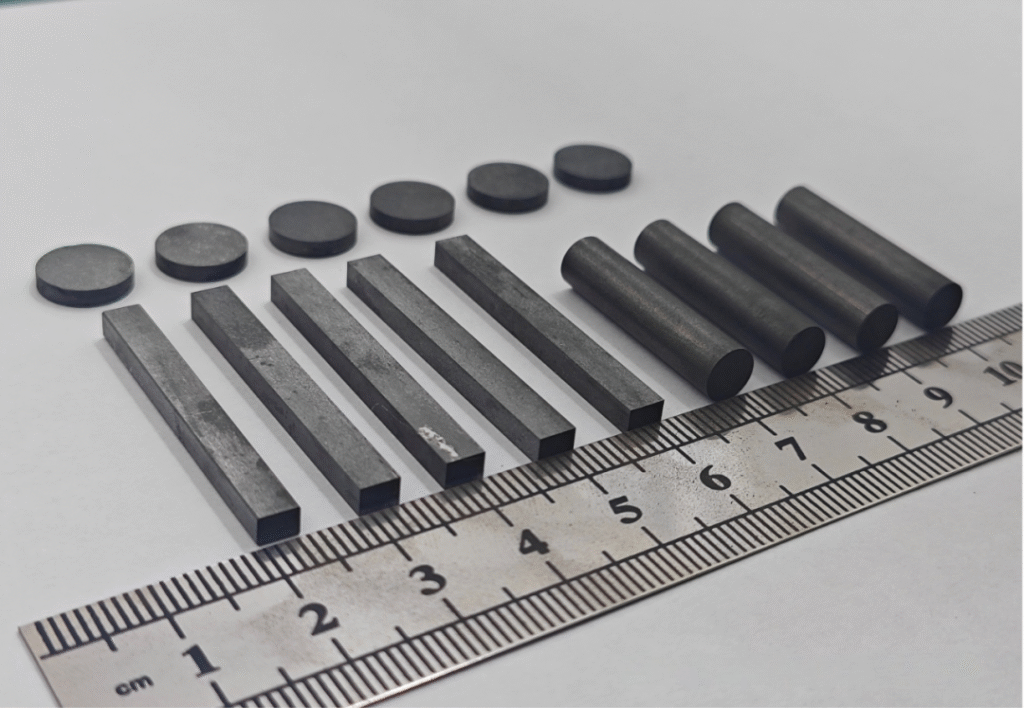

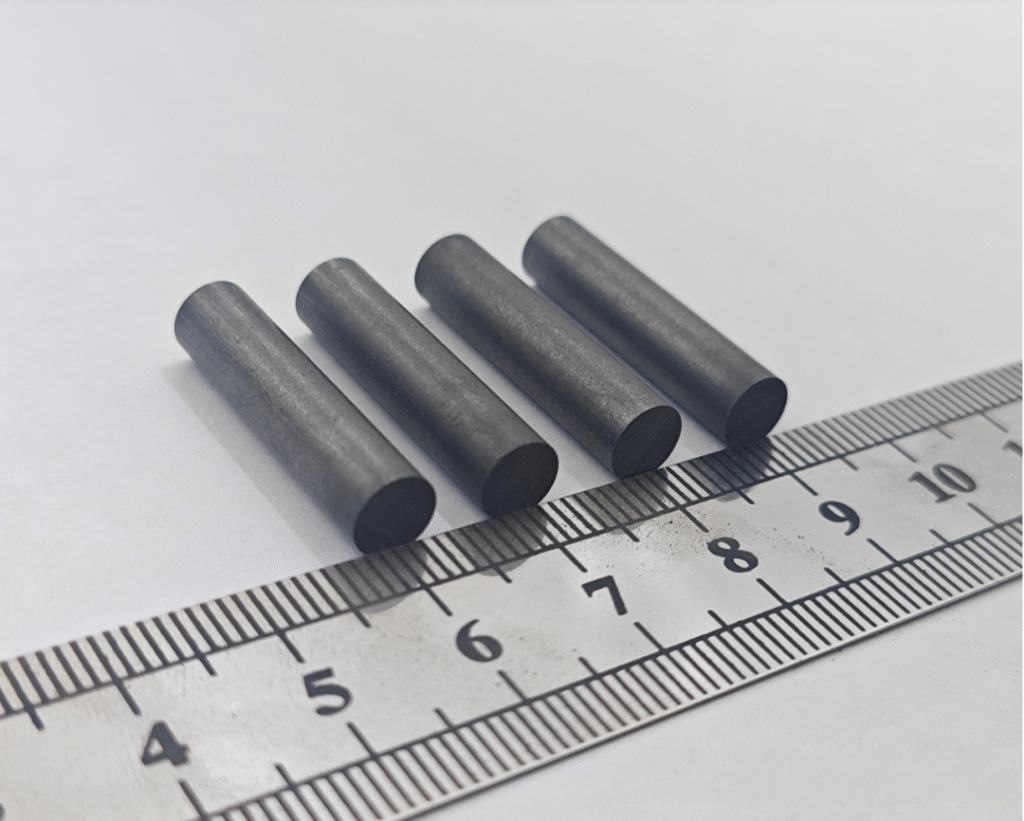

Aluminum Matrix Silicon Carbide (Al/SiC) Sample

Properties of Aluminum Matrix Silicon Carbide (Al/SiC) Composites

| Material Properties | Density (g/cm³) | Porosity (%) | Bending Strength (MPa) | Elastic Modulus (GPa) | Thermal Conductivity (RT, W·m⁻¹·K⁻¹) | Thermal Expansion Coefficient (30°C, ×10⁻⁶ K⁻¹) |

| Al/SiC | 3.01 | 0.31 | 512.47 | 124.65 | 170 | 8.05 |

Technical Advantages and Application Prospects of the Solution

The “Photopolymer 3D Printing – Debinding Pre-treatment – Aluminum Infiltration” process for manufacturing aluminum matrix silicon carbide (Al/SiC) components centers on two critical factors: the solid loading of the SiC slurry and the mechanical strength of the porous SiC structure after debinding. These are precisely where QianDu High-Tech’s ceramic additive manufacturing equipment excels.

Compared with conventional Al/SiC manufacturing processes, this innovative route offers shorter production cycles, superior performance, and lower costs. Moreover, it breaks through the design limitations of traditional manufacturing methods, significantly increasing the design freedom of Al/SiC components. The aluminum infiltration process further enhances the material’s density and strength, improving structural uniformity and overall reliability.

QianDu High-Tech’s Al/SiC technology is poised to enable breakthroughs in multiple sectors:

Aerospace Applications

Customized opto-mechanical structures for space optics, providing high-precision solutions for critical optical components.

Electronics Packaging

Bases for radar microwave power tubes, IGBT substrates, and other packaging components — achieving over 80% weight reduction compared with conventional tungsten/copper (W/Cu) alloys.

Thermal Management

With the rapid adoption of 800V high-voltage fast-charging SiC platforms in electric vehicle manufacturing, SiC device penetration in premium EVs has surpassed 30%, driving sustained demand for high-performance Al/SiC materials.