With the rapid development of 3D printing technology, its potential in the field of defense manufacturing is being continuously explored.

In the military industry, increasing attention is being paid to whether 3D printing could bring revolutionary changes to tungsten alloy armor-piercing rounds. From a technical perspective, additive manufacturing offers the ability to optimize the internal structure of penetrator cores, enhance armor-piercing performance, reduce overall weight, and improve customization capabilities.

However, challenges remain. Issues such as process maturity, material costs, and the need for large-scale reliability verification still pose obstacles to widespread application. Even so, experts believe that as these barriers are gradually overcome, 3D printing could reshape the future of next-generation ammunition manufacturing.

On July 7, 2025, during the first half of the MILAM 2025 exhibition, U.S.-based materials and manufacturing technology developers HAMR Industrie and Freemelt jointly showcased their latest achievements in tungsten additive manufacturing.

One of the highlights was the successful production of high-precision tungsten alloy armor-piercing rounds, manufactured directly using the Freemelt One electron beam powder bed fusion (EB-PBF) system.

International Advances: U.S. Companies Push Boundaries of Tungsten Alloy Ammunition with Electron Beam 3D Printing

Pittsburgh, USA — July 7, 2025 — At the MILAM 2025 exhibition earlier this year, U.S. materials and manufacturing technology developers HAMR Industrie and Freemelt unveiled a major breakthrough in tungsten additive manufacturing. A key highlight was the successful production of high-precision tungsten alloy armor-piercing rounds, manufactured directly using the Freemelt One electron beam powder bed fusion (EB-PBF) system at the Neighborhood 91 additive manufacturing hub.

Armor-piercing rounds remain one of the primary munitions designed to defeat tanks and armored combat vehicles, relying on tremendous kinetic energy to penetrate heavy defenses. Tungsten, with its exceptionally high melting point, density, and hardness at elevated temperatures, is considered one of the ideal materials for penetrator cores. As a result, tungsten alloy rounds—typically composed of pure tungsten or tungsten-based composites—are widely adopted for their superior density and outstanding armor-piercing capabilities.

Yet these same material advantages present formidable challenges for traditional manufacturing. Tungsten’s brittleness and ultra-high melting point make machining and processing extremely difficult, while rapid temperature fluctuations can easily cause brittle fractures, driving up production costs and limiting scalability.

The introduction of 3D printing, particularly EB-PBF, offers a new solution. Operating in a vacuum environment with a high-energy electron beam as the heat source, EB-PBF enables layer-by-layer melting of metal powders at temperatures exceeding 1,000°C. Compared to conventional laser beam powder bed fusion (LB-PBF), this process significantly reduces the risk of cracking and allows for the production of dense, defect-free tungsten components.

By continuously refining the eMelt system and Pixelmelt point-melting software, HAMR Industrie and Freemelt have further advanced the efficiency and quality of tungsten alloy penetrator manufacturing. Industry experts believe that these achievements not only mark a milestone in defense-related additive manufacturing but also underscore the disruptive potential of 3D printing in high-performance materials engineering worldwide.

Freemelt One EB-PBF Additive Manufacturing System

EB-PBF Innovation and Tungsten Additive Manufacturing Optimization

As one of the core materials in Freemelt’s product portfolio—alongside titanium and copper—tungsten has become central to the company’s research and development strategy. Leveraging its electron beam powder bed fusion (EB-PBF) technology, Freemelt has achieved the ability to process high-density, crack-free pure tungsten microstructures. Unlike the earlier linear melting strategies, the company is now pioneering a point-melting approach enabled by its proprietary Pixelmelt software, which improves beam power utilization and overall production efficiency.

Further enhancing this capability, Freemelt has developed a proprietary electron beam source featuring a diode structure with a laser-heated cathode. This design maintains stable beam spot quality across the 0–6 kW power range, overcoming the long-standing challenge of spot degradation at higher power levels faced by traditional systems.

Performance Gains in Tungsten Alloy Armor-Piercing Rounds

When applied to the production of tungsten alloy armor-piercing rounds, this advanced 3D printing technology has delivered measurable performance improvements. The 3D-printed rounds are approximately 15% lighter than their conventionally manufactured counterparts, thanks to optimized mass distribution within the penetrator core that also reduces aerodynamic drag.

Test results are striking: at an initial velocity of 2,000 meters per second, these 3D-printed tungsten alloy rounds demonstrated a 15% increase in penetration depth against homogeneous steel armor. Additionally, the integrity of the recovered penetrator fragments improved by nearly 30%, underscoring both the enhanced durability and efficiency of the additive manufacturing approach.

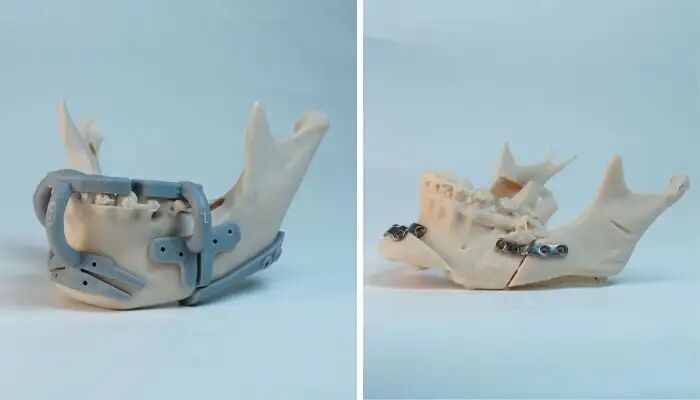

Tungsten Alloy Armor-Piercing Rounds Produced via Electron Beam Powder Bed Fusion (EB-PBF) 3D Printing

Superior Armor-Piercing Performance with Additive Manufacturing

On modern battlefields, main battle tanks are increasingly equipped with composite armor, reactive armor, and active protection systems, creating formidable challenges for penetrator rounds. In high-velocity impact scenarios, armor-piercing rounds must concentrate their kinetic energy within milliseconds, break through multiple layers of defense, and maintain structural integrity. In such conditions, the performance advantages of 3D-printed tungsten alloy rounds become particularly evident.

Enhanced Lethality:

With a density nearly three times higher than steel, tungsten alloy penetrators of the same volume carry greater mass and kinetic energy. The introduction of 3D printing further amplifies these advantages: by refining the internal architecture of the penetrator core, hardness is increased by approximately 30%, alongside superior fracture resistance. This ensures that under high-velocity impacts, the projectile tip remains stable and effective in penetrating multilayer armor. Field tests confirm that under identical firing conditions, 3D-printed tungsten alloy rounds maintain about 10% higher residual velocity than conventionally manufactured rounds after penetrating 650 mm of homogeneous steel armor at a range of 2,000 meters. Moreover, their post-penetration fragmentation patterns are more concentrated, producing significantly stronger secondary damage effects.

Resistance to Heat and Deformation:

During extreme high-velocity impacts, the tip temperature of an armor-piercing round can soar to several thousand degrees—enough to melt most metals. Testing shows that 3D-printed tungsten alloy penetrators exhibit a deformation depth of less than 1 mm under such conditions, compared with 3–5 mm for traditional tungsten alloy rounds. This reduced deformation ensures greater penetration stability, enabling the 3D-printed rounds to reliably punch through three layers of spaced armor, meeting the tactical requirements of complex battlefield environments.

Stronger Penetration of Composite Armor:

Modern composite armors often feature a “soft–hard–soft” layered structure, which can trap conventional tungsten alloy penetrators in the intermediate layers. By contrast, 3D-printed tungsten alloy penetrators benefit from a unique “self-sharpening” tip effect: upon impact, the round sheds dulled edges and maintains a sharp profile, avoiding entrapment within the soft layers of composite armor. Additionally, internal cavity structures—made possible only through additive manufacturing—help dissipate shock waves, preventing excessive stress concentration and reducing the risk of projectile fracture. This design not only enhances penetration capability against composite armor but also lowers the likelihood of ricochets.

Toward Deployment on the Battlefield

Overall, as 3D printing technology continues to advance alongside new materials and process innovations, tungsten alloy 3D-printed armor-piercing rounds are expected to transition from the laboratory to actual combat in the near future, becoming a powerful weapon for breaching advanced enemy armor systems. Beyond munitions, additive manufacturing is anticipated to see broader applications in aerospace, military logistics, and intelligent defense equipment production, accelerating the modernization and adaptability of future armed forces.