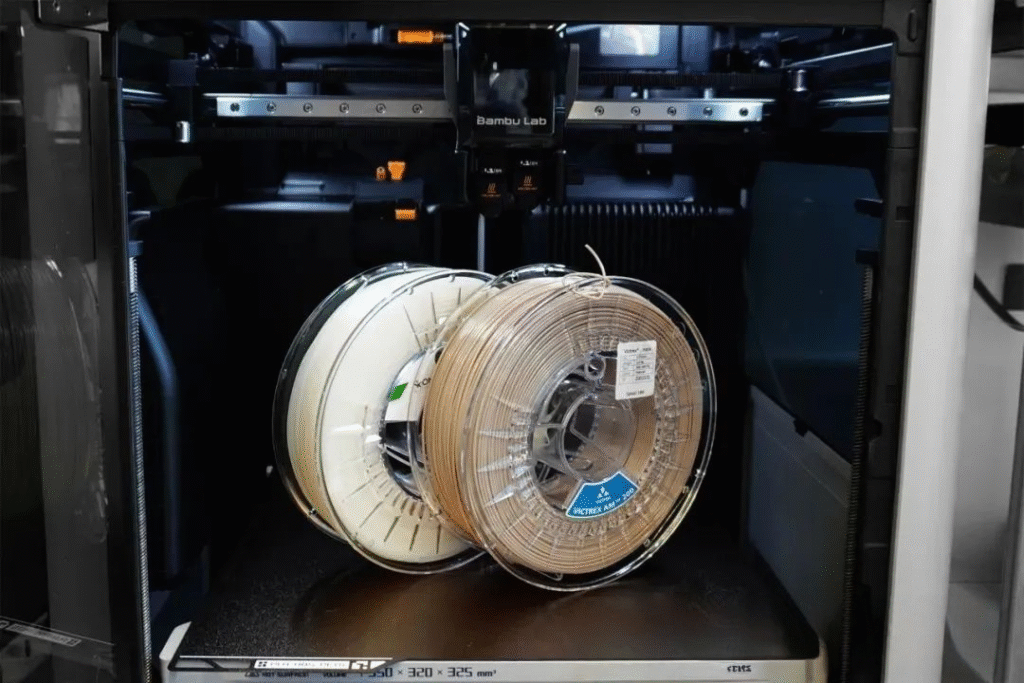

Materials manufacturer Xioneer Systems recently succeeded in 3D printing PEEK parts on Bambu Lab’s H2D printer. The company used Victrex VICTREX AM™ 200 together with its self-developed VXL111 soluble support material, successfully printing and annealing the parts. Xioneer is now working on making PEEK compatible with the H2D AMS material management system.

Robert McKay, Head of New Business Development, Additive Manufacturing, and Emerging Technologies at Victrex, said, ‘When I heard that PAEK had been 3D printed on a Bambu Lab machine, I could hardly believe it!’

Xioneer responded, ‘For us, this is a reminder to always keep doing things that seem theoretically impossible.’

The Bambu Lab H2D is equipped with dual nozzles, which brings the direct benefit of significantly reducing the time and material waste involved in switching between materials. In this case, one nozzle can print PEEK while the other prints the support material.

H2D Printing Process and Nozzle Switching

PAEK materials are notoriously difficult to 3D print, as it is challenging to find a suitable processing window. Taking PEEK — one of the materials in this family — as an example, it has a very high melting point and a glass transition temperature of 143 °C, with a melting point reaching 343 °C, making it extremely difficult to process. Whether using FFF/FDM extrusion or SLS sintering, printing temperatures typically approach 400 °C, and extremely stable and uniform thermal conditions are required.

Successful 3D printing of PEEK depends on controlling its crystallization process. Due to partial crystallization, the material’s density changes, so it is necessary to maintain high temperature levels and avoid temperature fluctuations. In the extrusion process, the nozzle temperature must remain around 400 °C, the chamber should be heated to about 100 °C, and the build plate heated to around 200 °C to minimize warping during printing and to allow for uniform crystallization of the printed parts.

The Bambu Lab H2D has a maximum nozzle temperature of 350 °C, a heated bed temperature of up to 120 °C, and supports active chamber heating with a maximum controllable temperature of 65 °C. Together with its high-temperature hotend, it effectively suppresses warping when printing high-performance materials such as ABS and PC.

Xioneer’s success in printing PEEK on the H2D is indeed impressive, but frequently pushing the machine beyond its specified limits could potentially cause damage. On the other hand, this also prompts industry observers to speculate that the barrier for Bambu Lab to launch a true industrial-grade machine might actually be quite low.

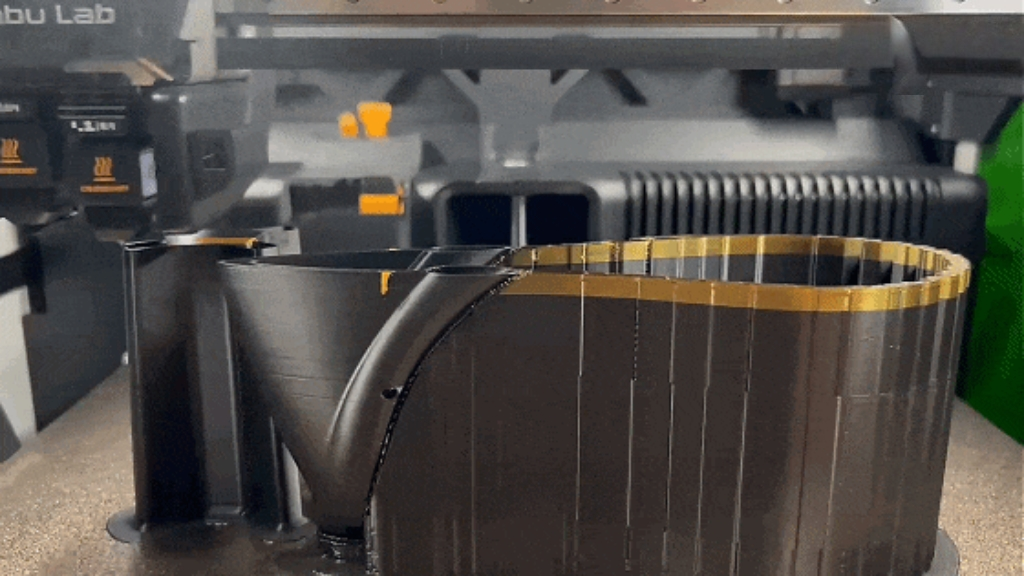

VICTREX AM™ 200 3D-Printed Sample

Victrex AM™ 200 was originally designed as a PEEK material for material extrusion. Thanks to its improved interlayer bonding and dimensional stability, this semi-crystalline material is relatively easier to process. The LMPAEK variant is known as Low-Melt Polyaryletherketone (LMPAEK) or Victrex UDTAS4-143-34. Typically, a nozzle temperature of around 215 °C is required to process PEEK, and the chamber temperature can be lower. It is still unclear whether Xioneer made significant modifications to the H2D machine for this achievement.

Although PEEK is a highly demanding material, it must be said that it offers manufacturers outstanding mechanical and chemical properties: it is highly heat-resistant, wear-resistant, chemically resistant, sterilizable, and has excellent dielectric properties. PEEK also boasts a high strength-to-weight ratio, allowing it to replace certain metals. In addition, its inherent flame retardancy makes it a highly attractive 3D printing material for industries with stringent fire and smoke requirements, such as aerospace.

Looking ahead, it may become possible to 3D print PEEK, PEKK, PEI, and other high-performance materials on affordable machines. This would also mean that consumers could produce PA12 or other high-performance components right at home.