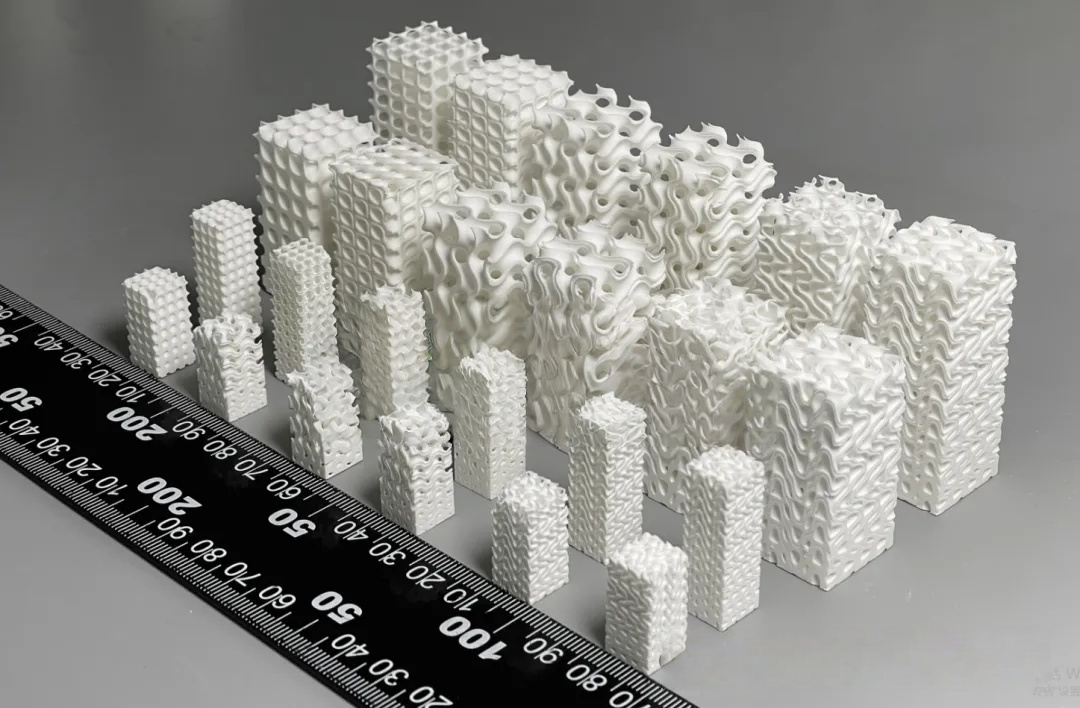

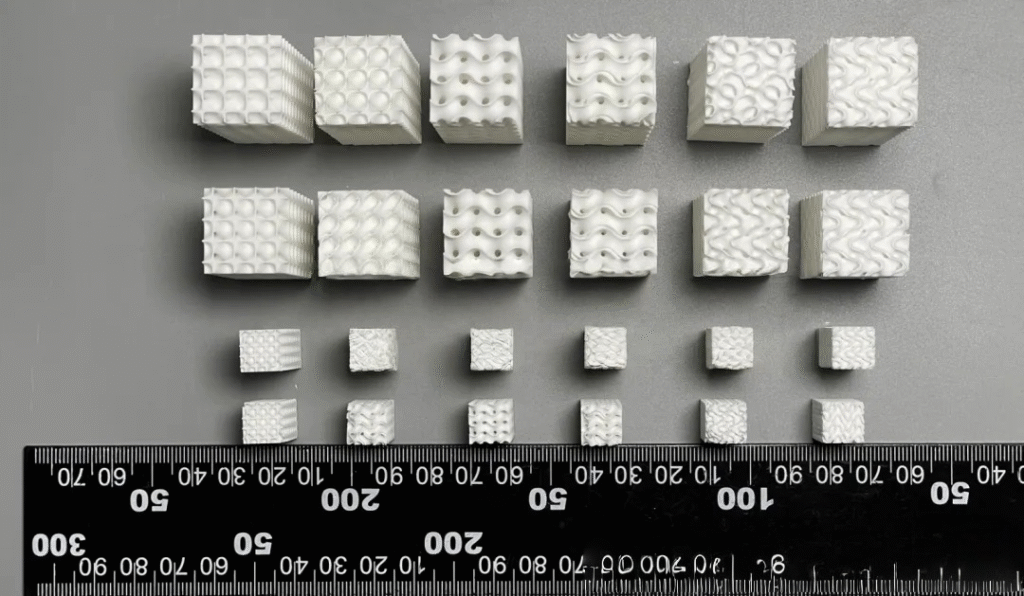

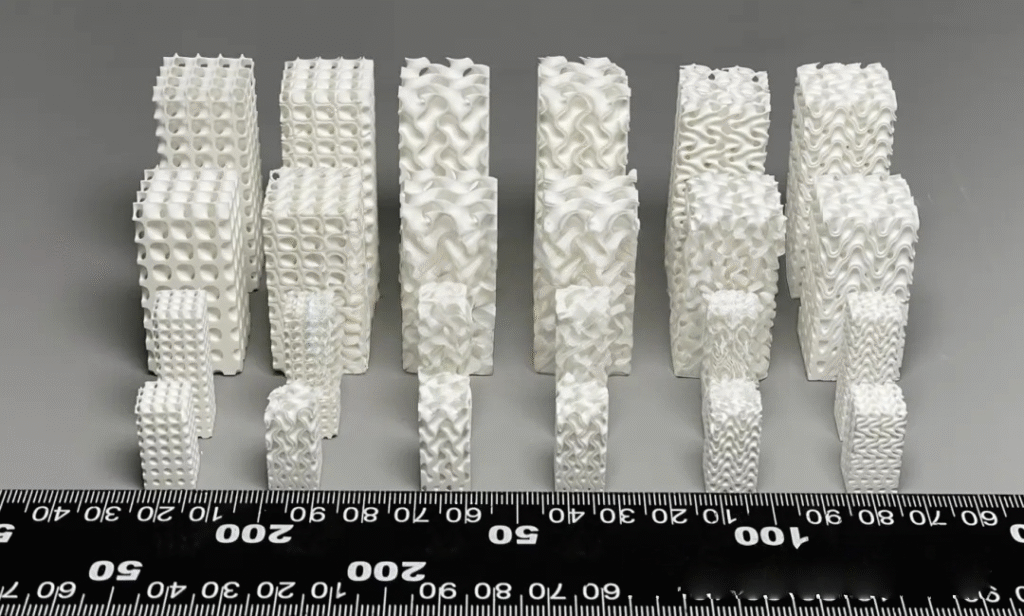

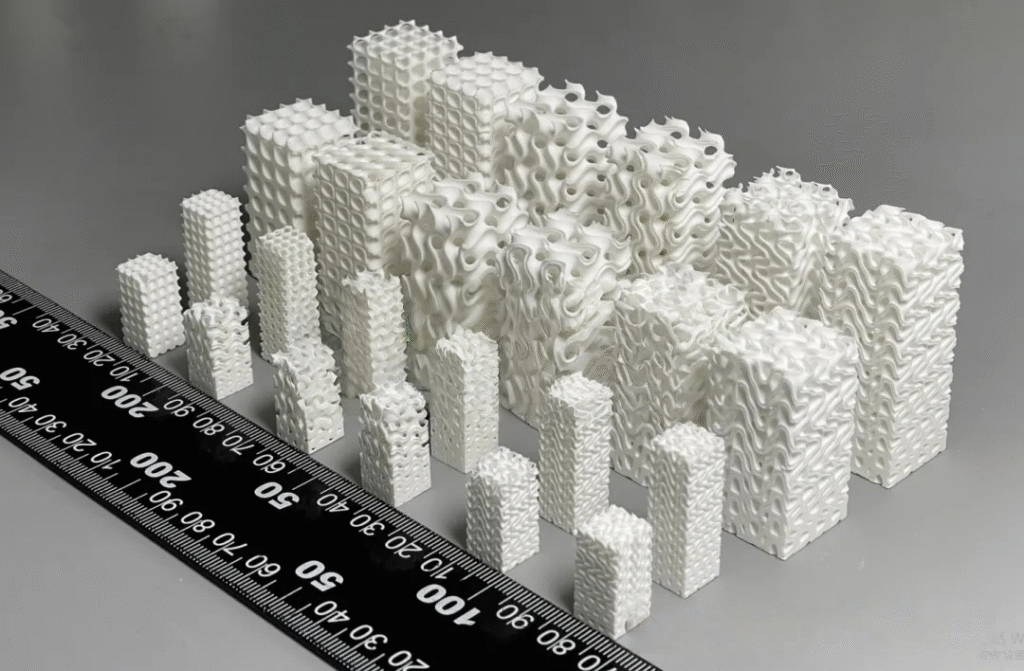

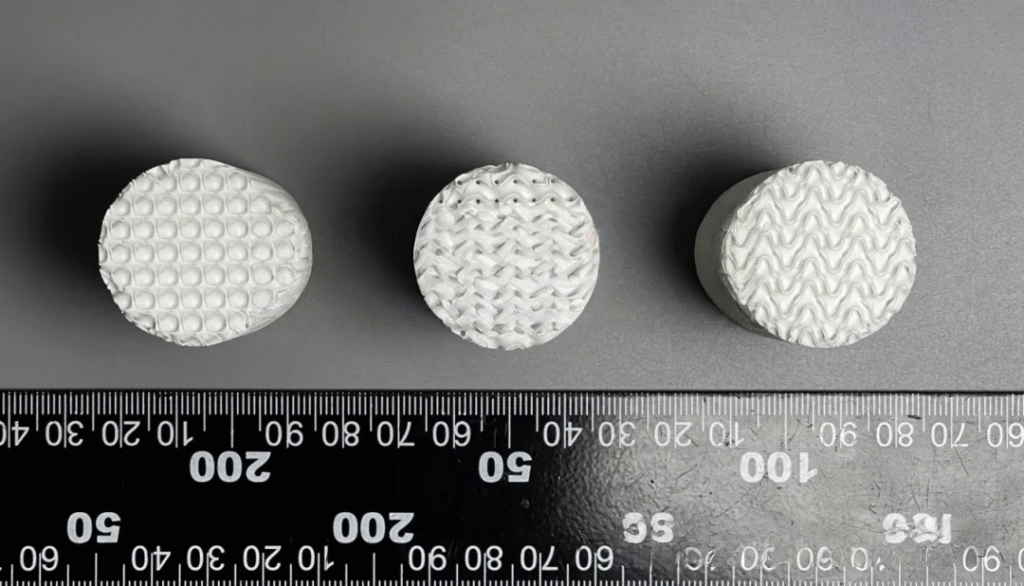

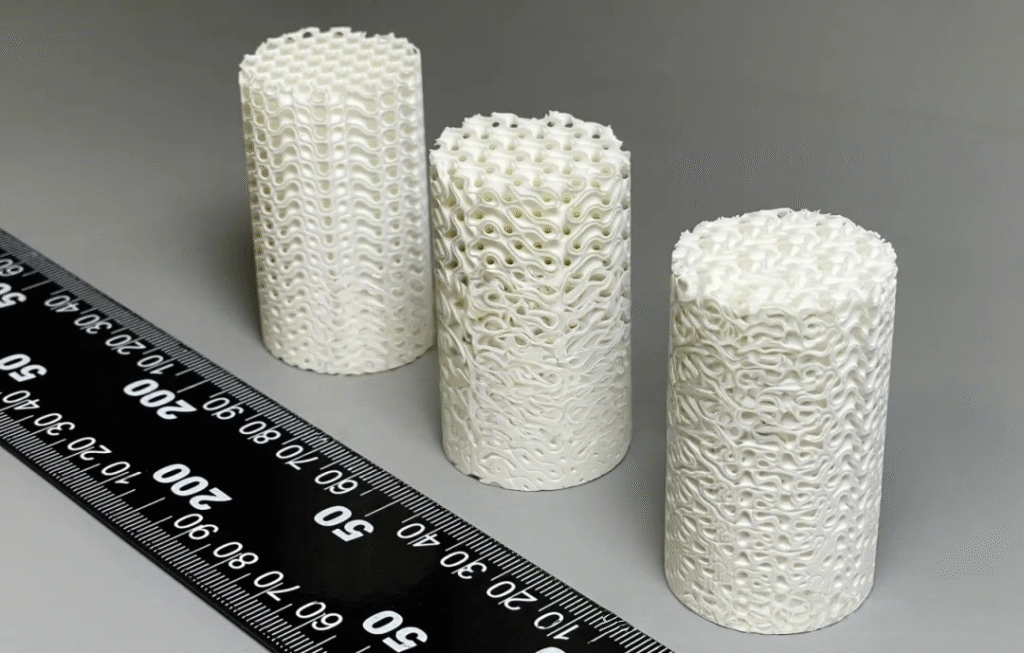

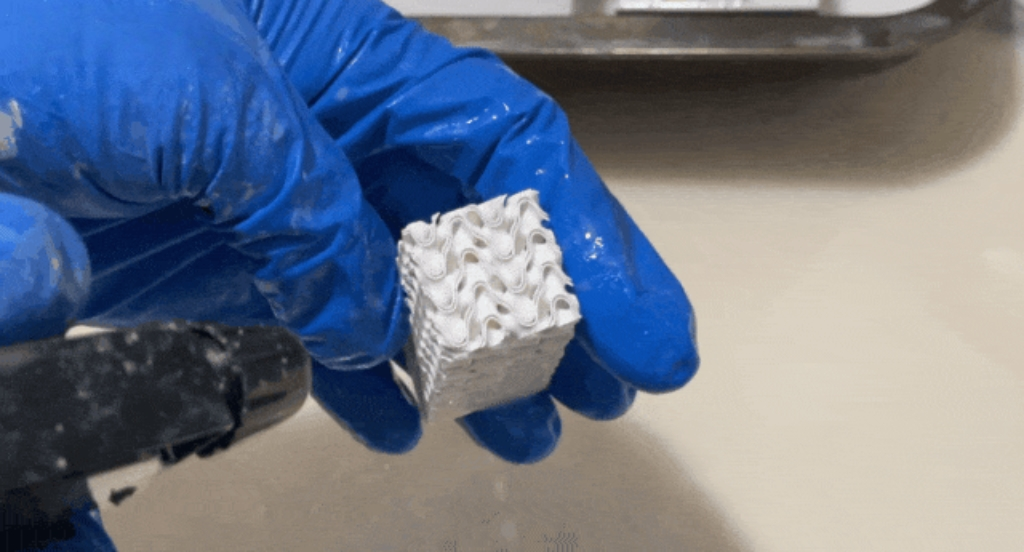

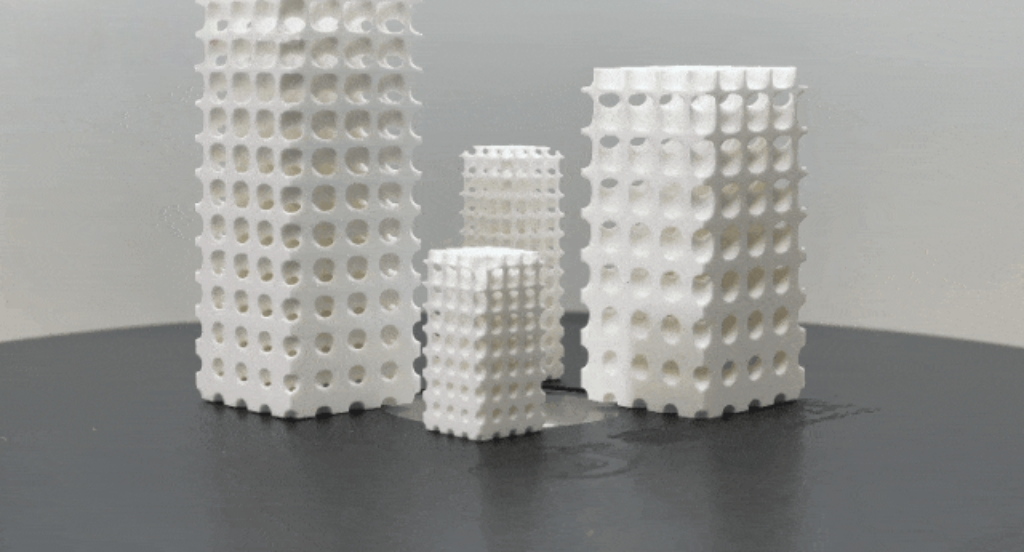

At the forefront of advanced ceramic manufacturing, complex porous structures are becoming essential for testing material properties and expanding application boundaries. The samples shown in the image are made of zirconia, fabricated using DLP ceramic 3D printing technology. They take the form of cylinders, cubes, and other geometries—featuring intricate three-dimensional interconnected pores. These pores not only serve as research objects for mechanical and thermal performance studies but also provide experimental foundations for future biomedical and engineering applications of functional ceramics.

Subtle design variations correspond to different experimental objectives. By using a regularized pore network, these samples create a platform that enables easier parameter comparison and reproducibility. Meanwhile, diverse pore channels and curved geometries offer potential for fluid transport studies, cell adhesion research, and even catalytic applications. Behind these specimens lies a systematic breakthrough in modeling, slurry formulation, and printing process optimization.

As structural optimization and experimental validation progress, zirconia—renowned for its high strength and toughness—is gaining new functionalities and application prospects through 3D printing. From fundamental mechanical research to future applications in orthopedic implants, wear-resistant components, and high-temperature devices, these experimental samples are becoming key starting points for unlocking the multidimensional potential of ceramic materials. Next, let’s take a closer look at the printing process and research developments.

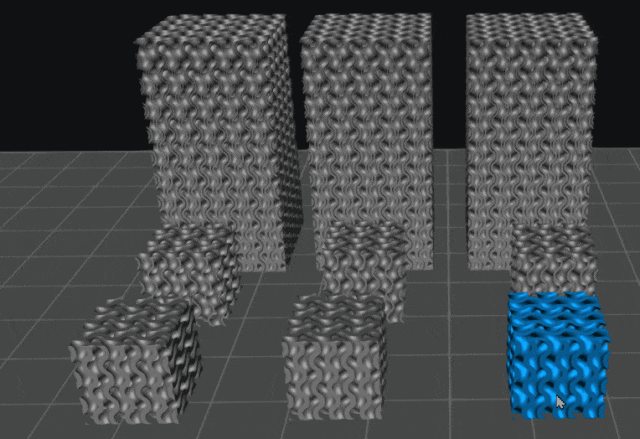

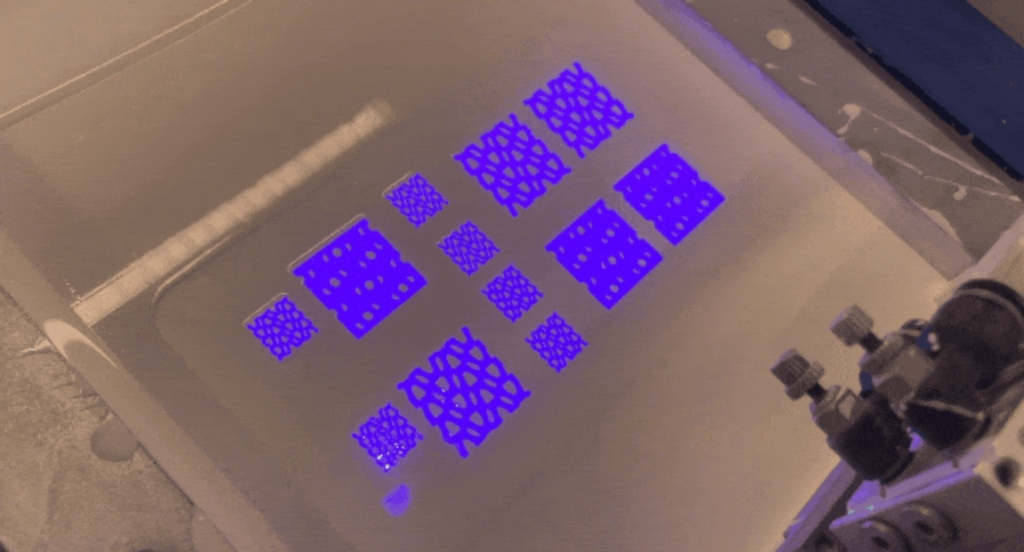

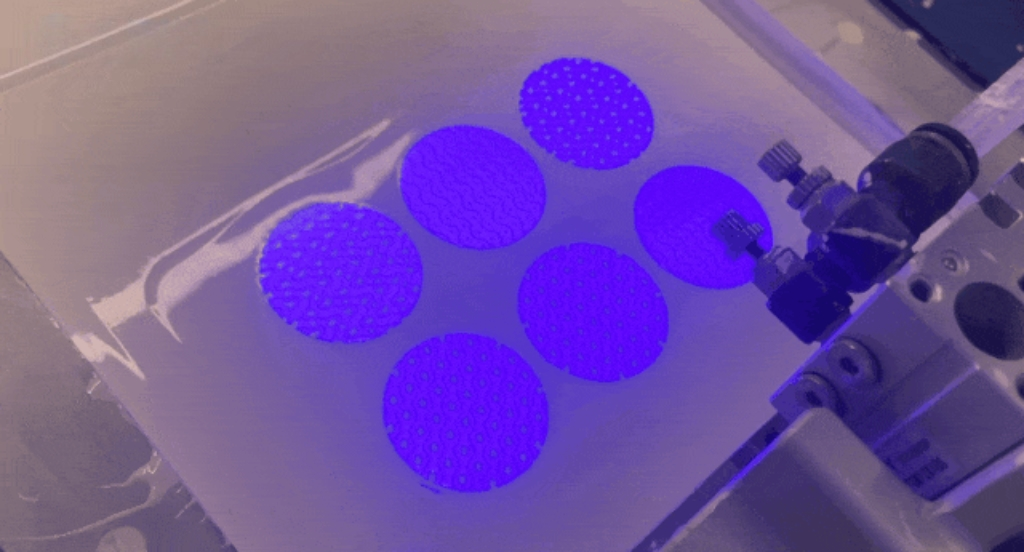

Slicing an STL Model for 3D Printing

3D Printing Process

Printing + Cleaning + Sintering

Light Intensity: 45 mW/cm²

Layer Thickness: 0.05 mm

Exposure Time: 1.5 s

Slurry Recoating Speed: 120 mm/s

Final Product Showcase

Final Product Showcase After Sintering