In its 2025 product lineup, Apple has officially integrated 3D printing technology into its supply chain. Compared to user-facing improvements, this manufacturing shift is expected to have a far greater impact on the entire 3C manufacturing industry.

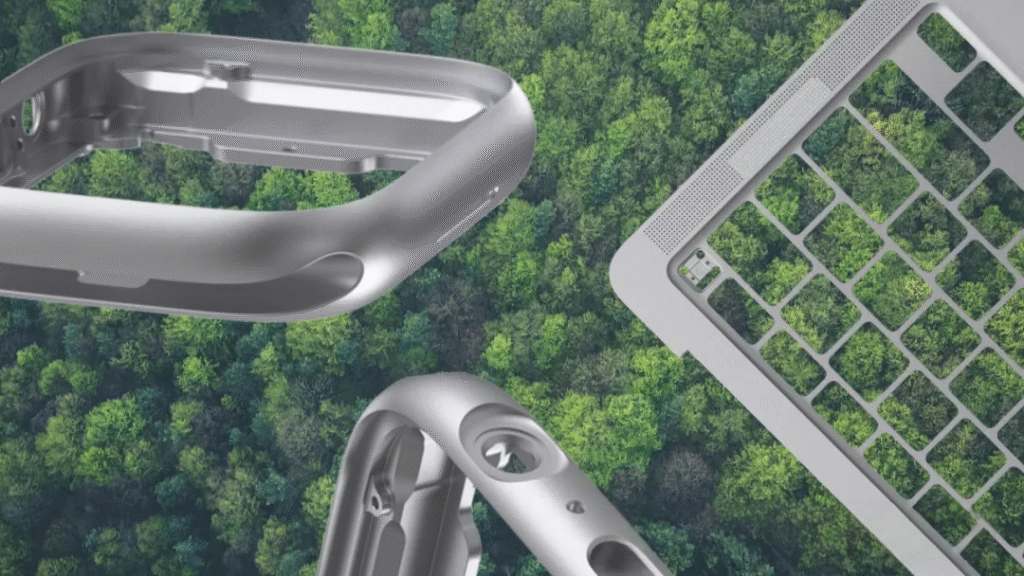

iPhone Air: 3D-Printed Titanium Alloy USB-C Port

Application Part: USB-C port

Manufacturing Advantages: With 3D printing, the port achieves a thinner design and higher strength, enabling iPhone Air to become the thinnest iPhone ever made.

Material Highlights:

Made with 3D-printed titanium alloy, which saves 33% of material use compared to traditional forging;

The device uses 80% recycled titanium, the highest proportion ever in an iPhone;

The battery cobalt is also 100% sourced from recycled materials.

Sustainability in the Supply Chain: 45% of the electricity used in production comes from renewable energy sources such as wind and solar, reinforcing Apple’s low-carbon manufacturing roadmap.

Apple Watch: 3D-Printed Titanium Case

The new Apple Watch Series 11 features a fully 3D-printed titanium case. This design achieves a 40% overall recycled material content, with both aluminum and titanium reaching 100% recycled proportions.

Manufacturing Advantages: The 3D printing process reduces the raw material usage of the titanium case to only half that of previous generations.

Sustainability in the Supply Chain: The entire manufacturing process is powered by 100% renewable energy, including wind and solar power.

Apple’s Focus: Strong Signals of Technological Transformation

From the above information, it is clear that Apple places special emphasis on the concept of “recycled” and “green” manufacturing processes in its new product designs.

Both elements are integral to Apple’s Apple 2030 initiative, which aims to reduce the company’s overall environmental impact. 3D printing, in particular, can significantly cut down on the amount of materials and energy required to produce the same components compared with traditional methods.

Apple 2030 is one of Apple’s most important long-term commitments, targeting carbon neutrality across its entire value chain by 2030. The plan focuses on reducing emissions from three major sources: materials, electricity, and transportation.

The new products launched this fall mark Apple’s first large-scale adoption of 3D printing technology. Following the use of 3D printing in the previous generation of Apple Watch, Apple has expanded the scope of the technology: not only does the Apple Watch 11 continue with 3D-printed titanium cases, but the iPhone Air has also become the first iPhone to incorporate a titanium 3D-printed component, signaling that Apple has officially integrated 3D printing into its supply chain.

The role of 3D printing in mass production of consumer electronics will undoubtedly create a new wave of opportunities for the additive manufacturing industry. The question is: who will seize the lead in this “once-in-a-lifetime” opportunity?

According to 3D Printing Technology Review, the winners are likely to be those companies that:

Emphasize green manufacturing and low-carbon practices, and

Have already made significant progress in overcoming the technical challenges of large-scale additive manufacturing.