Copper and copper alloys, as core conductive and thermal management materials, are widely used in electronics, automotive, power systems, heat dissipation, aerospace, and new energy applications. As these industries continue to grow rapidly, demand for complex structural components is increasing year by year. Traditional manufacturing methods can no longer fully meet these requirements, driving growing interest in 3D printing of pure copper and copper alloy components with intricate geometries.

Electron Beam Melting (EBM), developed in the 1990s, is a metal additive manufacturing technology that utilizes a high-energy electron beam to selectively melt metal powder layer by layer in a vacuum environment, ultimately forming the final component. EBM offers several key advantages, including high energy density, low residual stress, high energy absorption efficiency, fast scanning speed, and operation in a vacuum atmosphere. These features make it especially suitable for forming hard and brittle, high-melting-point materials such as titanium aluminides and tungsten alloys. Additionally, EBM achieves over 90% absorption for highly reflective materials like copper, gold, silver, magnesium, and aluminum, making it highly promising for aerospace, defense, biomedical, and automotive applications.

Compared with Selective Laser Melting (SLM), EBM offers higher energy efficiency and deeper melt pools when forming pure copper and copper alloy components, making it one of the most important and promising approaches for direct 3D printing of such parts.

Challenges of SLM in Printing Pure Copper and Copper Alloys

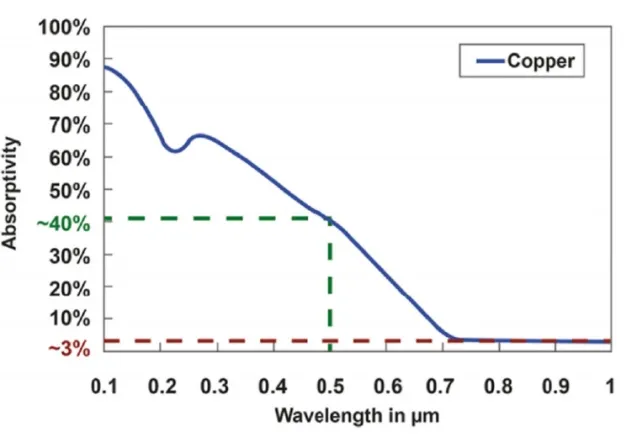

High Reflectivity:

Copper exhibits extremely high reflectivity (~95%) in the infrared spectrum (e.g., at the 1064 nm wavelength commonly used by fiber lasers). This means that most of the laser energy is reflected rather than absorbed, resulting in low energy utilization, insufficient heat input, unstable processing, and difficulty achieving successful builds — particularly with high-purity copper.

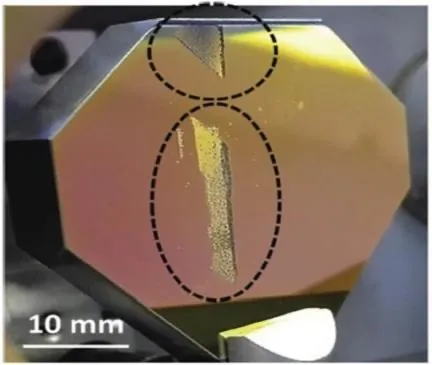

Laser Optics Damage:

The high reflectivity of copper can cause severe damage to optical mirrors, galvanometers, and laser resonator components, making it challenging to achieve reliable, large-scale production.

Advantages of Electron Beam Melting (EBM) for Pure Copper and Copper Alloys

Low Reflectivity Sensitivity:

Unlike lasers, an electron beam is a stream of charged particles and is not affected by the optical reflectivity of copper. This allows highly efficient energy transfer into the copper powder, resulting in excellent energy utilization, sufficient heat input, and highly dense parts. The process ensures a stable, controllable melt pool, making it ideal for manufacturing high-reflectivity materials like copper.

High Vacuum Environment:

EBM is carried out entirely under high vacuum conditions (approximately 10⁻³ Pa). The vacuum effectively prevents oxidation of pure copper or copper alloy powders at high temperatures, ensuring extremely low impurity and oxygen content. The same batch of powder can be reused multiple times without quality degradation.

Low Residual Stress:

Due to layer-by-layer preheating inherent in the EBM process, residual stresses caused by rapid heating and cooling are greatly minimized. This prevents deformation and cracking, resulting in excellent internal quality and high yield rates. EBM is particularly well-suited for large or geometrically complex copper components.

High Production Efficiency:

With electron beam power reaching several kilowatts and extremely fast beam deflection—far exceeding the scanning speed of laser galvanometers—EBM can melt copper powder rapidly. This significantly boosts build speed, especially advantageous for batch production of large, dense components.

Superior Material Properties:

EBM-printed pure copper and copper alloy parts exhibit high purity, exceptional density, and excellent electrical and thermal conductivity, enabling performance combinations that are difficult to achieve with conventional manufacturing methods.

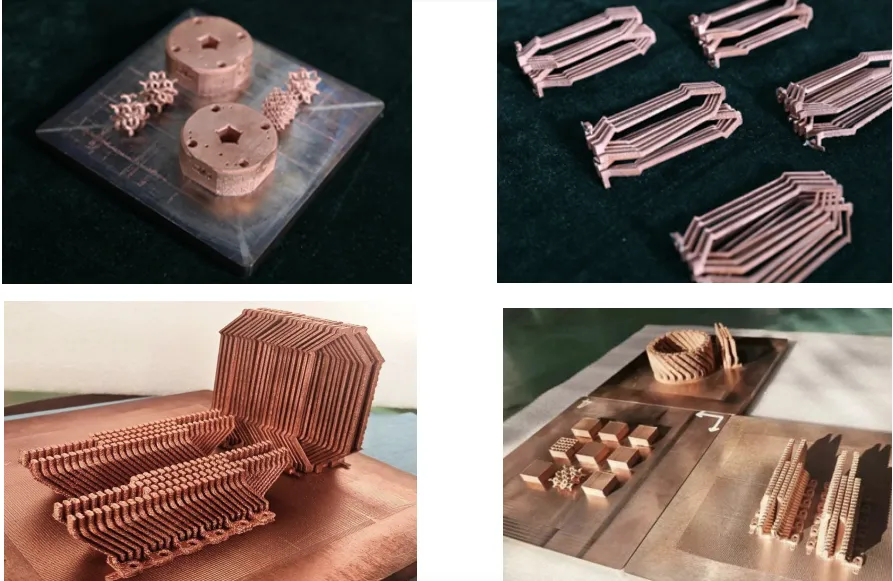

High Design Freedom:

EBM enables the production of copper components with intricate internal features, such as conformal cooling channels and lattice structures, achieving lightweight and functionally integrated designs that are impossible to manufacture using traditional techniques.

Applications of EBM for Pure Copper and Copper Alloys

Electric Drive Systems – 3D-Printed Motor Windings:

EBM allows motor windings with significantly greater design freedom. Higher copper fill factors in stator slots improve thermal coupling, reduce rotor losses, and increase overall motor efficiency.

Typical 3D-Printed Additive Manufacturing Motor Windings

Advanced Thermal Management – 3D-Printed Heat Sinks and Nozzles

3D-printed heat sinks and heat exchangers offer significantly greater design freedom, enabling nearly double the cooling performance while reducing weight by approximately 20% and improving overall efficiency by around 20%.

For aerospace applications, 3D-printed combustion chambers and nozzles are designed as integrated components, which not only deliver superior cooling performance but also minimize the number of individual parts and assembly steps required.

Typical 3D-Printed Additive-Manufactured Heat Sink

Typical 3D-Printed Additive-Manufactured Combustion Chamber and Nozzle

Potential Application – 3D-Printed Induction Coil

3D-printed induction coils can be manufactured as a single integrated part without manual bending or welding, eliminating fatigue cracking and other issues caused by welding. This significantly improves service life and operational stability. In addition, they offer greater design freedom, enabling geometric optimization to enhance electrical conductivity and thermal performance.

Pure Copper and Copper Alloy Samples Fabricated by Electron Beam Melting