Imagine this: the same car bumper that “softens up” to absorb energy during a low-speed scrape—reducing repair costs—can instantly “tighten up” during a high-speed collision, protecting the cabin from intrusion. Traditional automotive safety components can only deliver a fixed force–displacement curve, forcing engineers to compromise between comfort and safety.

However, a recent study published in Advanced Materials presents a breakthrough alternative — a 3D-printed twisted lattice metamaterial. This innovative structure can adaptively deform under different impact speeds, exhibiting entirely different mechanical responses depending on the situation — as if the material itself could “think.”

At its core lies a helically structured low-alloy hardened steel lattice, which undergoes a controlled transformation into a twisted configuration under axial compression. The goal is to create a component capable of switching between rigid support and soft damping modes — all without the need for actuators, sensors, or fluid systems.

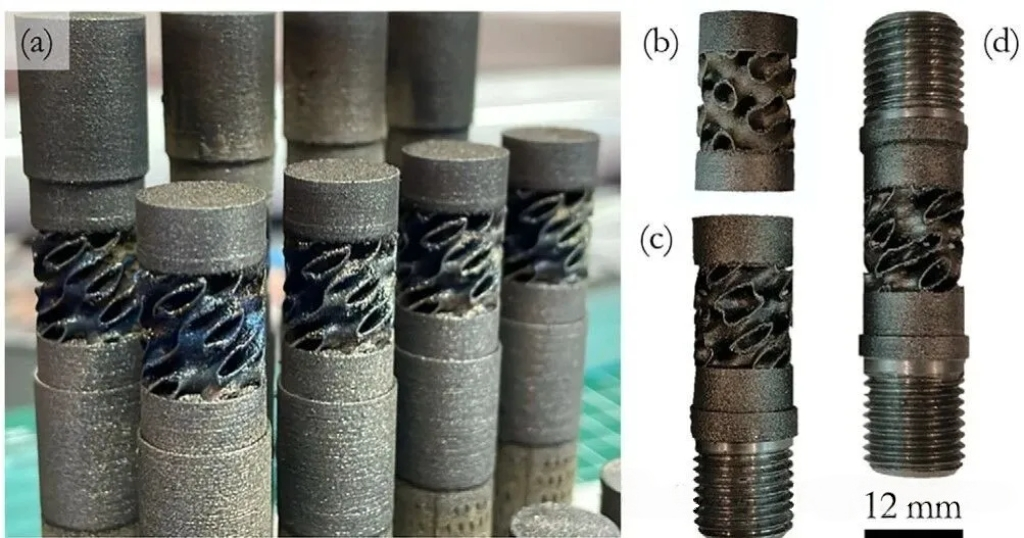

3D-Printed Twisted Lattice Structure

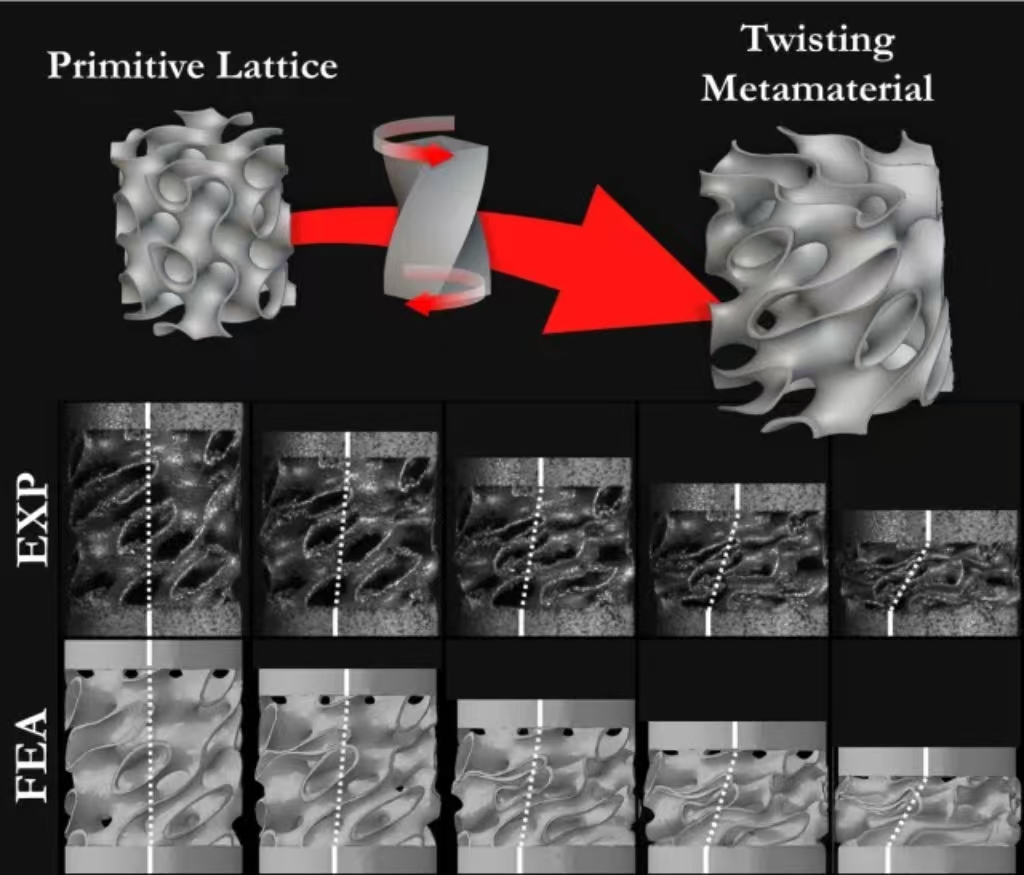

From a technical perspective, the structure is a highly porous helical topology fabricated using LPBF (Laser Powder Bed Fusion) metal 3D printing. This periodic design integrates both translational and rotational motion: when the component is compressed, it undergoes a controlled helical twist, effectively dissipating impact energy.

When rotation is constrained, the lattice exhibits maximum stiffness and a peak specific energy absorption of 15.36 joules per gram. Once rotation ceases, both stiffness and energy absorption drop by about 10%, while excessive twisting leads to an approximate 33% reduction in energy absorption. This tunable response enables customized crash behavior based on load conditions, installation space, and rebound characteristics.

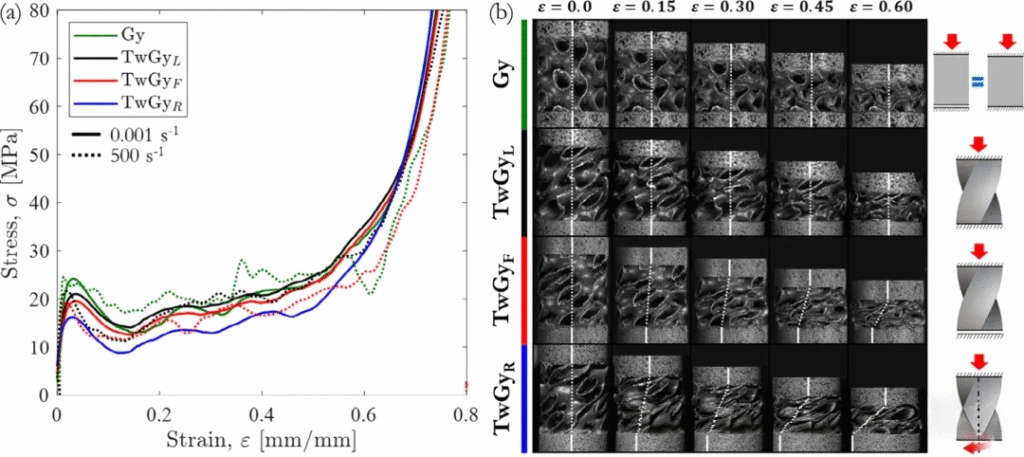

Quasi-Static and Dynamic Compression Behavior of the Gyroid Structure (ρ¯ = 10%)

The study was conducted by researchers from the University of Glasgow (UK), Marche Polytechnic University (Italy), University of L’Aquila (Italy), and the Italian National Institute for Nuclear Physics (INFN). The team achieved precise structural control of the material, enabling the creation of a complex and highly porous helical lattice. They believe this material could significantly enhance vehicle crash protection.

Unlike conventional foams or crumple zones that provide a fixed impact resistance, this material’s response to impact can be mechanically tuned, altering its energy absorption behavior. As a result, the impact response can be fine-tuned—offering greater resistance during severe collisions or softer cushioning in minor impacts.

Effect of Geometric Variations on the Twisting Gyroid Structure

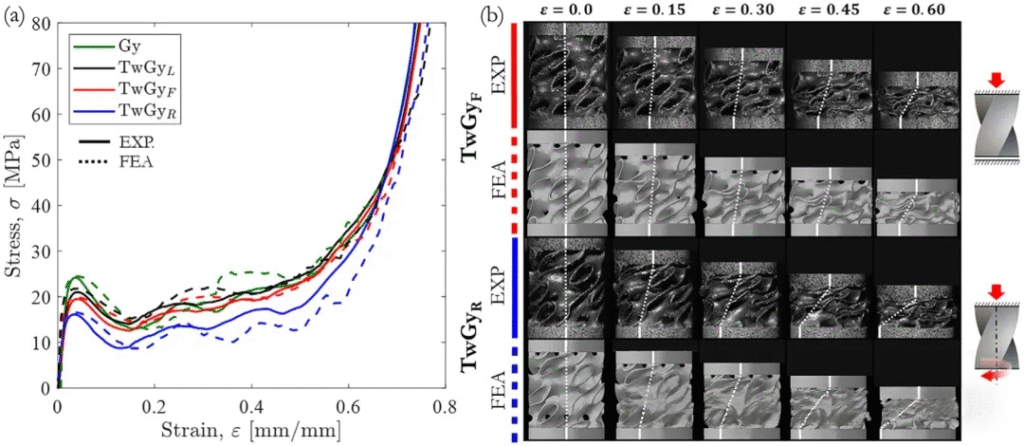

The results show that the material has the potential to provide multiple protective functions, ranging from rigid shielding to softer energy absorption. The findings are supported by a comprehensive theoretical and computational model capable of accurately predicting the complex behavior of the twisting helical lattice under different strain rates.

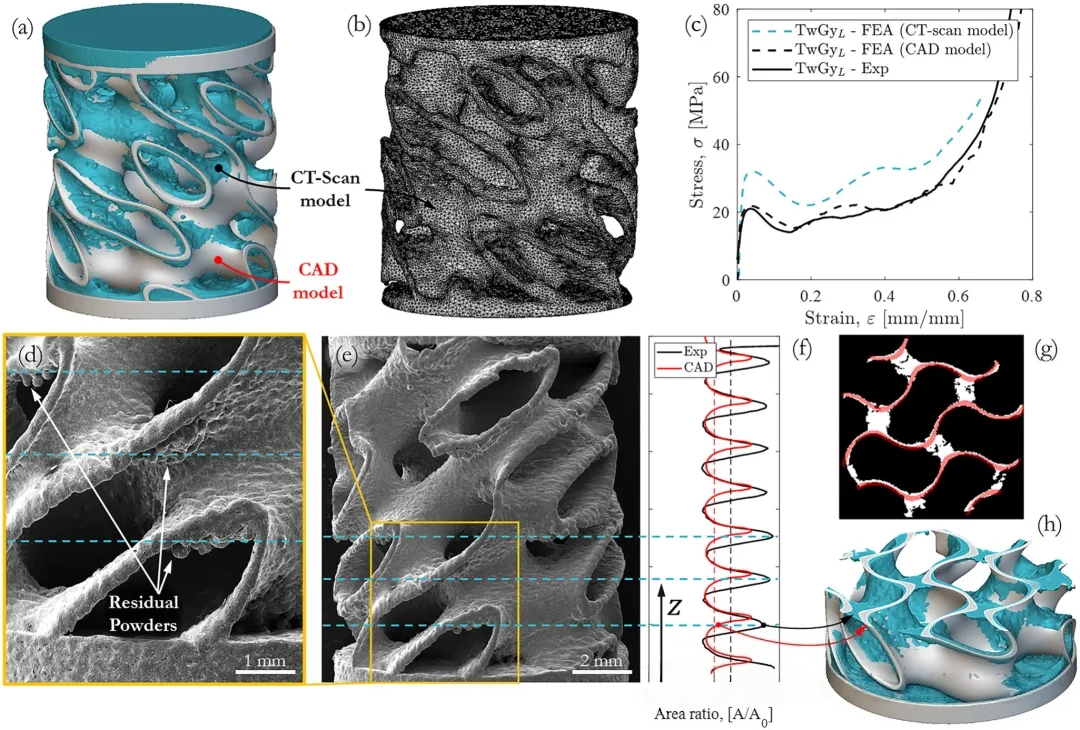

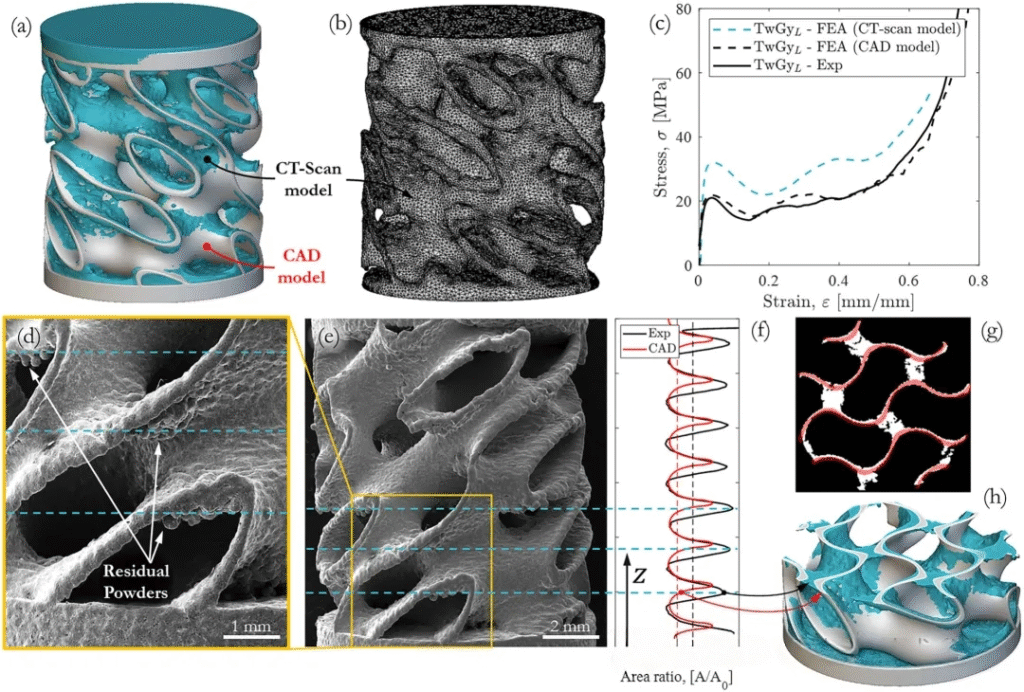

To achieve precise numerical–experimental calibration, the researchers integrated micro-CT reconstruction data of the printed lattices to quantify geometric imperfections introduced during the additive manufacturing process.

Quasi-Static Compression Behavior of the Gyroid Structure with a Relative Density of ρ¯ = 10%: Experimental and Finite Element Predictions

The study was led by Professor Shanmugam Kumar from the James Watt School of Engineering at the University of Glasgow. He explained:

“Most protective materials currently used in vehicles are static — they are designed for specific impact scenarios and cannot adapt to changing conditions. This research introduces adaptive twisting metamaterials, a new class of materials capable of self-adjustment without any complex electronic or hydraulic systems. Instead, they adapt purely through mechanical rotation control. When compressive force is applied, the helical lattice converts it into torsion. By altering boundary conditions, we can tune the energy absorption characteristics. These materials can adjust and modify their properties based on the type and severity of impact, thereby reducing damage.”

He further added:“We believe this material could be applied in future automotive and aerospace safety systems, offering a new type of structure that adapts to different requirements as needed. Moreover, by converting impact energy into rotational kinetic energy, it could even enable new forms of energy harvesting.”