With the advent of metal 3D printing technology, the research and production of rotating detonation rocket engines (RDEs) have made remarkable progress. In November 2025, RTX achieved a major breakthrough in RDE development. This propulsion technology—long discussed in theory but rarely validated at scale—is now rapidly becoming a reality, and additive manufacturing is the key driving force behind this transformation.

Complex Structures Beyond Traditional Manufacturing — Effortlessly Achieved by Metal 3D Printing

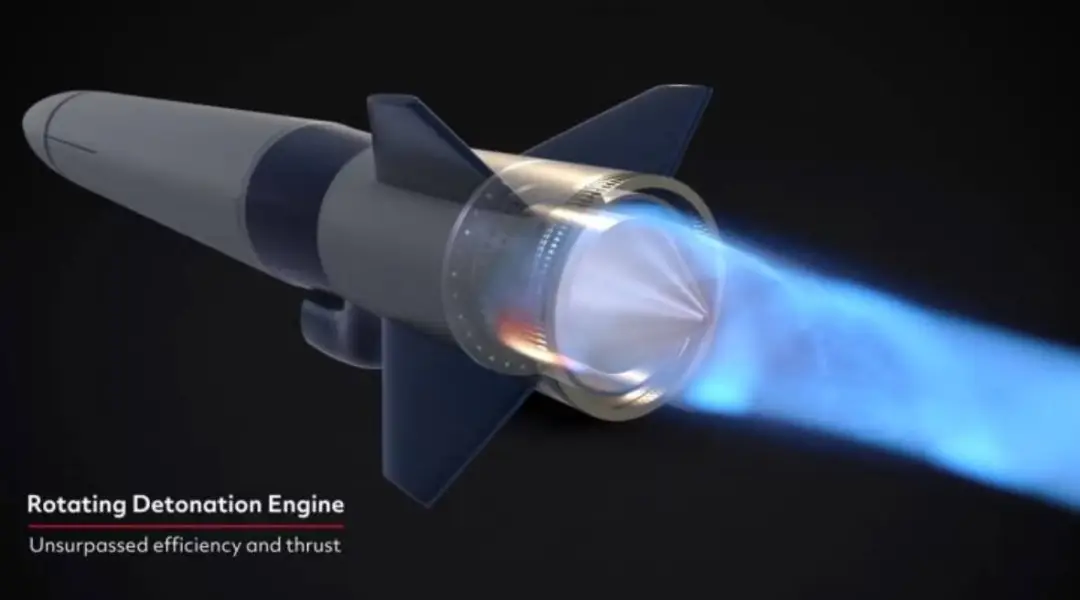

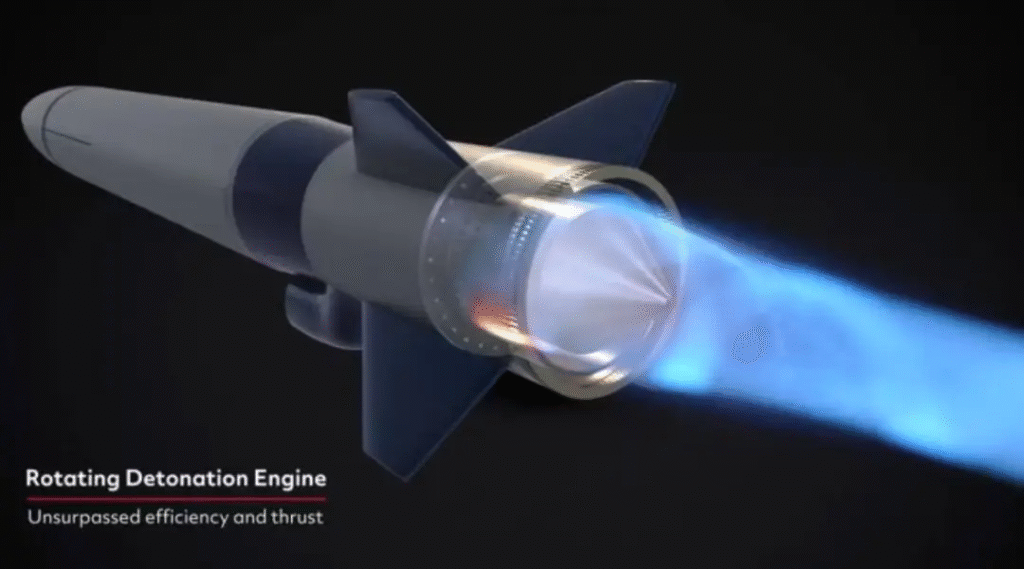

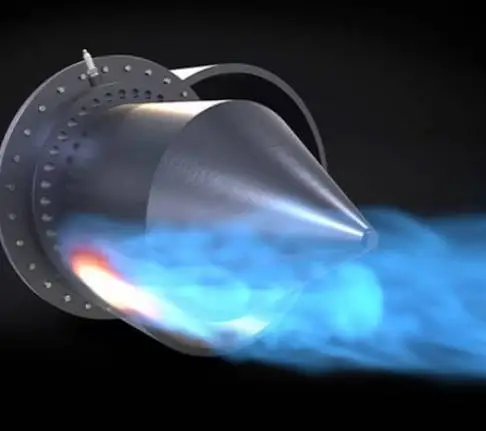

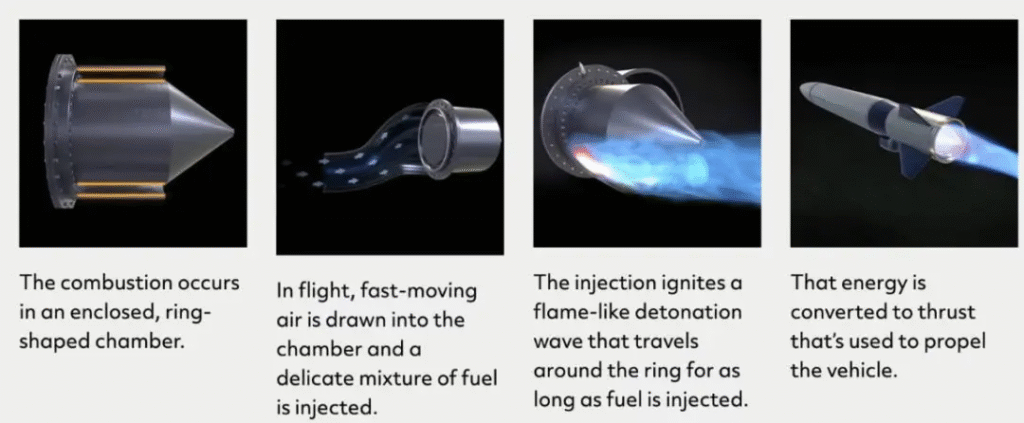

The rotating detonation engine (RDE) operates by maintaining a continuously rotating detonation wave within an annular combustion chamber, generating thrust. This design eliminates the need for traditional turbomachinery, theoretically providing higher thrust and fuel efficiency.

However, achieving a stable detonation wave requires extremely precise fuel–air mixing, highly optimized combustion chamber geometry, and materials capable of withstanding extreme temperatures and pressures.

In the past, such intricate internal geometries were nearly impossible to fabricate using conventional machining methods. With metal 3D printing, RTX engineers can now rapidly produce test components featuring fine channels and microstructures, allowing for iterative optimization through multiple test cycles. Each round of test data feeds directly back into the next design iteration — dramatically shortening the R&D timeline.

Fuel Injection System

Steven Burd, Chief Engineer for Advanced Military Engines at Pratt & Whitney, pointed out that the fuel injection system design was one of the most challenging technical aspects of the entire project.

He explained:

“It’s like an art — we have to fine-tune it repeatedly to consistently reproduce the ideal detonation conditions. Without the design freedom offered by 3D printing, our team could never have iterated the combustion chamber and nozzle geometries so quickly, let alone reached the desired performance targets.”

RTX Collaboration Accelerates Implementation

The project was initially funded by the U.S. Air Force Research Laboratory (AFRL), with RTX mobilizing multiple divisions to work in concert:

The RTX Technology Research Center in Connecticut led the early-stage fundamental research;

Pratt & Whitney spearheaded the engineering maturation of the full engine system;

Raytheon focused on integrating RDE technology into future hypersonic missile and other combat platforms.

This integrated “research–production–application” model has greatly accelerated the transition of rotating detonation engine technology from laboratory experiments to real-world deployment.

Beyond Prototypes: 3D Printing Poised for Final Production of RDEs

Beata Maynard, Deputy Director of Pratt & Whitney’s Advanced Military Engines division, emphasized that additive manufacturing will not remain confined to prototyping. In the future, the technology will be used for the formal production of rotating detonation engines (RDEs). Engineers are using newly acquired test data to validate simulation models while simultaneously leveraging 3D printing to co-optimize design and manufacturing processes.

Because RDEs are compact and have very high power density, installing them in missiles can free up substantial internal volume—space that can be repurposed for additional fuel, extra sensors, or increased payload, delivering significant tactical advantages.

Test Results Exceed Expectations

Chris Hugill, lead of the Pratt & Whitney GATORWORKS development team, revealed that the latest round of ground tests performed far beyond expectations. “These results strongly validate the value of continued investment,” he said. “Our next steps are full-system ground integration tests, followed by flight testing.” Despite the high complexity of RDE technology, the RTX team believes this disruptive propulsion architecture is now within practical reach.