Coating technology has been proven to significantly enhance the performance of 3D-printed plastic parts, thereby increasing the added value of such components, which also holds important implications for the aerospace field.

Recently, significant progress has been made in the certification of micro-additively manufactured components with metallic coatings. The components were subjected to simulated radiation exposure equivalent to approximately four years of operation in low Earth orbit. This effort aims to evaluate the adhesion strength of the electroplated metal layer on the polymer substrate and the aging behavior of the substrate under ionizing radiation. The research findings address two critical issues in aerospace certification. First, the coating maintained complete adhesion and structural integrity throughout the exposure period, showing no signs of delamination or cracking. Second, as anticipated, the brittleness of the polymer increased.

The severity of this embrittlement and whether it leads to failure are directly related to the component’s geometry, load conditions, and operational environment. Since the maximum mechanical loads on parts typically occur during rocket launches, simulations based on this scenario can be used to determine the allowable operational limits for specific components. This research was conducted by Horizon Microtechnologies (HMT), a Germany-based company specializing in coating process development. The coating technology developed by HMT is applicable to components with highly complex geometries and a variety of substrates, effectively balancing the trade-offs between material properties, functional requirements, and manufacturability.

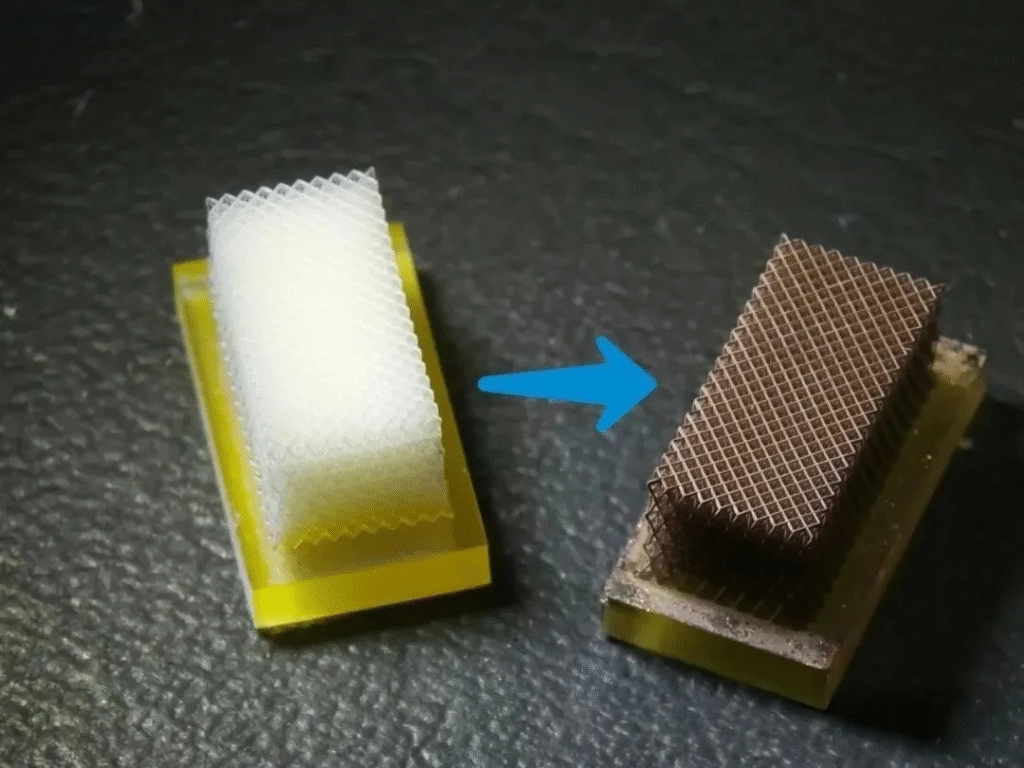

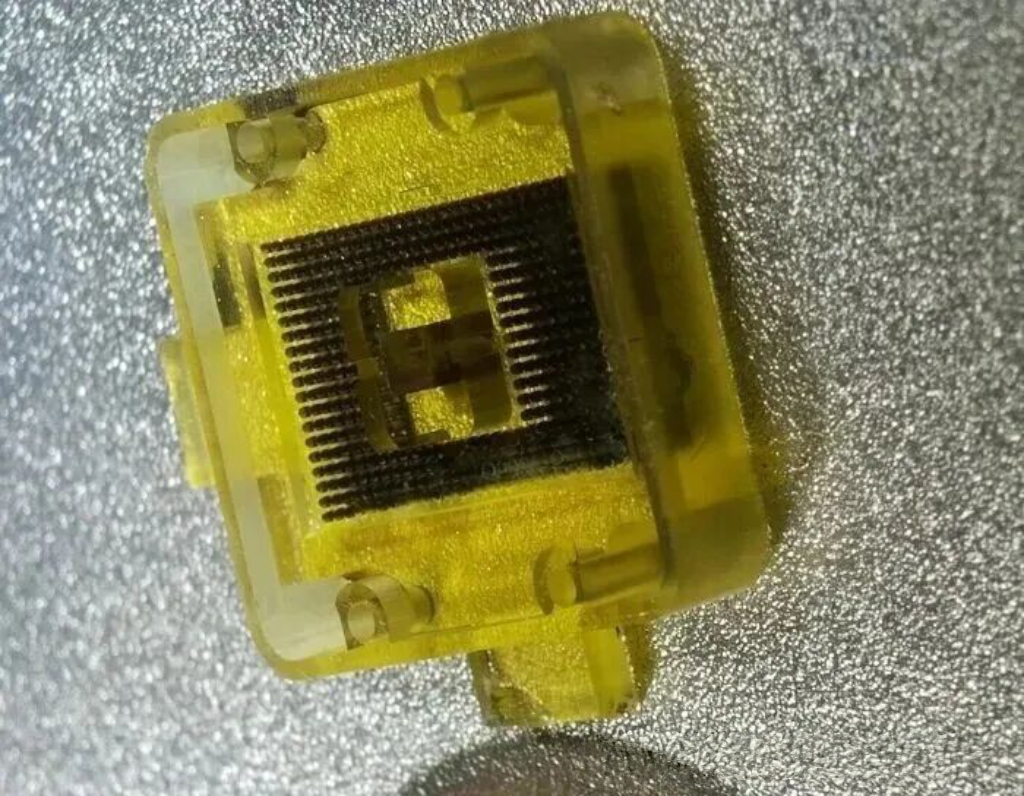

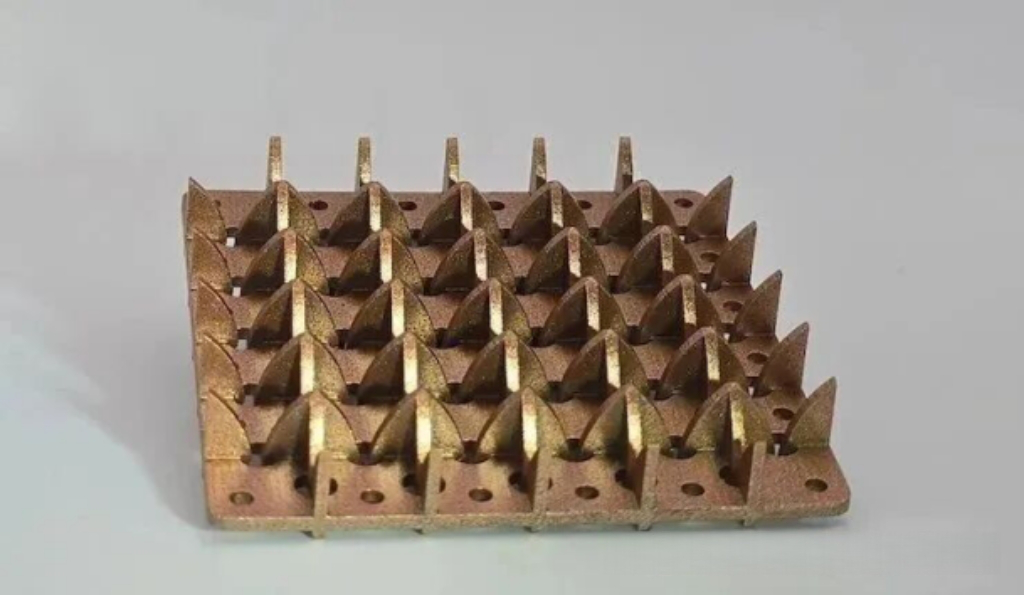

HMT states that its coating technology is particularly suitable for the post-processing of micro 3D printed polymer parts. This not only allows for the full utilization of the design freedom, precision, and resolution enabled by micro-additive manufacturing but also seals the parts through the coating process, enabling them to adapt to corrosive chemical environments, conduct electricity, provide shielding, and in some cases enhance their resistance to high temperatures, mechanical loads, or wear.

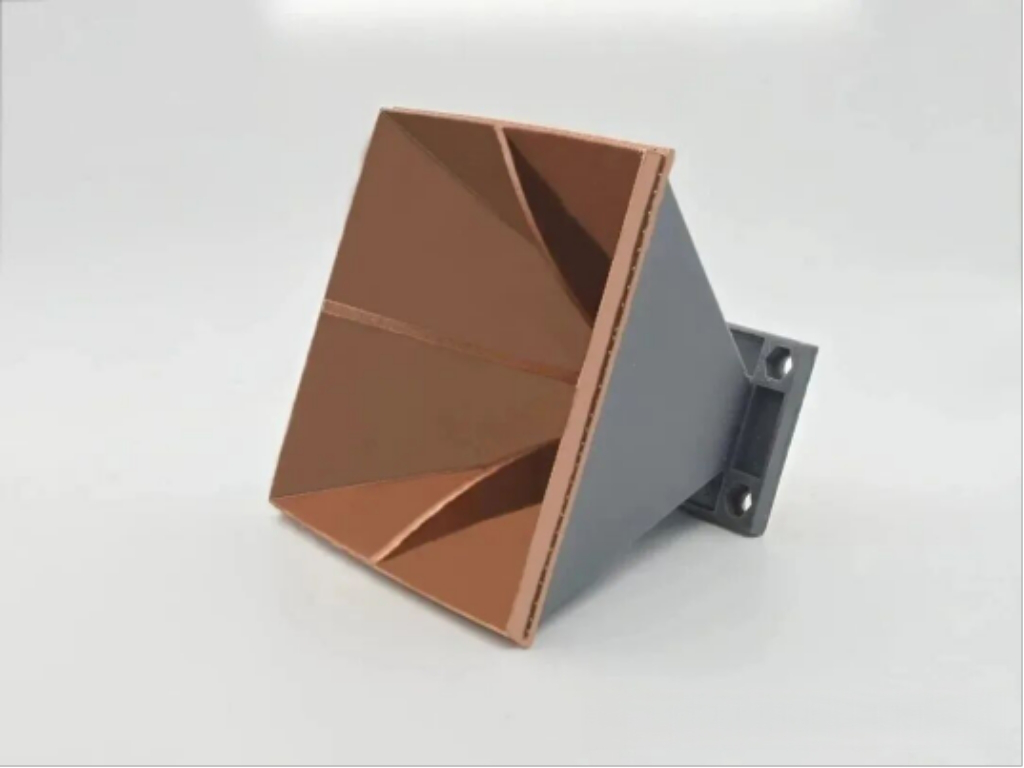

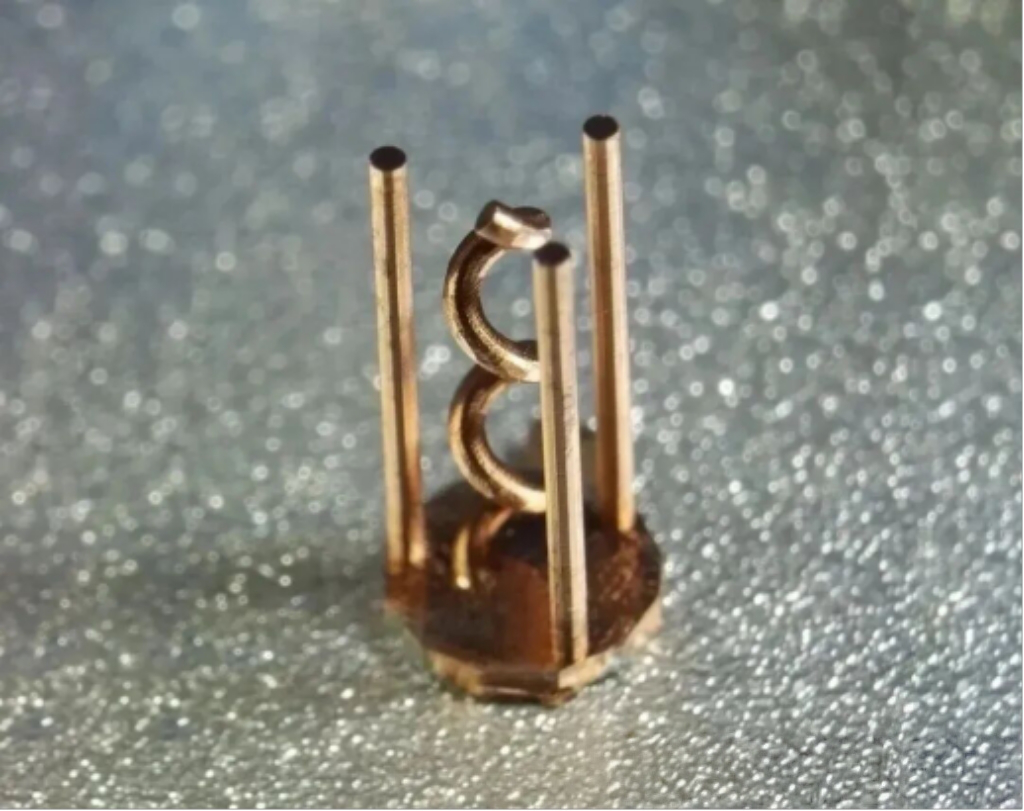

A 3D printed socket is being tested after undergoing metal coating treatment. HMT notes that its coating process is capable of handling deep grooves, undercuts, and long, curved internal channels in micro 3D printed parts. When combined with 3D printed components, it enables the free manufacturing of nozzles and microfluidic systems. Parts produced through this combined process can operate effectively under conditions of high flow rates, high-pressure drops, corrosive solvents, and exposure to certain acids and bases. HMT recently announced a new breakthrough, where it integrated DLP technology with coating technology to develop an antenna that is six times lighter than comparable products, securing funding from the European Space Agency. The company uses BMF Precision’s S240 DLP 3D printer to manufacture the parts, which are subsequently coated with silver, copper, and other metals on the surface.

The company has now passed the ECSS-Q-ST-70-02C outgassing test standard. This standard, developed by the European Cooperation for Space Standardization, determines the suitability of materials for use in spacecraft. According to 3D Printing Technology Reference, for coated parts used in space, if outgassing occurs, it can damage the impregnated coating, leading to warping or deformation of the components, which poses a significant challenge for space material applications. According to the testing standard, the sample is placed in a vacuum environment of 10⁻⁶–10⁻⁷ mbar, exposed to 125°C for 24 hours, and weighed before, after, and 24 hours after the test concludes. The purpose of this procedure is to determine whether the component releases or absorbs other volatile substances and to quantify the amounts. In addition, the mass change of the adjacent test plate is measured, as volatile substances released by the sample may condense on it. This also verifies whether the coated components could contaminate nearby parts under high-temperature conditions. The above data is quantified as Total Mass Loss (TML), Recovered Mass Loss (RML), and Collected Volatile Condensable Materials (CVCM). The results showed that these three indicators were 0.354%, 0.166%, and 0.000% respectively, fully complying with the acceptance limits defined for spacecraft materials.

This result further confirms that the combination of 3D printed materials and coatings can provide the necessary reliability and material stability to meet stringent application requirements. Previously, applying coatings to 3D printed components has faced skepticism due to issues such as outgassing, delamination, and surface brittleness. The tests conducted demonstrate that these challenges can be effectively overcome.