Compared to traditional machining, 3D printing allows for the creation of more complex structures. For hydraulic manifolds, it enables further optimization of internal flow channels, allowing for smoother fluid flow, reduced pressure drop, and removal of unnecessary material, while still maintaining strength and reliability.

✅ Weight reduction of up to 60%

✅ Compact design, suitable for tighter spaces

✅ Reduced leak paths by integrating components

✅ Faster prototyping and production cycle

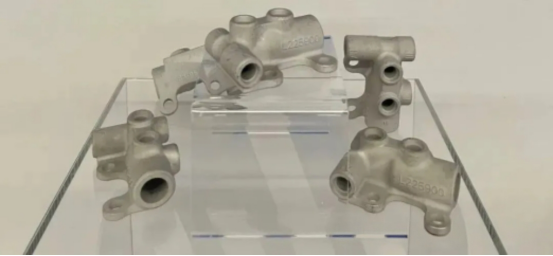

The design shown in Figure 1-3 was developed by Aidro, using 316L stainless steel, and was created for Fidema Group’s hydraulic cylinders for ships. The application of 3D printing technology reduced the number of hydraulic components that frequently leaked hydraulic oil, minimized the overall size, and optimized the design for the narrow available space. The layout of the cylinder control ports is customized according to the ship’s direction, rather than in a “linear” arrangement.

Thanks to design optimization, the weight was reduced from 3.8 kg for traditional components to just 0.63 kg.

With early momentum from Desktop Metal, binder jetting metal 3D printing technology has successfully been applied to hydraulic manifold production. HP later gained a late-mover advantage in this field.

Compared to laser-based 3D printing, binder jetting can achieve significantly lower manufacturing costs. At the 2024 TCT 3D Printing Show, exhibitors showcased innovative applications of this technology in the hydraulic manifold sector.