Titanium alloy 3D-printed hinge components produced by BLT have already been widely used in foldable smartphone hinges, and the company is now exploring their application in automotive door hinges. In the future, hinge structures across various scenarios may gradually adopt metal 3D printing technology.

As automotive design and manufacturing continue to evolve, user expectations for driving and riding experiences no longer focus solely on performance and basic configurations—they now extend to the quality and refinement of every detail of the vehicle. As a key component that affects the feel and long-term durability of door opening and closing, the design of the car door hinge must ensure reliable functionality while also balancing lightweight performance, strength, and aesthetic quality. This is essential for meeting users’ demand for enhanced tactile experience and overall perceived quality in vehicle craftsmanship.

Based on high-performance titanium alloy materials and combined with topology-optimized structural design, BLT has developed a titanium-alloy automotive door hinge that achieves lightweight, high strength, and excellent surface quality. The component was showcased at Formnext 2025 in Germany.

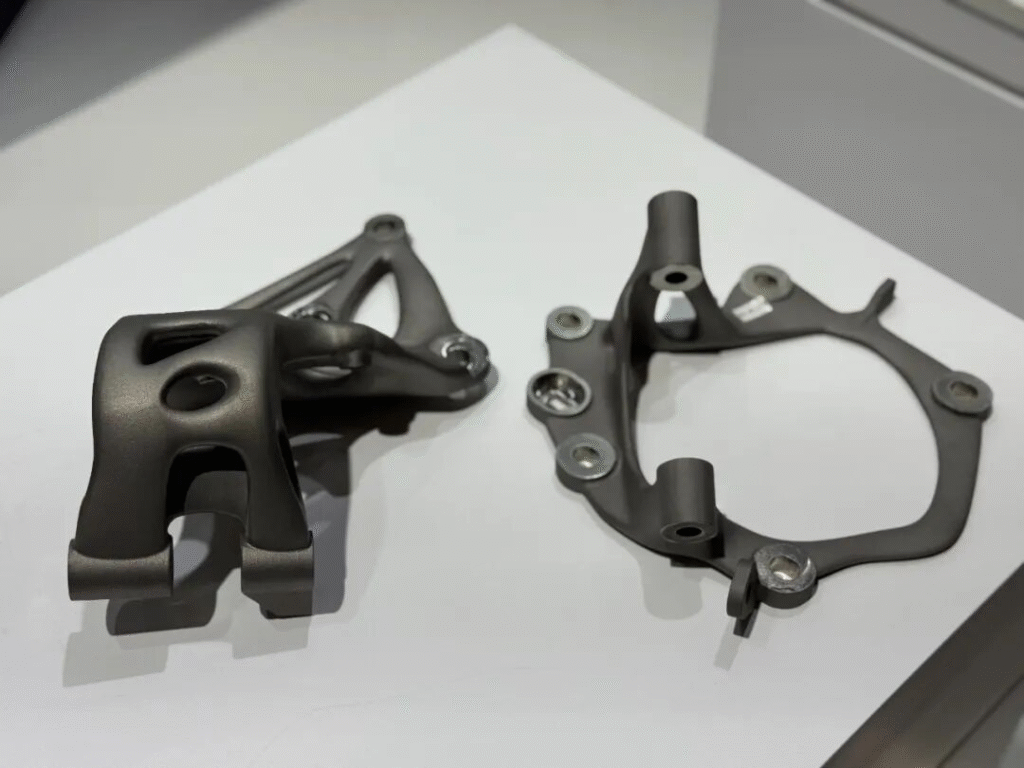

The door hinge consists of a leaf and a base plate, both manufactured using BLT-S-Ti64 titanium alloy powder. The leaf measures 263 mm × 207 mm × 132 mm and weighs approximately 2.43 kg; the base plate measures 247 mm × 242 mm × 117 mm and weighs about 1.02 kg.

Compared with similar parts traditionally produced using cast aluminum or cast iron processes, this titanium-alloy hinge achieves an overall weight reduction of around 50% while ensuring structural strength and operational reliability, providing strong support for component lightweighting and improved dynamic performance.

BLT’s titanium-alloy 3D-printed hinge components have already been widely adopted in foldable-screen smartphones, and the company is now exploring applications in automotive door hinges. Hinge structures used across various scenarios may progressively adopt metal additive manufacturing technologies in the future.

As automotive design and manufacturing continue to evolve, user expectations for the driving experience have expanded beyond power performance and basic configurations, reaching into the tactile quality and refinement of every detail of the vehicle. As a key component that determines the opening feel and long-term durability of car doors, hinge design must ensure reliable functionality while also achieving lightweight construction, high strength, and refined appearance — ultimately meeting consumer expectations for both detailed craftsmanship and overall vehicle quality.

BLT has developed a lightweight, high-strength, aesthetically refined titanium-alloy automotive door hinge by combining high-performance titanium-alloy materials with topology-optimized structural design. The hinge was showcased at Formnext 2025 in Germany.

The hinge assembly consists of a blade and a base, both manufactured using BLT-S-Ti64 titanium alloy powder.

– The blade measures 263 mm × 207 mm × 132 mm and weighs approximately 2.43 kg.

– The base measures 247 mm × 242 mm × 117 mm and weighs approximately 1.02 kg.

Compared with similar parts produced through traditional cast-aluminum or cast-iron processes, this titanium-alloy hinge achieves around 50% weight reduction without compromising structural strength or operational reliability—supporting component lightweighting and improved dynamic performance.

Titanium-Alloy Automotive Door Hinge Assembly

01 High-performance powder and intelligent equipment enable efficient hinge manufacturing

To meet the need for integrated fabrication of the hinge’s complex geometry, the product utilizes BLT’s self-developed BLT-S-Ti64 titanium-alloy powder. With precise composition control, excellent particle-size distribution, and high sphericity, the powder offers superior flowability, uniform recoating, and high printing accuracy. It is compatible with all BLT PBF-LB/M systems.

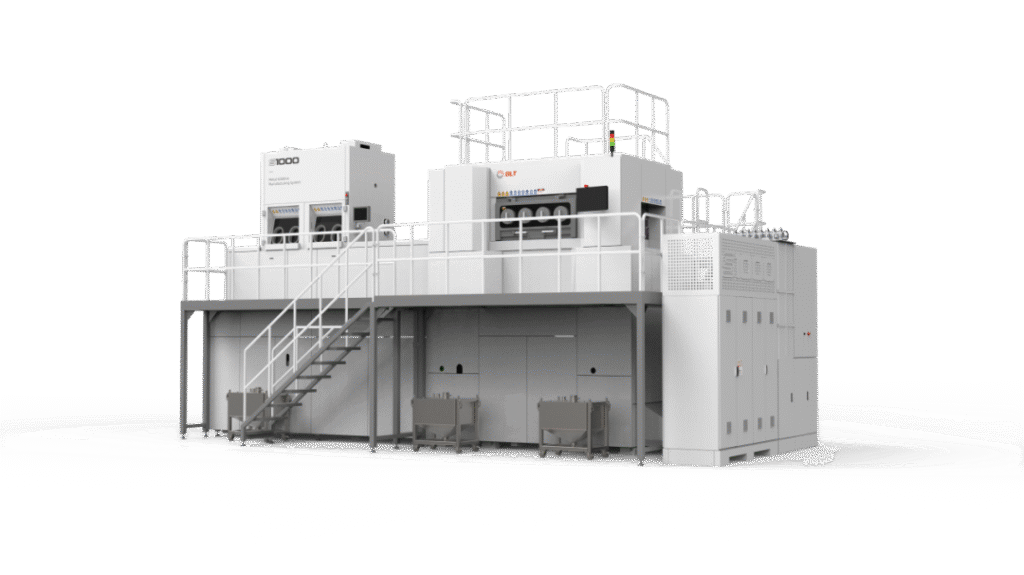

Built on this foundation, the BLT-S400 ensures stability and efficiency in hinge production. Equipped with the 1V4 powder-circulation system, a patented single-blade, bidirectional recoating technology, intelligent recoating strategies, an integrated calibration system, and an optimized airflow design, the S400 delivers efficient and reliable printing performance—meeting the requirements of mass production of automotive components.

02 Topology-optimized lightweight structure achieves the “light yet strong” performance goal

Based on real-world loading and operating conditions, the hinge design adopts topology-optimized internal structures. While satisfying requirements for strength, stiffness, and assembly precision, material distribution is refined and unnecessary mass is precisely removed—achieving an approximately 50% weight reduction.

This design significantly improves material efficiency and reduces unsprung mass. Meanwhile, the optimized structure maintains excellent mechanical strength and fatigue endurance, ensuring long-term durability and reliability. The hinge has already passed all required inspections and testing, meeting design standards and demonstrating readiness for mass production.

Metal additive manufacturing enables automotive components to break through traditional design limitations, achieving lighter, stronger, and more integrated manufacturing. Moving forward, BLT will continue expanding the application of metal AM technologies in the automotive sector, providing more efficient solutions for lightweight manufacturing.

BLT Metal 3D-Printed Body Components and Brake Calipers Support BYD Yangwang’s New World Records

On November 3, 2025, BLT announced that it collaborated with BYD on the Yangwang U9X’s 3D-printed body components and brake calipers.

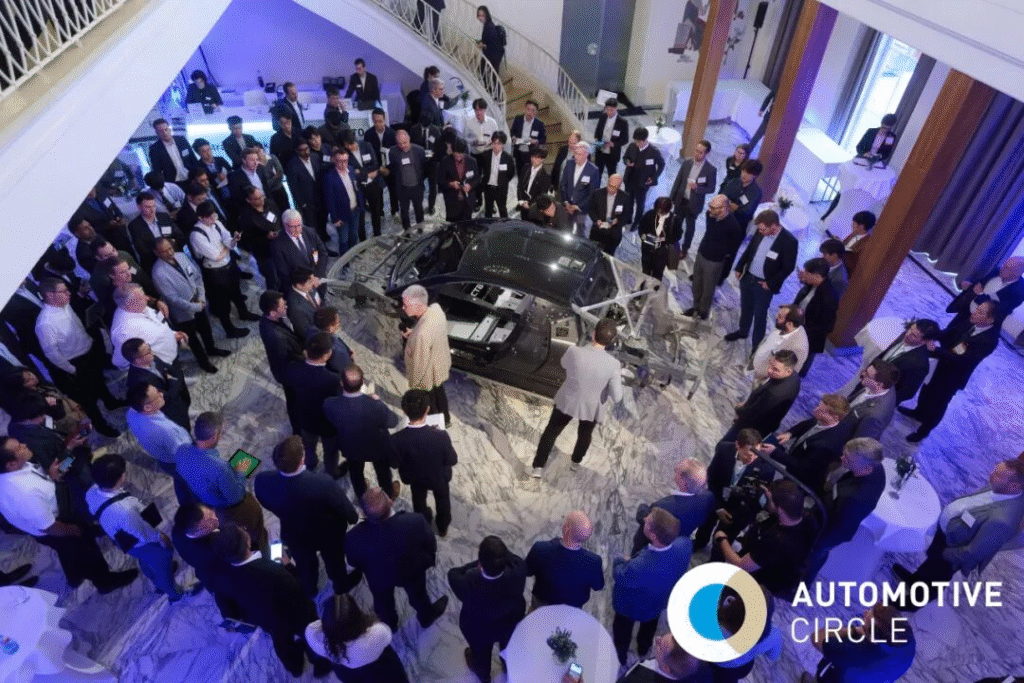

At the EuroCarBody 2025 conference (October 14–16), BYD showcased the world’s first integrated 3D-printed high-performance body for the Yangwang U9X. The vehicle immediately captured industry attention and received the highest expert-review score at the event.

Earlier, the Yangwang U9X underwent extensive performance development at Germany’s Nürburgring Nordschleife. At Germany’s ATP proving ground, it reached 496.22 km/h, breaking the world speed record for production vehicles. On October 21, Yangwang announced that the U9X achieved a 6′59″157 lap time at the Nürburgring Nordschleife, becoming the fastest production electric vehicle at the track—and the first supercar in the world to break both the top-speed and lap-time records simultaneously.

The development journey of the 3D-printed body structure of the Yangwang U9Xtreme (U9X) represents a “breakthrough exploration toward future manufacturing paradigms,” embodying the technological advances and innovative insights of the teams from BYD and BLT.

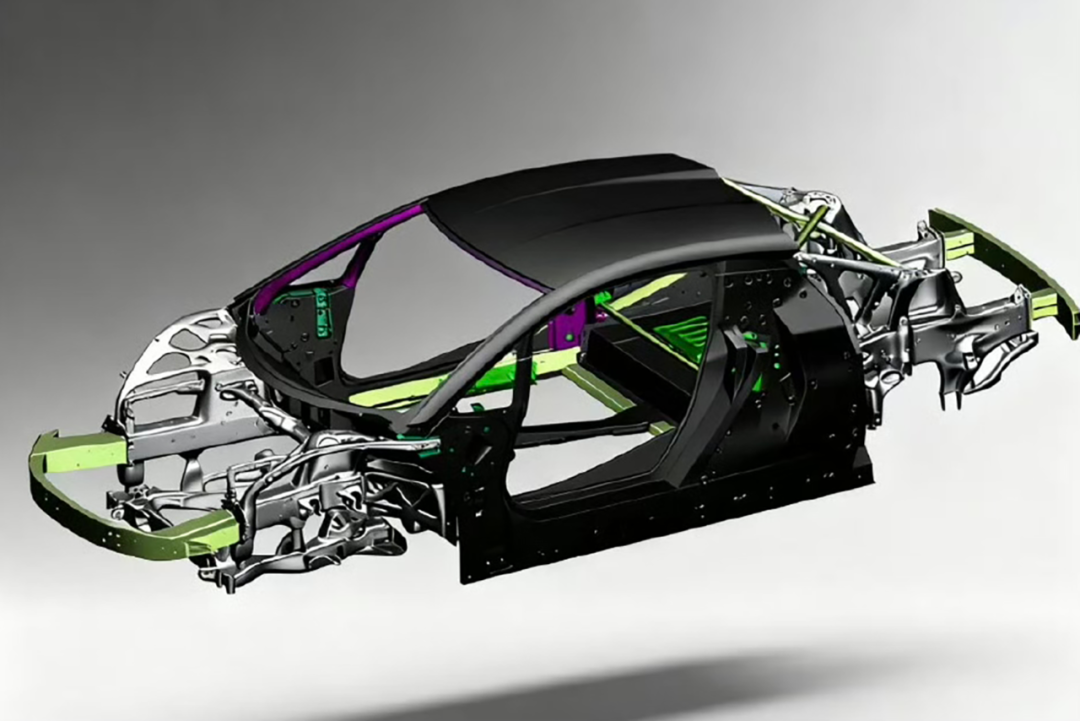

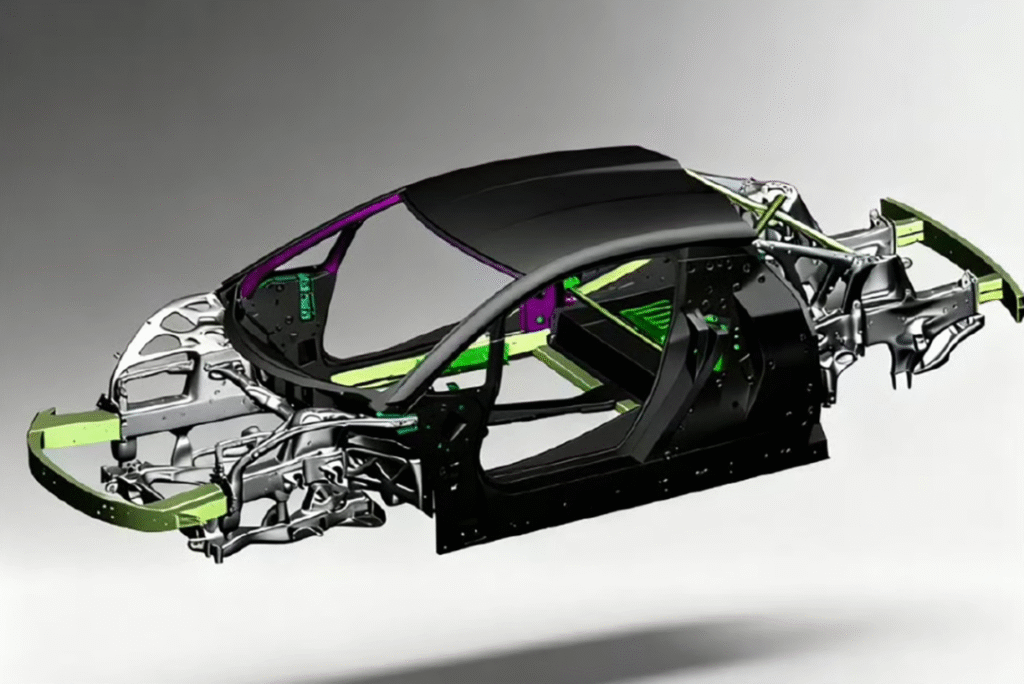

3D printing endows the vehicle body with a high level of design freedom and structural integration. Thanks to this technology, the body structure achieves both track-level stiffness and excellent crash safety, while also reaching an industry-leading level of lightweight performance.

BLT has accumulated many years of engineering experience in additive manufacturing of automotive components, offering a one-stop solution from structural optimization, part printing, post-processing, to inspection and testing. More than a decade of expertise in structural optimization, large-format 3D printing equipment, and formable high-strength aluminum alloy materials have together enabled the successful development and delivery of these components.

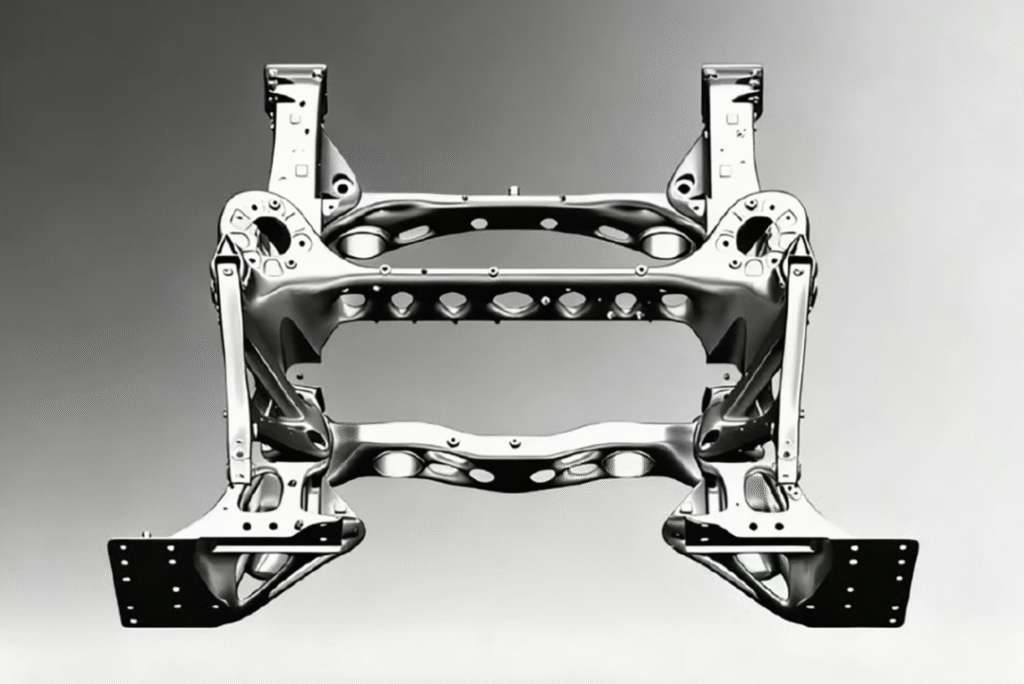

Lightweighting and high integration are the prominent technical features of the U9X body structure. Through topology-optimized design, using cavities and ribs to reinforce one another, the structure achieves over a 200% increase in torsional stiffness compared with a solid structure of the same mass. This allows mass and strength to be distributed as needed, laying a solid foundation for both safety and lightweighting.

The high-strength aluminum alloy body manufactured using BLT’s metal 3D printing technology reduces weight by more than 30% compared with traditional solutions.

Full Vehicle Body Structure Diagram

Body Component Structure Diagram

The vehicle body components are printed in an integrated manner using BLT-S1000, BLT-S615, and BLT-S815 systems, enabling rapid part delivery. In terms of printing accuracy, BLT’s large-format dimensional control technology ensures that more than 90% of the as-printed blank remains within a ±0.5 mm deviation range.

At present, BLT has over 200 large-format systems (with build volumes of 450 mm × 450 mm × 500 mm and above). With stable multi-machine coordination and a mature process framework, BLT ensures consistent performance across different machines and production batches, providing both the production capacity and quality assurance required for high-end component manufacturing.

Beyond the body structure, BLT has also delivered 20 sets of brake calipers for the Yangwang U9X, all of which have completed Nürburgring Nordschleife testing.

Based on the original design, the calipers were optimized through topology optimization, achieving a 20–30% weight reduction while integrating the oil channels and inserts into a single printed structure. This not only reduces assembly steps but also improves durability and reliability under extreme conditions.

The deformation of the calipers is currently controlled within ±0.5 mm, while the rear calipers are controlled within ±0.3 mm.

The parts achieve a density greater than 99.5%, with no defects detected under X-ray inspection.