The above section focused on metal heat exchangers — but must they necessarily be made of metal? The answer is no. On September 10, the well-known ceramic 3D printing technology developer Lithoz announced the development and production of a 3D-printed ceramic heat exchanger made from aluminum nitride (AlN), designed for use in megawatt-scale hydrogen-electric propulsion systems for aircraft.

The AlN ceramic heat exchanger is regarded as a key enabler for future hydrogen power systems. With its outstanding thermal conductivity, electrical insulation, and high-temperature resistance, AlN can maintain excellent heat transfer efficiency under extreme operating conditions. According to Lithoz, this technology will help the aviation industry reduce carbon emissions, improve system efficiency and sustainability, and at the same time cut maintenance costs and save hundreds of thousands of euros over the product’s lifecycle.

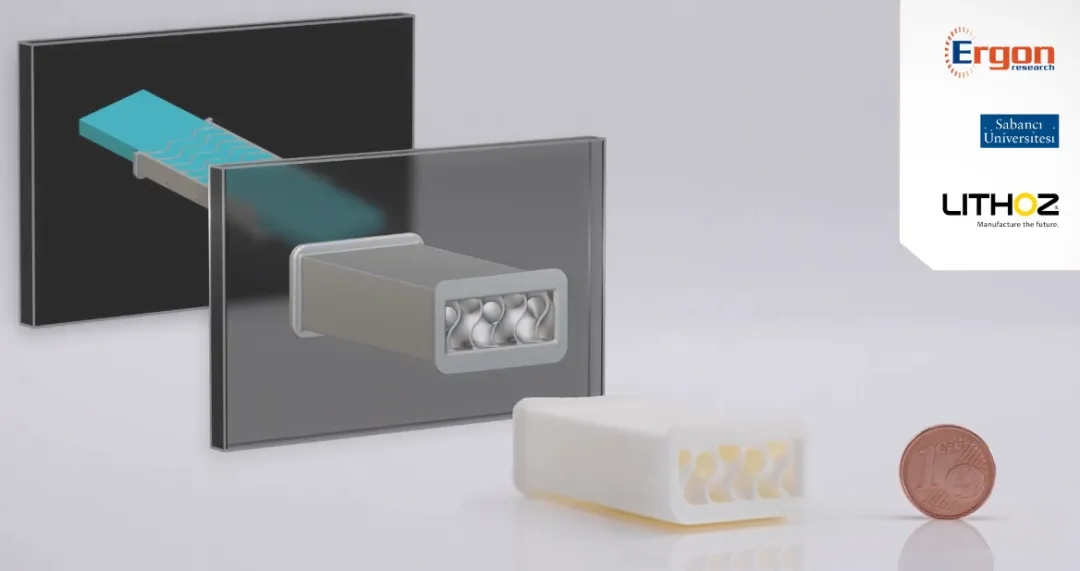

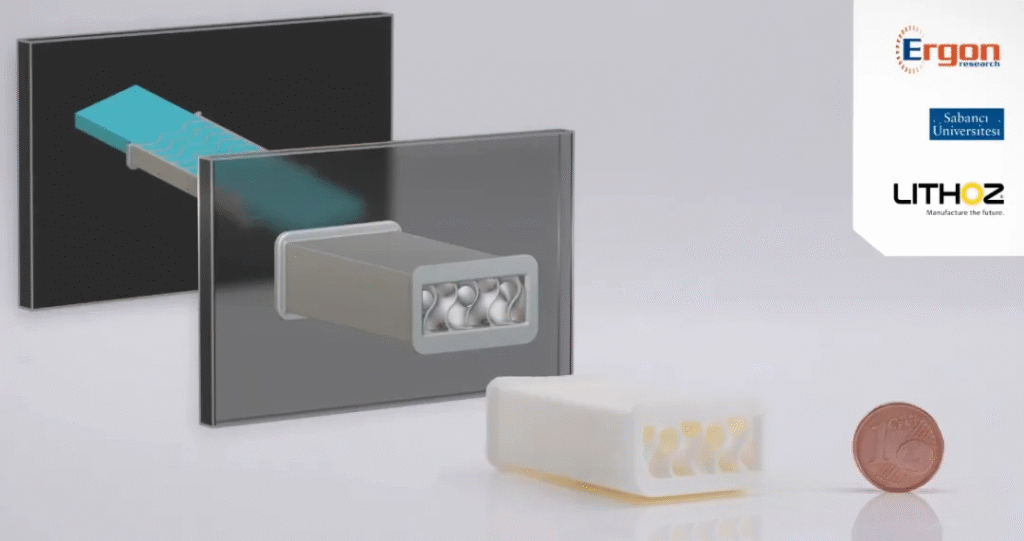

Innovative 3D Printed Aluminum Nitride Heat Exchanger by Lithoz

As part of the EU’s ambitious TRIATHLON project, Lithoz is contributing to the future of hydrogen-powered aerospace systems with its groundbreaking 3D printed aluminum nitride (AlN) ceramic heat exchanger. The project aims to replace traditional low-temperature hydrogen pumps with highly efficient, lightweight, and cost-effective ceramic solutions, paving the way for more sustainable and high-performance aerospace technologies.

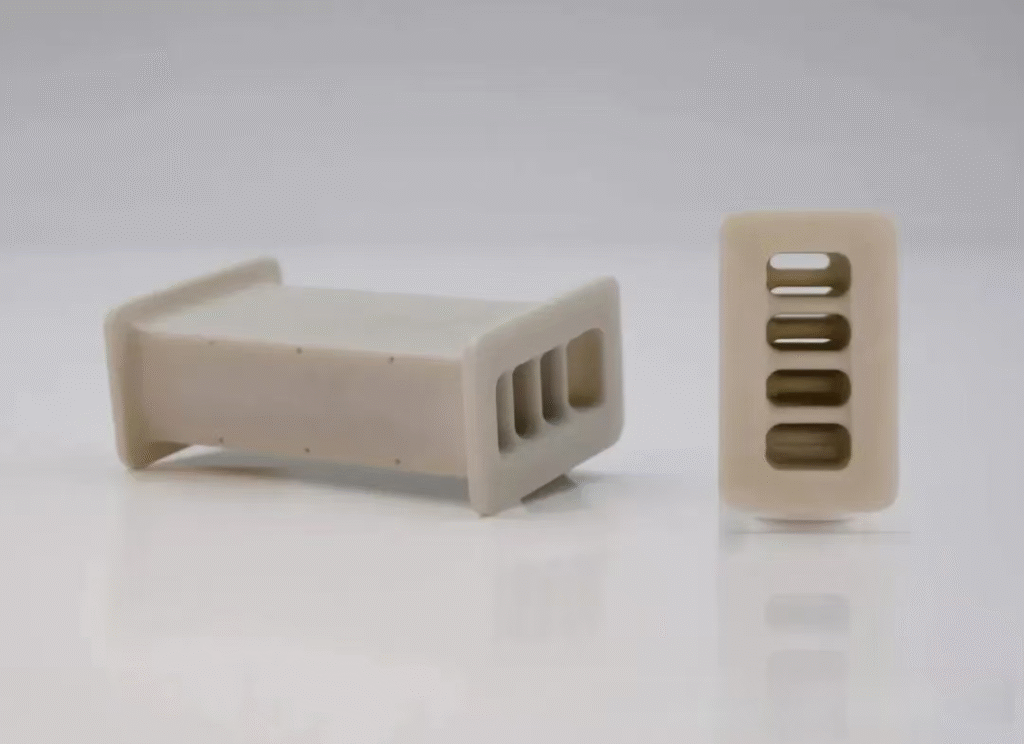

Designed by Ergon Research, this next-generation heat exchanger utilizes thermodynamically optimized control management to maximize energy transfer efficiency. The innovation is made possible through Lithoz’s LCM (Lithography-based Ceramic Manufacturing) technology, powered by the CeraFab System printer, which ensures exceptional precision, scalability, and material integrity.

This collaboration marks a significant step forward in applying advanced ceramic additive manufacturing to the aerospace industry, enhancing performance while driving down production costs and environmental impact.

Unlike traditional heat exchangers, the ceramic-based solution developed under the TRIATHLON project eliminates the need for energy-intensive cryogenic hydrogen pumps. Aluminum nitride (AlN), with its outstanding thermal expansion coefficient and high thermal conductivity, serves as an ideal material for addressing the thermal management challenges of these high-performance components. This enables the realization of a compact and lightweight system architecture, which is crucial for the electrification of aviation.

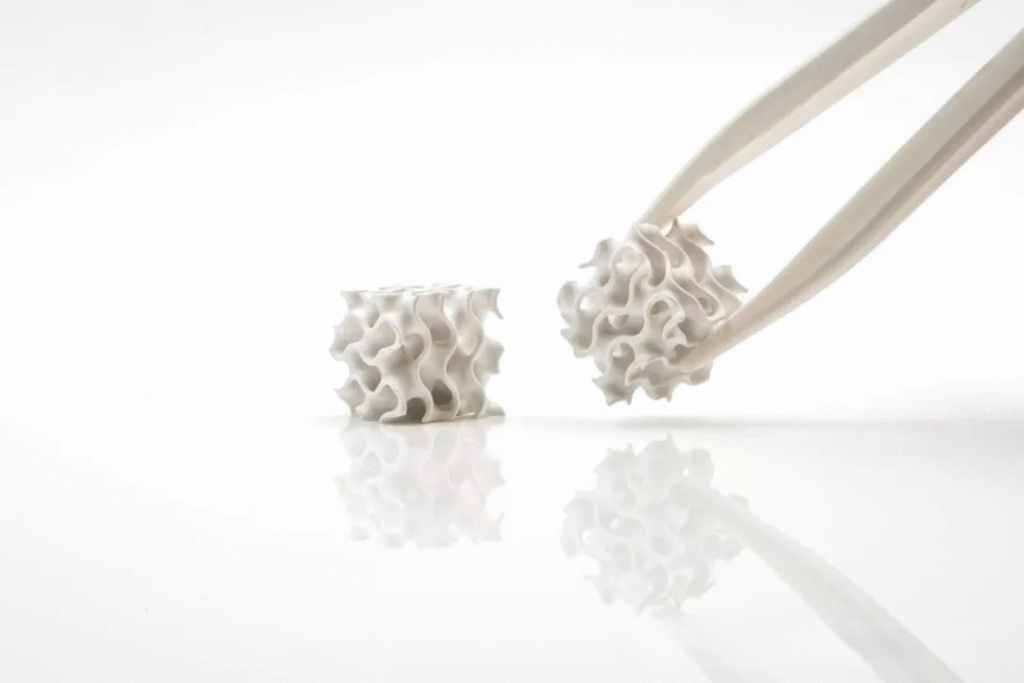

Lithoz’s AlN Ceramic 3D Printed Components

Lithoz’s advanced ceramics have already been validated in the aerospace industry and other high-stress sectors. Aluminum nitride (AlN) printed using LCM technology offers excellent thermal resistance and mechanical properties. Its stability in hydrogen environments below 600 °C enables high-precision, high-surface-area designs with outstanding thermal conductivity, ensuring maximum heat exchange within minimal space — a critical factor for next-generation hydrogen-electric systems.

Dr. Johannes Homa, CEO of Lithoz, commented on the project’s success so far:

“Achieving mass production of aluminum nitride represents a significant milestone for the aerospace industry. This material opens up design and application possibilities that are currently unattainable for other companies and will make a decisive contribution to a greener future for aviation.”

It is reported that the Airbus ZEROe aircraft will be equipped with an electric propeller propulsion system powered by hydrogen fuel cells, which convert hydrogen into electricity through chemical reactions. The only byproduct of this process is water, meaning that as long as the hydrogen is produced using renewable energy sources, the entire process is virtually carbon-neutral. The aircraft will feature four propellers, each driven by its own fuel cell stack.