Chinese 3D Printer Manufacturer Bambu Lab Technology Officially Launches Local Print Farm Management System After Nearly a Year of Beta Testing

After nearly a year of public testing, Chinese 3D printer manufacturer Bambu Lab Technology has officially launched its local network management tool — the Bambu Lab Print Farm Management System.

This new software is designed for users managing multiple 3D printers, enabling full control of an entire printer fleet without the need for cloud connectivity. The platform, which was made available for free download on May 27, 2025, currently supports the P1, A1, and X1C series 3D printers, with support for the X1E and H2D models expected to be added later this year.

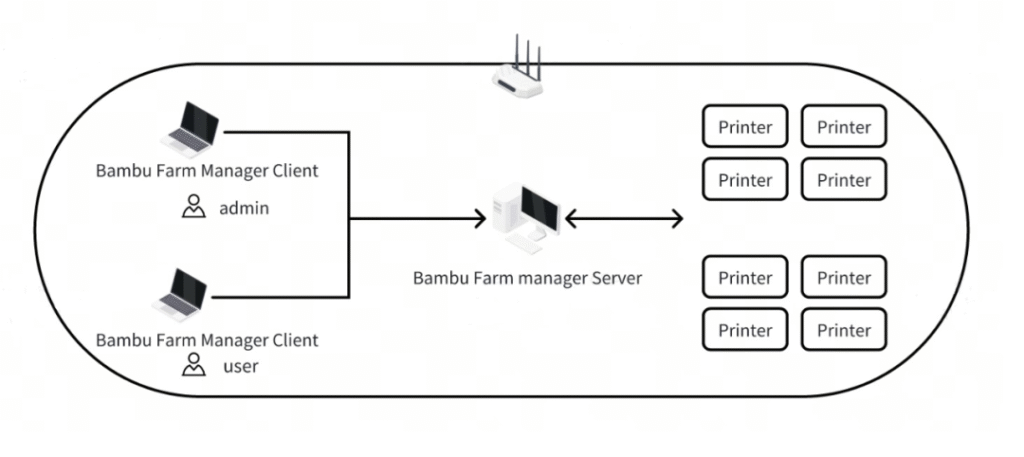

The Bambu Lab Print Farm Management System is built to address the growing concerns around data privacy and operational efficiency. It allows users to directly monitor and control their printers through a local network. Its target audience includes print farms, educational institutions, businesses, and other organizations with strict IT requirements. The tool features a server component that runs in the background 24/7 to maintain communication with the printers, as well as a client interface that enables users to manage print jobs.

“The Print Farm Management System allows me and my clients to have complete control over the flow of their data. It also makes managing printer fleets much easier, significantly reducing operational costs,” said Korneel, Engineer and Founder of Korneel’s 3D Services.

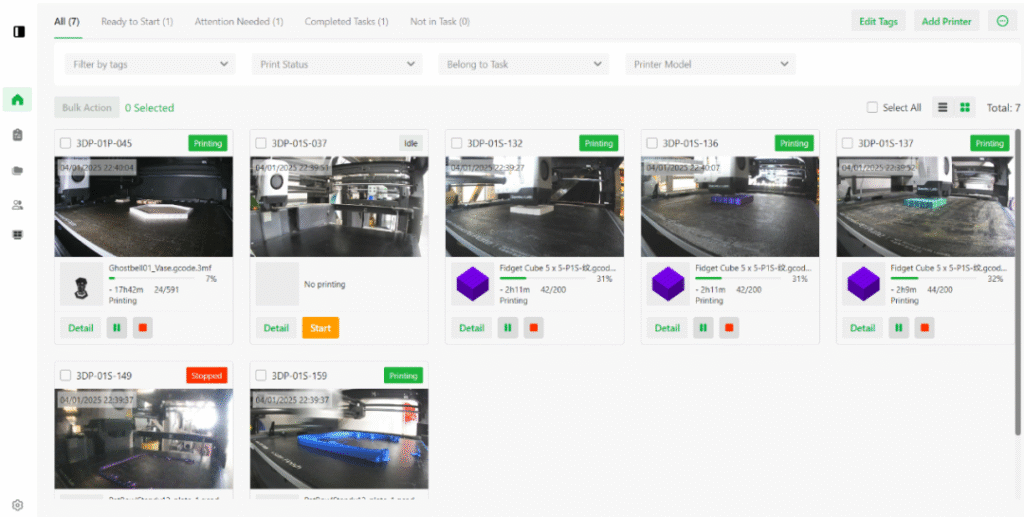

Real-Time Monitoring Feature of Bambu Lab Technology’s Print Farm Management System

Key Features of Bambu Lab Technology’s Print Farm Management System: Real-Time Monitoring, Batch Control, and More

The Bambu Lab Print Farm Management System offers a variety of essential features, including real-time monitoring, batch control, an intelligent task queue based on device availability, file organization tools, and power management options for staggered printer startups. These features are specifically designed to meet the demands of large-scale printer fleets, with the only limiting factors being the user’s local network and system resources. The Chinese manufacturer emphasizes that all currently available features are free to use, although there may be paid enhancements in the future.

For Korneel, the software has already proven to be effective. As the founder managing about 35 Bambu Lab Technology 3D printers, his fleet can scale up to 45 printers as project demands increase. His clients range from manufacturers to artists, many of whom have strict compliance requirements concerning privacy, data handling, and frameworks like GDPR.

Before adopting the Bambu Lab Print Farm Management System, Korneel relied on cloud-based tools, which raised concerns about data storage, deletion, and telemetry. Faced with growing client demands for guarantees that design files and print data remained entirely local, Korneel felt immense pressure. The Bambu Lab Print Farm Management System’s local deployment eliminated dependence on the cloud, enabling him to maintain full control over client files and system operations, resolving these concerns.

The system allows Korneel to streamline workflows while ensuring security. He can manage printers across network segments, monitor job progress via a unified dashboard, and guarantee that data never leaves his physical premises. This setup also supports quick scalability, allowing him to add or remove machines with minimal resistance based on project needs.

Korneel highlights that hardware performance also plays a crucial role. Faster print speeds and consistent output quality help him meet deadlines and reduce rework, while low energy consumption and minimal maintenance contribute to overall cost-effectiveness. After completing thousands of print jobs, his device cluster has remained stable. While one machine did require technical support, Bambu Lab Technology responded appropriately, though the exact nature of the issue was not disclosed.

File Organization Feature of Bambu Lab Print Farm Management System

3D Printing Management Tools Enhance Efficiency and Control in Print Farms

In the field of 3D printing, print management tools play a crucial role in remote monitoring, controlling, and optimizing multiple print jobs, all of which are essential for boosting efficiency and reducing downtime. These tools are especially beneficial for print farms, where central coordination of equipment and users is indispensable.

At the 2021 RAPID+TCT exhibition, Markforged, which was acquired by Nano Dimension, launched Eiger Fleet, a cloud-based print management platform designed to help manufacturers scale their 3D printing operations. The software was developed to seamlessly integrate with existing workflows, enabling users to automate and monitor their entire 3D printer fleet while maintaining strict control over data, quality, and access.

Through real-time tracking, API integration, and role-based access management, teams can manage digital inventories, allocate tasks, and streamline production processes from a single interface. Early adopters such as Vestas Wind Systems have leveraged Eiger Fleet to reduce the cost and delivery cycle of turbine tools, cutting a three-week process down to just three days.

Meanwhile, Polish 3D printer manufacturer Zortrax introduced its inCloud Print Management System, aimed at simplifying the remote operation of its 3D printers, especially for businesses managing large print farms. The platform allows users to upload models, remotely start or pause prints, and coordinate simultaneous tasks with its Multiprint feature.

Designed for team environments, inCloud enables user groups to be assigned to specific printers, reducing the need for on-site supervision. To protect user confidentiality, files are encrypted during transmission and deleted after uploading. Storage plans range from 1GB to 50GB, with monthly renewals available.

Bambu Lab Print Farm Management System: Server and Client Components