Mass production through 3D printing is already underway. Around the world, many companies have deployed dozens, hundreds, or even thousands of metal 3D printers to mass-produce parts. However, ceramics, which is also a widely used material, has yet to see more than a hundred industrial-grade ceramic 3D printers being used for production globally.

In the global manufacturing industry’s accelerating shift towards sustainability and intelligence, precision ceramic additive manufacturing is becoming a key engine for the sustainable development of high-end manufacturing, thanks to its unparalleled advantages in design freedom, material utilization, and precision. After more than 30 years of technological accumulation, ceramic additive manufacturing has moved beyond the laboratory, demonstrating immense potential in cutting-edge fields such as aerospace, healthcare, automotive, energy, and semiconductors. However, as the industry approaches the threshold of mass production, the bottleneck of scaling up remains a core challenge. So, how can this be overcome? Building a collaborative innovation ecosystem is the key answer.

Pain Point: The Island Effect Hindering Mass Production

Currently, the fragmented state of the ceramic additive manufacturing industry chain—where “technology service providers, equipment manufacturers, and end-users each operate independently”—has created a significant “island effect,” which is the biggest obstacle to the large-scale implementation of technology. Fragmented resources and information are insufficient to support the stable, efficient, and cost-effective mass production demands.

Solution: Building a Collaborative Innovation Ecosystem

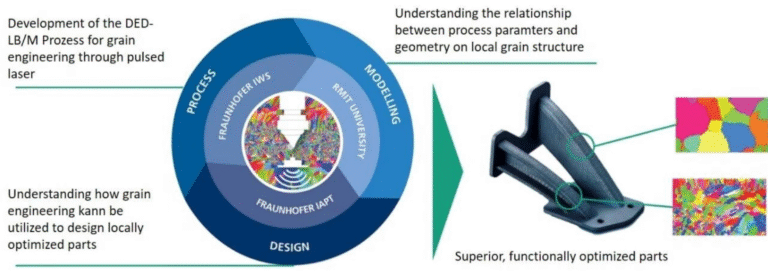

The key to breaking through this bottleneck is to break away from conventional thinking and build a deeply integrated 3D collaborative innovation system:

Vertical Integration: Achieving seamless connection across the entire process from “material development, process optimization, equipment matching, to application verification,” ensuring efficient operation of the technology chain.

Horizontal Integration: Promoting cross-industry knowledge sharing and technology transfer, leveraging collaborative innovation to meet increasingly complex functional integration design demands.

Standards Co-building: Establishing unified industry standards, certification systems, and quality assurance standards to lay the foundation for efficient resource utilization and market trust.

Leveraging ISO 9001 Quality System Certification, 3D printed ceramics not only provide customers with comprehensive professional services covering the entire process of “design optimization, material selection, and functional realization,” but also ensure the high performance, precision, and consistency of surface quality between batches through rigorous quality control — this is the lifeline for large-scale applications.

Innovation Beyond Technology: Empowering the Industry through Resource Collaboration

Currently, 3D printed ceramics have successfully moved from sample development to mass additive manufacturing in fields such as aerospace, semiconductors, healthcare, industrial applications, and energy. These successful applications have fully validated the process advantages and brought continuous value enhancement to end products. Core Technological Advantages:

A broad library of oxide/non-oxide ceramic materials

A mature database of ceramic printing process parameters

Globally validated successful examples and a full-process quality control system

Best practice case

Medical – Quadrupole Probe Head: Integrated internal complex curved channels and electrical functions, combined with selective metal coating, balancing the needs for conductivity and surface smoothness.

Semiconductor – Wafer Transfer Suction Cup: Integrally formed to manufacture internal precision gas channels, while meeting the stringent requirements for ultra-high sealing, high temperature resistance, corrosion resistance, and cleanliness.

Consumer Electronics – Ceramic Exterior Parts: Achieving insulation, scratch resistance, wear resistance, and lightweight hollow design, giving the product a unique design aesthetic and high-end ceramic texture.

Industrial & Energy – Corrosion-Resistant Gas Nozzle: Integrated with 62 precision honeycomb gas holes to ensure uniform gas distribution, perfectly handling high temperatures, corrosive environments, and complex curved channel challenges.

Already Launched Ceramic 3D Printing Services to the Global Market

In the future, with the increasing global demand for smart manufacturing, precision ceramic additive manufacturing technology will play a greater role in reducing material waste, optimizing production processes, and lowering carbon emissions.