Researchers Develop Plant-Based 3D Printing Resin, Advancing Sustainable Photopolymerization Technology

On May 7, 2025, a team from the Polytechnic University of Catalonia (UPC) and the Catalan Institute of Chemical Research developed a polymer resin derived from plant-based materials, reducing the reliance of 3D printing on fossil fuel-based resins. The research findings were published in the RSC journal Polymer Applications under the title “Synthesis of bio-sourced liquid resins and their photopolymerization with poly(ethylene glycol) diacrylate in the roadmap to more sustainable digital light processing technologies.”

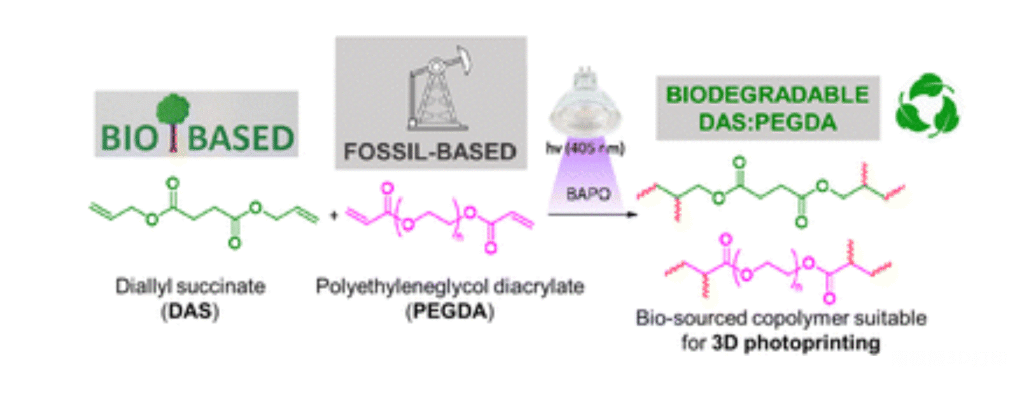

Researchers from the Polytechnic University of Catalonia (UPC) and the Catalan Institute of Chemical Research (ICIQ) developed a new type of 3D polymer resin using monomers sourced from various natural origins, including succinic acid—a compound found in foods such as corn and broccoli. In light-based 3D printing, the resin needs to be liquid, solvent-free, and have fast polymerization kinetics to ensure industrial feasibility.

This research, led by UPC, was conducted in two phases. In the first phase, plant-based materials were used to prepare polymer resins, with the process developed in collaboration with the Materials and Molecular Engineering Innovation—Regenerative Therapy Biomaterials (IMEM-BRT) group and Elaine Armelin, a professor at the Barcelona Eastern Engineering School (EEBE). In the second phase, under the guidance of researcher Fernando Bravo, the knowledge and technology transfer (ICIQ-KTT) and industrial projects department at ICIQ printed the resin. This research is crucial for promoting more sustainable 3D printing technologies.

The polymer resin developed by the UPC and ICIQ teams is sourced from natural materials—succinic acid, malic acid, and tartaric acid—and can be converted into functional resins through a single-step synthesis.

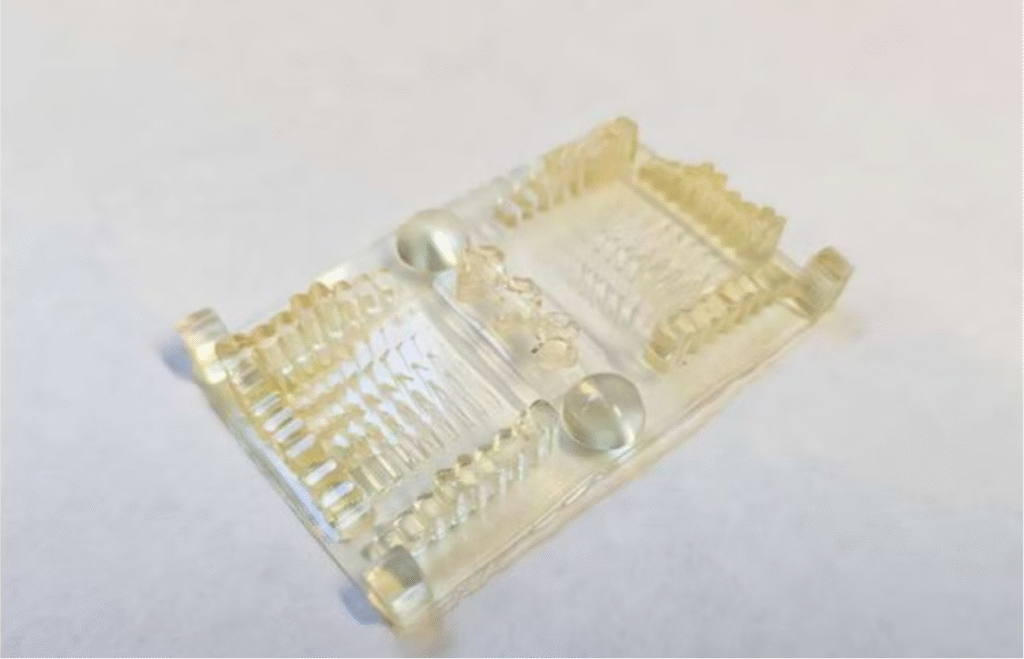

The results of the study show that by combining 50 wt% bio-based succinic acid diacrylate with 50 wt% polyethylene glycol diacrylate (a petroleum-based copolymer known for its fast UV reaction), a bio-sourced liquid resin with excellent thermal stability is obtained. This resin can be used in Digital Light Processing (DLP) or Stereolithography (SLA) 3D printers. The DLP-printed samples, after photopolymerization, exhibited excellent dimensional resolution and transparency. Most importantly, the samples quickly undergo hydrolytic degradation due to the ester bonds introduced from the natural monomers.

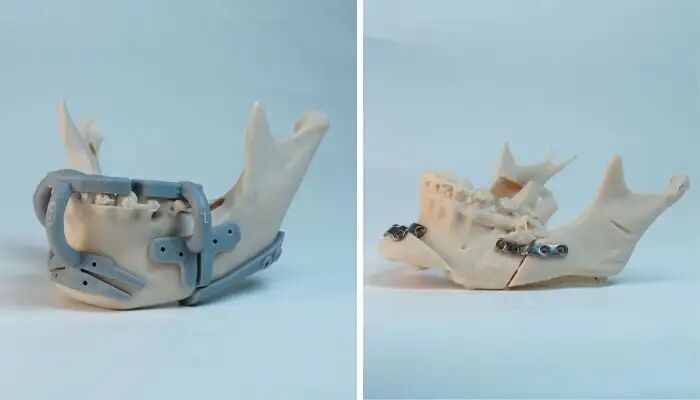

This work is part of the Base-3D project, which is led by CIM UPC. The project aims to advance the maturity of additive manufacturing technologies and promote their application in Catalonia’s industries, operating rooms, businesses, and classrooms, thus driving the development of additive manufacturing technologies. This is the second polymer resin developed by ICIQ and UPC through the Base-3D project, part of the Light3D cluster led by LEITAT Technology Center (project BASE3D: 001-P-001646). The first resin is a biodegradable polymer that performs excellently in DLP printing.

Currently, the IMEM-BRT group is also investigating soft bio-based polymers such as alginates, chitosan, and gelatin as sustainable superabsorbent materials for applications in soil, batteries, and seawater desalination cells’ polyelectrolytes.