Researchers from City University of Hong Kong, MIT, and several other institutions have developed a new type of mechanical metamaterial structure by integrating high-precision 3D-printing, medium-entropy alloy materials, and structural topology optimization. This structure is the first to achieve energy-absorption performance in a bulk (macroscale) material that approaches that of nanoscale materials.

In other words, this material can effectively resist penetration by stainless-steel projectiles traveling at initial velocities of up to 900 m/s.

Such a level of protective capability can already address threats posed by most light weapons (excluding high-velocity armor-piercing rounds). Therefore, it offers a new solution for developing protective structures in defense, aerospace, and vehicle safety applications.

Material Selection

For material selection, the research team chose a CoCrNi medium-entropy alloy. When subjected to impact, this material readily activates a series of self-protective mechanisms. The impact energy sequentially induces deformation twinning, crystal structure transformation, and the formation of nano-scale amorphous shear bands within the material. These microstructural evolutions dissipate the impact energy, thereby providing excellent impact resistance. As a result, CoCrNi alloys are regarded as one of the metal systems with the best combined performance in strength, ductility, and fracture toughness.

Structural Design

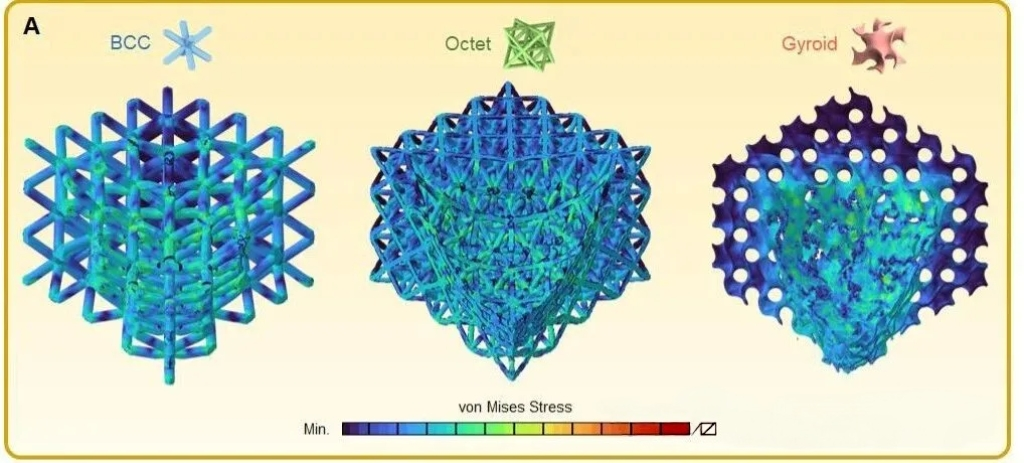

Another key factor influencing impact resistance is structural design. In this study, the authors designed three architectures: a body-centered cubic (BCC) lattice structure, an octet lattice structure, and a Gyroid shell structure formed by a triply periodic minimal surface (TPMS) lattice. The first two are essentially rod-based architectures, whereas the third is composed of continuous curved shell surfaces.

High-precision Manufacturing Process

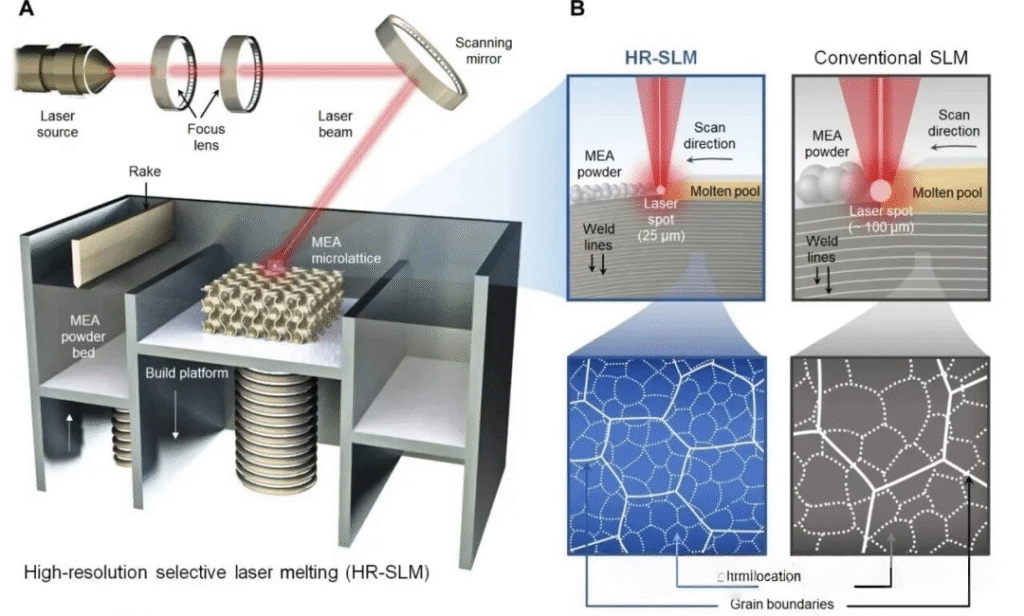

In terms of manufacturing, the researchers employed a high-resolution laser powder bed fusion 3D printing technology (HR-SLM). The laser spot size is only 25 μm, and the powder feedstock has particle sizes controlled between 5 and 25 μm. During printing, each powder layer is spread at a thickness of 10 μm.

According to the research team, this process combination promotes further grain refinement and the formation of a denser dislocation cell network. Such refined microstructures have previously been shown to significantly enhance material strength without compromising ductility.

Left: Schematic diagram of the HR-SLM system used for manufacturing micro-lattices.

Right: Differences between the HR-SLM system and conventional commercial SLM systems in terms of printing configuration and microstructure (particularly the density of dislocation cells).

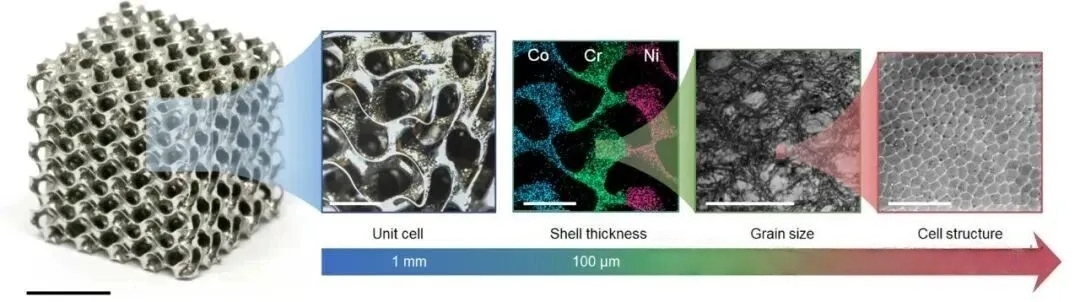

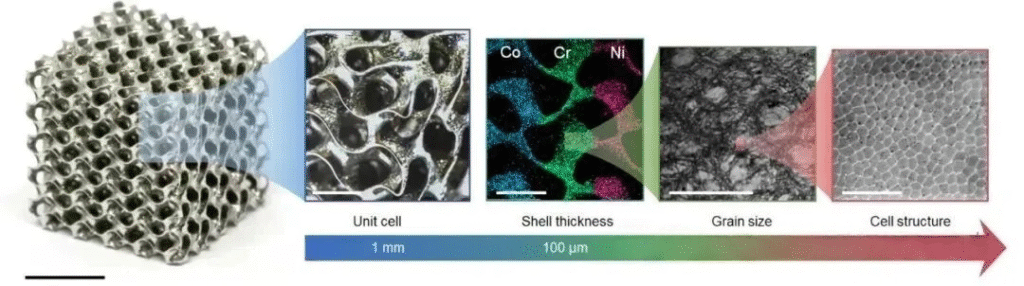

Hierarchical Structure of Micro-Lattices and Microstructural Differences Before and After Deformation

From the hierarchical architecture of the micro-lattice, the thickness of the gyroid micro-lattice shell is less than 100 µm. Its geometry overlaps with the energy-dispersive X-ray spectroscopy (EDS) mapping. Using the quality map obtained from electron backscatter diffraction (EBSD), one can clearly observe the alloy’s grain boundaries as well as the nanoscale dislocation cell networks generated by the HR-SLM process.

TPMS Lattices Exhibit Superior Impact Resistance

Quasi-static in-situ uniaxial compression tests on the micro-lattices show that the TPMS gyroid lattice not only possesses excellent mechanical properties, but its modulus and strength are more than four times higher than those of the BCC lattice. Furthermore, its stress–strain curve is smoother than that of the Octet truss, without post-yield softening, resulting in more than twice the specific energy absorption.

It should be noted that shell-type micro-lattices exhibit significantly improved mechanical performance compared with truss-type micro-lattices—an ideal combination of structural design and material selection. If titanium alloys were used instead, numerous fractures and pronounced shear bands would appear on the shell structure.

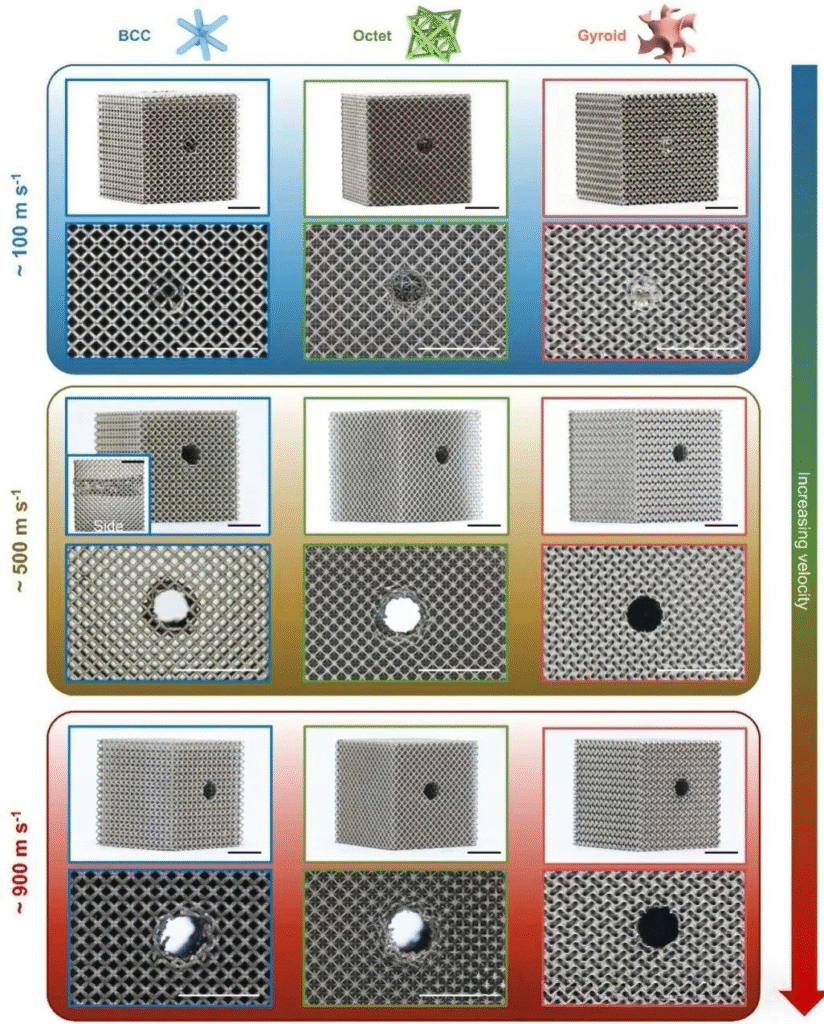

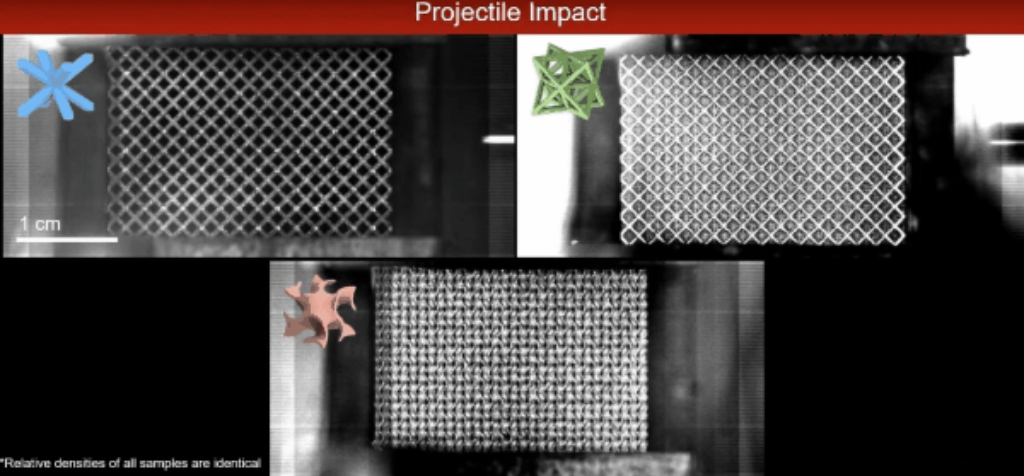

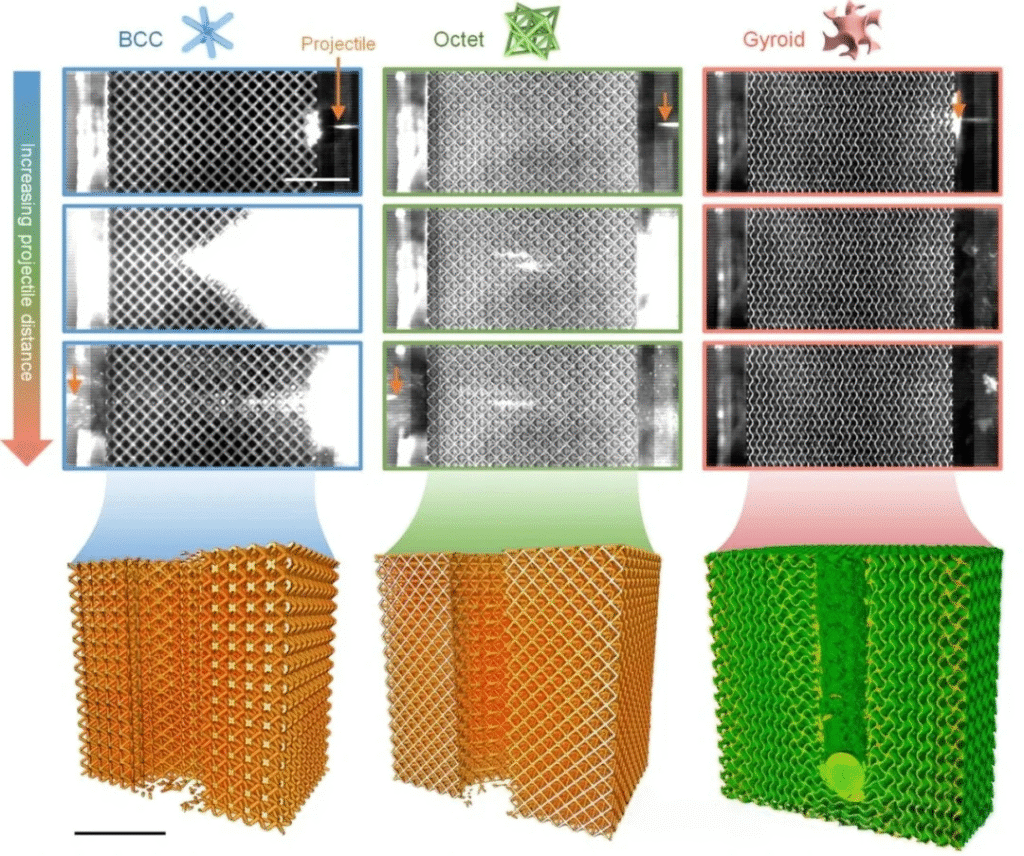

High-Velocity Impact Testing of the Three Lattice Structures

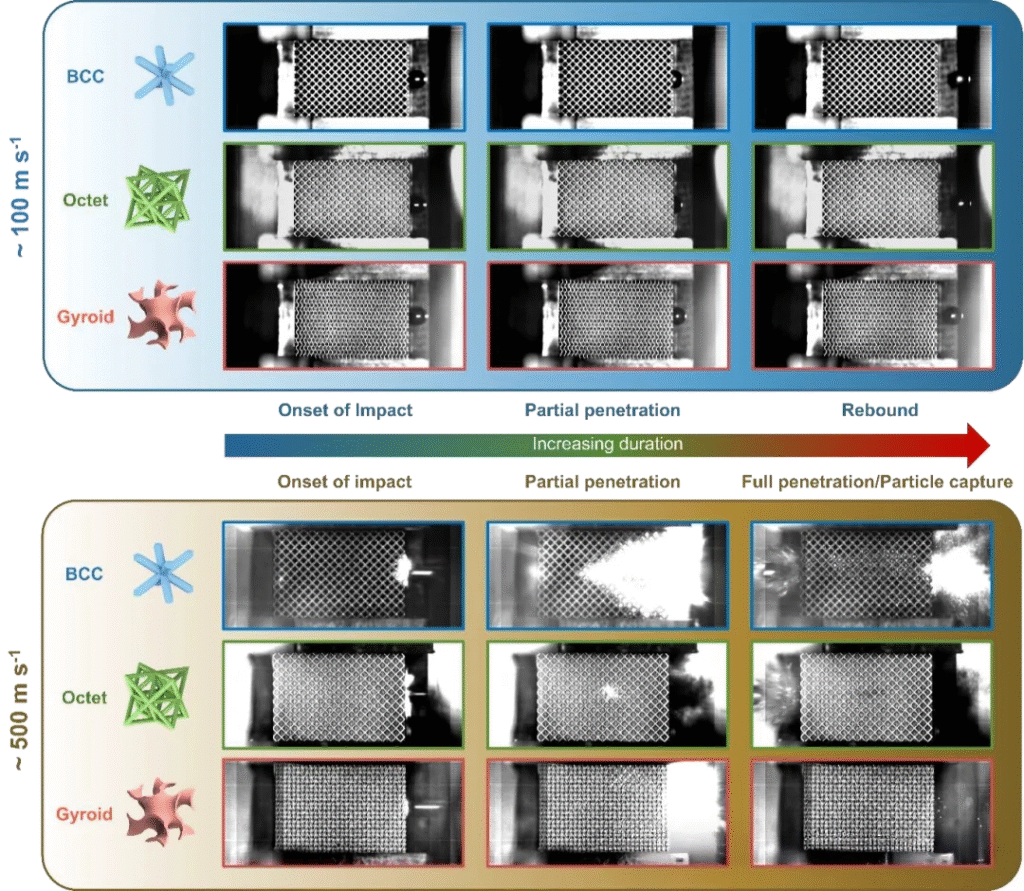

To investigate the extreme impact resistance of the lattice materials manufactured via HR-SLM, the researchers conducted a series of in-situ projectile impact tests, with projectile velocities ranging from 100 m/s to 1500 m/s.

The experimental setup involved accelerating stainless-steel spheres using an air gun, while a high-speed camera captured the impact process. Small projectiles traveling at speeds exceeding 500 m/s penetrated completely through both the BCC lattice and the octet lattice. In contrast, the gyroid TPMS lattice successfully stopped the projectile; even when the projectile velocity exceeded 900 m/s, it still failed to fully penetrate the structure.

It should be noted, however, that the study did not explicitly specify the dimensions of the impact-tested samples. Based on an approximate size comparison between the projectile and the test specimens, the overall thickness of the lattice samples is estimated to be around 30 mm.

The researchers also investigated the influence of projectile size. When the projectile diameter increased from 5 mm to 10 mm and its velocity was approximately 900 m/s, the BCC lattice outperformed the octet lattice in terms of non-ballistic energy absorption. This is because the BCC lattice has a significantly larger contact area and greater plastic dissipation within the densified zone. At higher velocities, the octet lattice had previously shown slightly better performance than the 5 mm projectile impacting the BCC lattice due to stronger dynamic stress effects. However, with the larger projectile size, compaction became the dominant factor.

Specifically, when the projectile diameter is equal to or greater than five unit cells, compaction governs the response, whereas for smaller projectiles, inertial effects become more prominent. The gyroid lattice, thanks to its advantages in both compaction behavior and induced dynamic stress, outperformed the strut-based lattices across all conditions.