Wolf 3D Technologies is a well-known 3D printing service provider in India. The company’s transformation trajectory is a microcosm of the broader paradigm shift in manufacturing. As an Indian company focused on additive manufacturing and design, Wolf initially adopted FDM technology due to its cost advantages. However, when addressing high-end sectors such as aerospace and automotive, FDM’s limitations became apparent — aerospace demands micron-level tolerances for components, while the automotive industry increasingly requires high-performance, lightweight solutions. These industry requirements highlighted the need for Wolf’s technological upgrade, illustrating how paradigm shifts in manufacturing are reflected in the challenges faced by companies.

This is especially evident in the application of carbon fiber composites. Today, the aerospace industry urgently seeks lightweight and structurally optimized materials to improve fuel efficiency and reduce operational costs. Similarly, the automotive sector continuously explores better material solutions to enhance power performance and reduce energy consumption. Carbon fiber, with its high strength-to-weight ratio, fatigue resistance, and corrosion resistance, has become a strategic material in modern industrial design. Furthermore, advances in technology, expanded production capacity, and reduced costs are expected to drive carbon fiber into emerging markets such as low-altitude aircraft and robotics, positioning it as a key force in the next stage of material innovation.

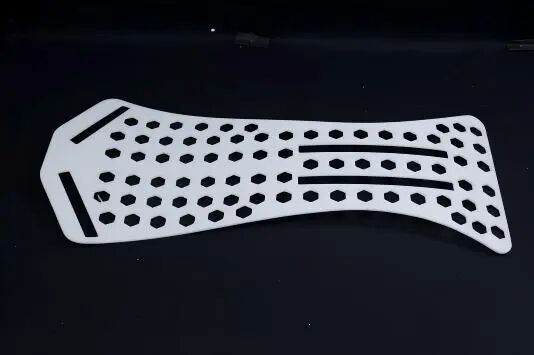

In manufacturing carbon fiber components, the master mold is critical. As the foundation for composite molds, the precision and surface finish of the master mold directly impact the appearance and performance of the final product. Previously, Wolf 3D attempted to use FDM (Fused Deposition Modeling) to produce master molds, but two major issues arose in practice:

Surface layer patterns in FDM prints are prominent, requiring extensive manual sanding and filling. This post-processing is not only time-consuming and labor-intensive but also difficult to standardize, significantly affecting production efficiency and product quality.

High surface roughness of FDM molds makes it impossible to meet the strict surface finish requirements demanded by carbon fiber layup processes.

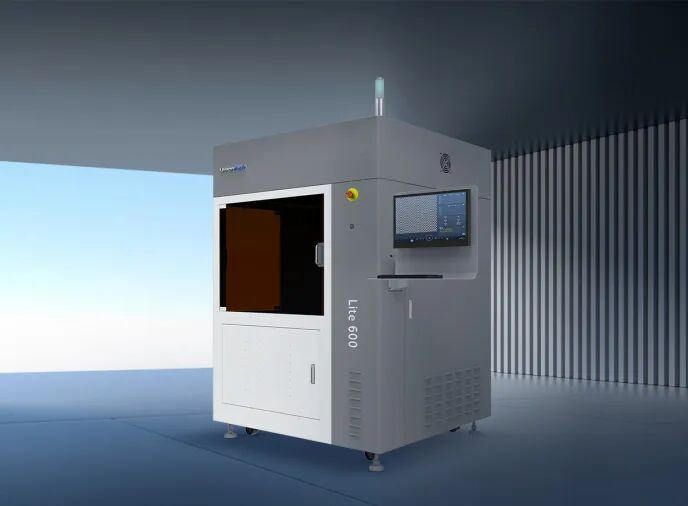

When Wolf integrated the UnionTech Lite 600 SLA photopolymer 3D printer into its production system, a revolution in manufacturing and process capability began. Mudassar, Wolf 3D’s Chief Technology Officer, noted that UnionTech was chosen among many SLA 3D printing brands for its industrial-grade stability, batch production-ready specifications, and comprehensive localized support. For service-oriented companies like Wolf, equipment must not only be powerful but also user-friendly, reliable, and easy to maintain. The Lite 600 perfectly balances performance and reliability, making it an attractive choice in Wolf’s transition from FDM to SLA technology.

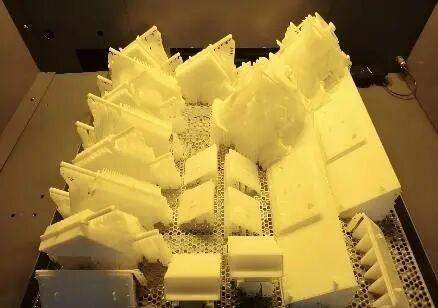

“Since the introduction of the Lite 600, our production efficiency has improved significantly. Previously, producing a single model took nearly 10 hours. Overall efficiency has increased by almost 60%, and the production cycle has been reduced from several days to just a few hours. This successfully marks our technological upgrade from FDM to SLA and has also driven business growth. We expect a nearly 16-fold increase in 2024–2025 compared to 2023, with SLA technology continuously fueling our rapid business expansion,” said Mudassar.

“At the same time, with our business growing rapidly, expanding our SLA printing capacity will be our next key step, ensuring that we can continue to deliver high-quality products efficiently.”

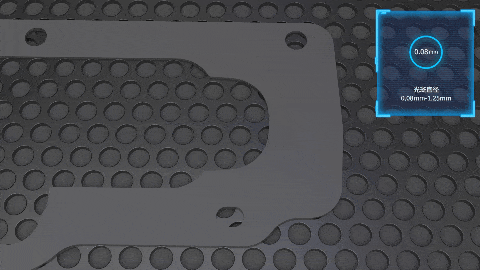

“Wolf 3D needed more than just a machine; they required a complete production and manufacturing optimization solution. The Lite 600 meets the precision and surface detail requirements for carbon fiber components,” said Mudassar. In addition, UnionTech provides Wolf 3D with value-added services such as photopolymer resins and slicing software, ensuring stable equipment operation and further supporting increased production capacity.

As highlighted in McKinsey’s Advanced Manufacturing 2025 report, when manufacturing precision crosses a critical threshold, the quality-cost curve across a product’s entire lifecycle can be optimized exponentially. “In the process of the manufacturing industry moving toward intelligent transformation, the core challenge for 3D printing remains controlling costs while achieving high-quality production. This is the direction all additive manufacturing technologies are continuously striving to improve.”

UnionTech’s SLA photopolymer 3D printing technology aligns perfectly with this market demand, offering core advantages that address these challenges:

High Precision: The device features a high-precision coating control system, enabling rapid and stable adjustment of the liquid level, with interlayer liquid level accuracy within 0.1 mm, effectively improving forming efficiency. It offers a build volume of 600 × 600 × 400 mm and supports adjustable layer thicknesses from 0.05 to 0.25 mm. Equipped with a 355 nm solid-state tripled-frequency Nd:YVO4 laser, it balances precision machining with industrial-scale production capabilities, making it suitable for high-precision additive manufacturing applications.

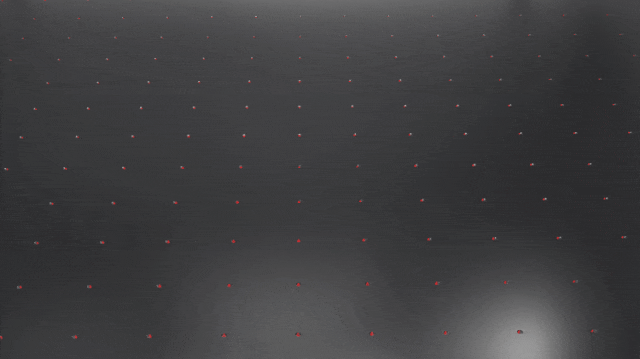

Smarter: Featuring a multidimensional perception and optimization system based on industrial-grade AI algorithms, the device integrates multi-sensor data streams to enable intelligent decision-making and dynamic optimization throughout the entire printing process. Its proprietary galvo self-calibration technology surpasses traditional calibration methods, improving automatic calibration accuracy by over 100%. This establishes an intelligent closed-loop control system from the optical path to forming precision, providing a reliable smart solution for the mass production of complex, high-precision components.

High Efficiency: By innovating the optical path with continuously variable spot technology, the optical system is simplified, and the laser beam can be dynamically adjusted according to printing requirements. Fine beams are used for high-precision areas, while wide beams enable rapid infill, significantly improving forming efficiency. At the same time, this technology greatly enhances the surface accuracy and smoothness of printed parts, reducing post-processing time and further boosting overall production efficiency.

Currently, carbon fiber, with its high strength and lightweight properties, is widely used across industries such as aerospace, transportation, sports and recreation, and industrial applications, fully meeting the core requirements of each sector. In the future, as technology continues to mature and the market further develops, carbon fiber is expected to find precise applications in an even broader range of specialized fields.