In September 2025, 3D printed footwear company Zellerfeld officially launched its latest FDM 3D printer, GEN3. The system offers significant improvements in speed, efficiency, and design flexibility. Zellerfeld’s long-term vision is to transition from traditional factory-based manufacturing to fully 3D printed footwear production, emphasizing personalization and sustainable manufacturing.

The Third-Generation 3D Printing System

From MONO1 to GEN3: The Evolution of Technology

Founded in 2018, Zellerfeld set out to redefine footwear manufacturing. With a deep understanding of 3D printing technology, founder Cornelius Schmitt introduced the company’s first printer, MONO1, which made fully 3D-printed shoes possible. As the technology evolved, Zellerfeld launched GEN2 in 2021, significantly boosting production efficiency and partnering with several luxury brands, including Louis Vuitton and Moncler, to create collaborative collections. These projects demonstrated how 3D printing could enable personalized, sustainable, and on-demand fashion—driving transformation across the industry.

Now, with its cutting-edge GEN3 printing system, Zellerfeld aims to achieve true mass production and make custom-printed footwear accessible to everyone, further solidifying its leadership in the 3D printed shoe market.

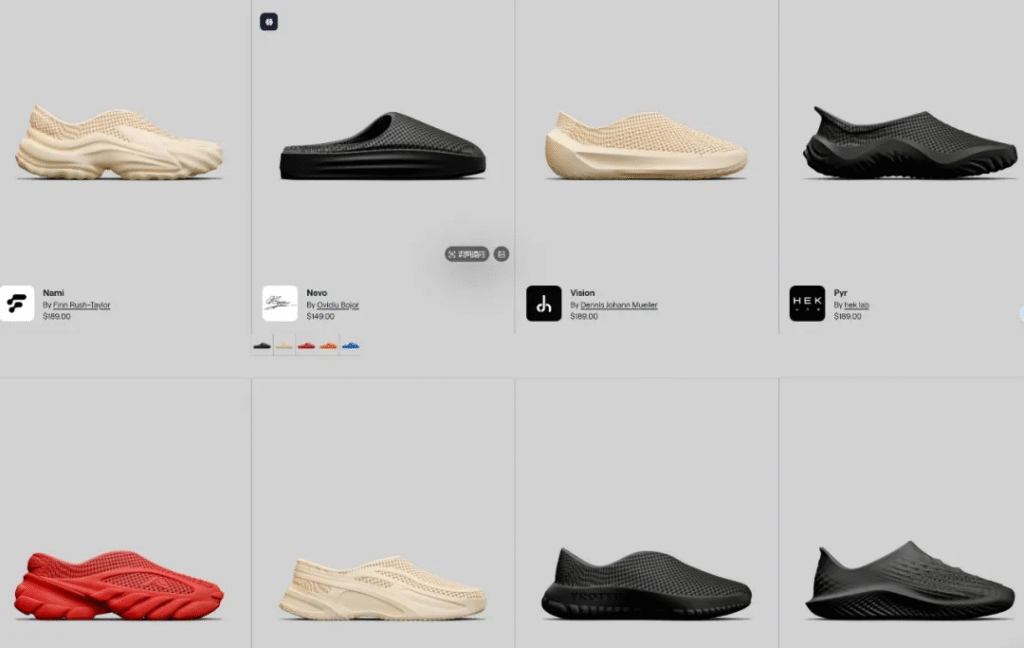

Building upon previous generations, GEN3 is three times faster than GEN2, supports multi-color printing, and offers fully automated operation with no human intervention required. Its flexible design makes it scalable for large-scale industrial applications. After years of testing and refinement, Zellerfeld has opened its platform to designers worldwide. Creators can upload their own designs, which are then produced and sold through the company’s system. By the end of 2025, Zellerfeld expects to offer over 1,000 on-demand designs, highlighting its growing accessibility and market reach.

Shoes Printed with the GEN3 3D Printing System

Expanding Zellerfeld’s 3D-printed footwear lineup, recent collaborations demonstrate the GEN3 system’s applicability to fashion and luxury markets. These partnership pieces showcase the technology’s ability to combine design freedom, rapid personalization, and scalable production—bringing designer-level aesthetics to on-demand manufacturing. The items are competitively priced at just over RMB ¥1,000, making 3D-printed designer shoes more accessible to a wider audience.

In July 2025, Hugo—a sub-brand of Hugo Boss—unveiled a loafer co-developed with Zellerfeld. The shoe was produced as a single, seamless piece using Zellerfeld’s proprietary software and hardware system, eliminating the need for traditional sizing, assembly, or inventory. Each pair is custom-made within hours, reflecting both personalization and the principles of a circular economy.

Zellerfeld also collaborated with designer Sean Wotherspoon, known for his use of unconventional materials and commitment to sustainability, to launch the Sean Double U Collection, featuring a sneaker and a slide. Both styles are manufactured from a single material without glue or stitching, highlighting the eco-friendly advantages of additive manufacturing.

Sean Wotherspoon and the Sean Double U Collection

In March 2025, British luxury brand Mallet London collaborated with Zellerfeld to launch the Nebula, its first fully 3D-printed shoe. The design reimagines Mallet’s signature Neptune silhouette through Zellerfeld’s automated production process, offering greater design flexibility, shorter lead times, and improved material efficiency.

Through these innovations and partnerships, Zellerfeld is steadily reshaping the footwear industry, driving a revolution in how shoes are designed and manufactured. The company’s vision — “a 3D-printed shoe on every foot” — underscores its mission to lead the shift toward a more sustainable and customizable future for footwear production.