On December 2, 2025, a mechanical engineering researcher from the University of Hawaiʻi at Mānoa, together with collaborators, published a comprehensive review on the fluid-mechanics challenges in Direct Ink Writing (DIW) additive manufacturing. The work aims to deepen the understanding of the physical principles underlying DIW and to explore ways to improve manufacturing reliability.

The related research findings were published in a paper titled “Fluid Mechanics Challenges in Direct-Ink-Writing Additive Manufacturing” in the Annual Review of Fluid Mechanics. The review compiles decades of research and provides a roadmap for printing a wide range of materials, from engineered tissues to large-scale architectural structures.

Taylor R. Ray, an associate professor in the College of Engineering at the University of Hawaiʻi at Mānoa, stated:

“Right now, 3D printing relies heavily on trial and error, requiring constant adjustments to formulations and settings to achieve success. We want to give engineers the tools they need to combine hands-on experience with physics-based predictions.”

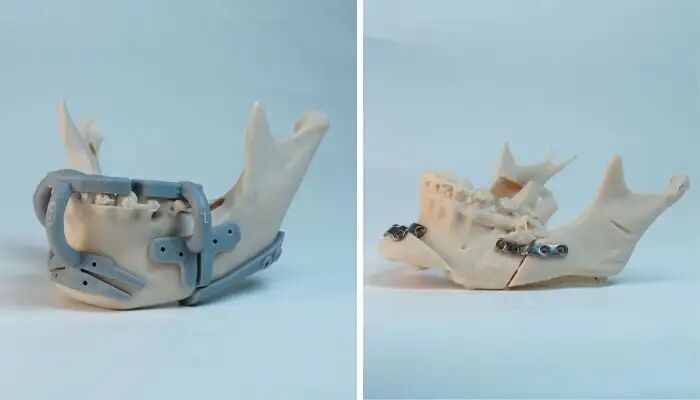

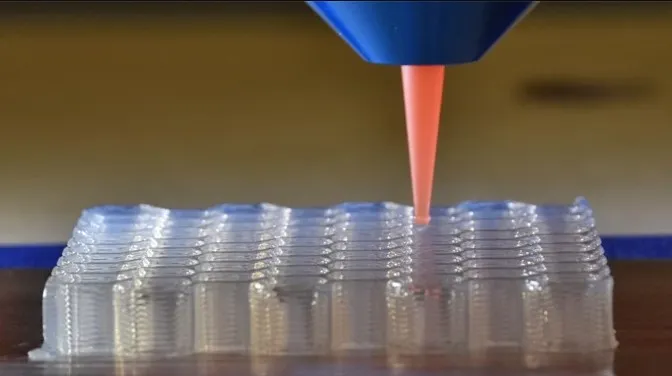

The printing method examined in this work is known as Direct Ink Writing (DIW), which operates much like decorating a cake. The “icing” must flow smoothly through the nozzle and then immediately hold its shape without melting or collapsing. This approach supports a wide range of printable “inks”—including living cells, concrete, ceramics, and polymer blends—enabling the creation of objects and geometries that traditional plastic-based 3D printing cannot achieve.

Alban Sauret, an associate professor at the University of Maryland and the paper’s lead author, explained:

“The paste-like materials used in Direct Ink Writing are complex fluids that exhibit both liquidlike and solidlike behavior depending on their environment. These remarkable materials have been studied for decades, but DIW introduces new challenges that require a deeper understanding of how such complex fluids behave during the printing process.”

Key Challenges

The paper identifies three critical moments that determine the success or failure of a print, each governed by the physical properties of the material.

First, the ink must be able to flow smoothly through the nozzle without clogging—a challenge that becomes particularly severe when the ink contains particles or fibers added for mechanical reinforcement.

Brett G. Compton, an associate professor at the University of Tennessee, noted:

“We’ve all experienced the frustration of a clogged pen or a leaking ketchup bottle. Now imagine trying to build precise 3D shapes using complex fluids filled with ceramic particles, cells, or fibers that must be pushed through a tiny nozzle without clogging the material or damaging the cells.”

Second, as the material exits the nozzle, it may break, buckle, or exhibit instabilities, all of which can lead to print failure.

Finally, once deposited, the material must be solid enough to retain its shape, yet fluid enough to bond with the previously printed layers. Achieving a successful print requires striking a delicate balance among these three factors.

Because DIW imposes stringent requirements on the ink—and because DIW inks can vary widely in composition—many questions remain unresolved, especially for particle-laden materials that offer stronger and more functional printed structures.

Ray added:

“We are still very much in the exploratory phase. Each answer leads to new questions and new areas to investigate, which is exactly why the three of us originally came together.”

The review also highlights several promising innovations, such as materials that harden on demand under light or heat, and ingeniously designed nozzles that help reduce clogging.

Sauret commented:

“In fact, there is a wealth of excellent research in the DIW field, but it is dispersed across disciplines that rarely overlap—such as medicine, chemistry, and civil engineering. With this review, we aim to present a coherent and fundamental fluid-mechanics framework that identifies the universal challenges and inspires new interdisciplinary research, ultimately making DIW more reliable and easier to apply wherever it is used.”