While 3D printing is generally too slow and too costly for mass-producing automotive parts, it’s a completely different story for ultra–low-volume vehicles like the Cadillac Celestiq. The car starts at $340,000, and only 25 units were built in its first year. For a model like this, GM engineers turned to additive manufacturing, producing more than 130 parts made from aluminum, stainless steel, and plastics such as nylon 11, nylon 12, thermoplastic polyurethane, and polypropylene.

After rounds of iteration focused on cost efficiency, reliability, and supply-chain standardization, GM believes that 3D-printing technology may eventually trickle down to mainstream, high-volume vehicles in the future.

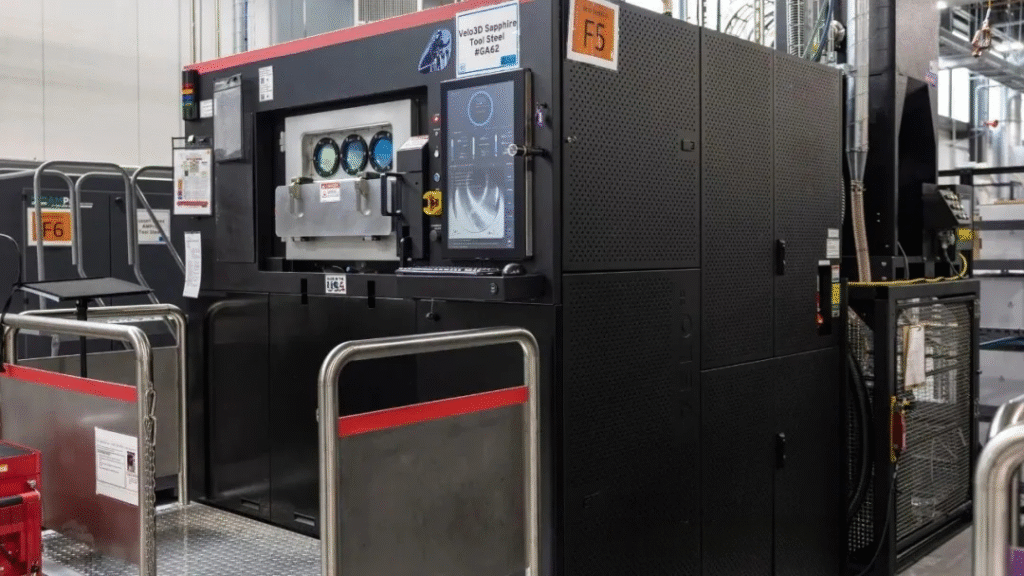

Before going into production, all 3D-printed components for the Cadillac Celestiq pass through GM’s Additive Industrialization Center, located at the company’s tech campus in Warren, Michigan. The 16,000-square-foot lab is filled with 3D printers — some as large as small sheds — capable of turning metal powder, polymer powder, and polymer filament into automotive parts. But the team doesn’t actually produce the parts here. Instead, the center validates the design and business case for each component before it’s handed off for production, which is usually done by suppliers.

“Our job is to bring the technology in, industrialize it, and then pass it into manufacturing,” said technical specialist Brennon White.

GM’s Additive Industrialization Center’s Velo3D metal 3D printer

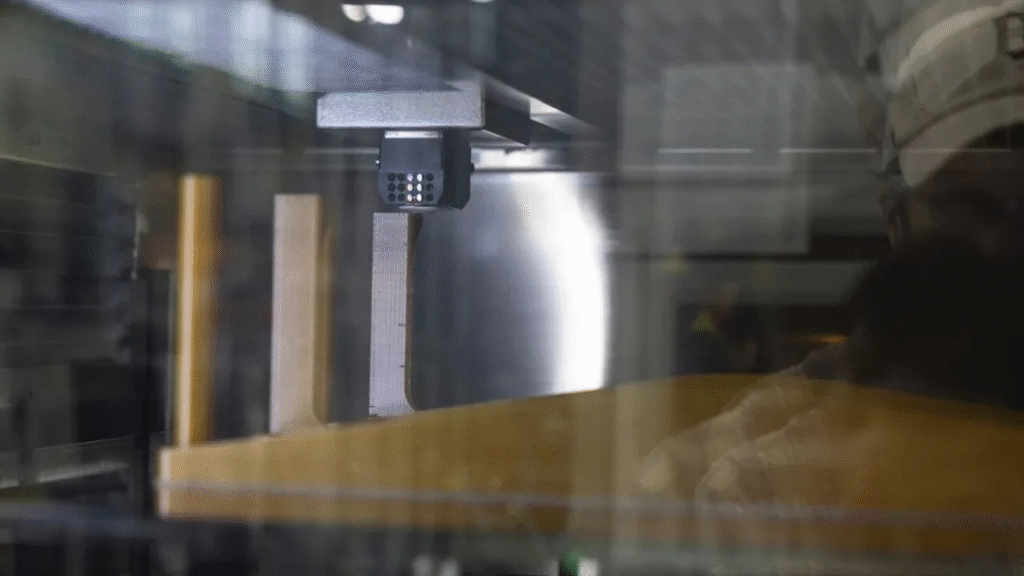

The EOS polymer 3D printer at GM’s Additive Industrialization Center

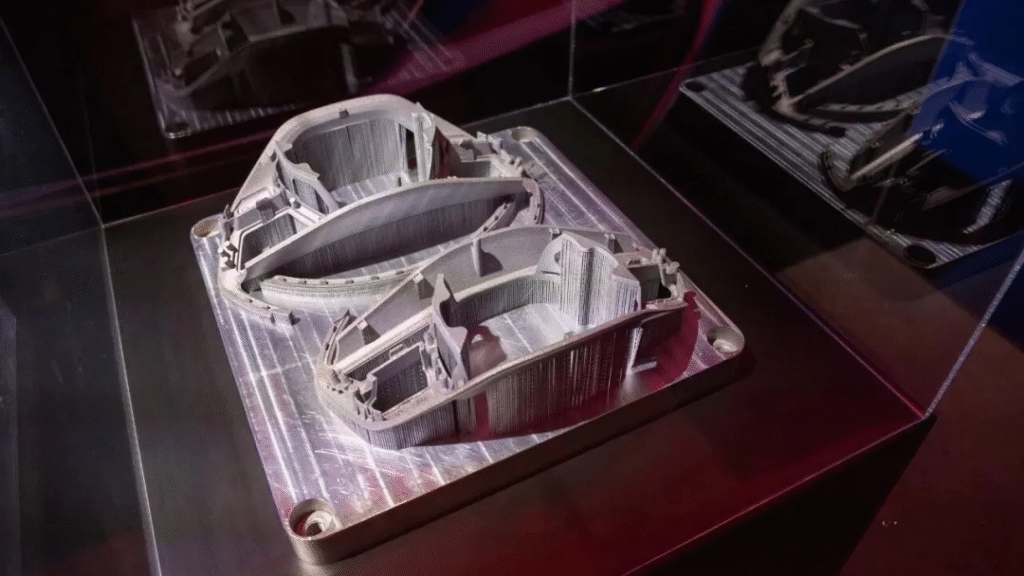

The aluminum steering-wheel décor panel is the largest 3D-printed component in the Celestiq — and the largest metal part GM has ever produced using additive manufacturing. It’s created using a laser powder bed fusion metal 3D-printing process and aluminum alloy. After printing, the part undergoes additional machining on a mill, which exposes the openings that form the four LED-backlit icons.

Designers of the Celestiq created an unusually slim B-pillar, leaving the seatbelt guide ring — normally hidden behind trim — completely exposed. Since there was no suitable part in GM’s existing catalog, the engineering and design teams turned to 3D printing to develop a stainless-steel component that serves both a safety function and an aesthetic purpose. According to executive chief engineer Tony Roma, the part is strong enough to lift the nearly three-ton Celestiq. This marks the first time GM has used additive manufacturing for a safety-critical component.

The design team also incorporated highly intricate 3D-printed details in hidden areas of the vehicle. The stainless-steel anchor for the passenger-seat leather armrest is polished to a mirror finish, and its hinged cover reveals an inner cavity when opened under force. Inside is a pattern inspired by Cadillac’s Mondrian motif and the Art Deco era (as shown below). The part is produced using metal binder jetting. After the “green” part is printed, it is placed in a sintering furnace for a 20-hour bake at temperatures reaching roughly 1,377°C, a process that causes the component to shrink by as much as 20%.

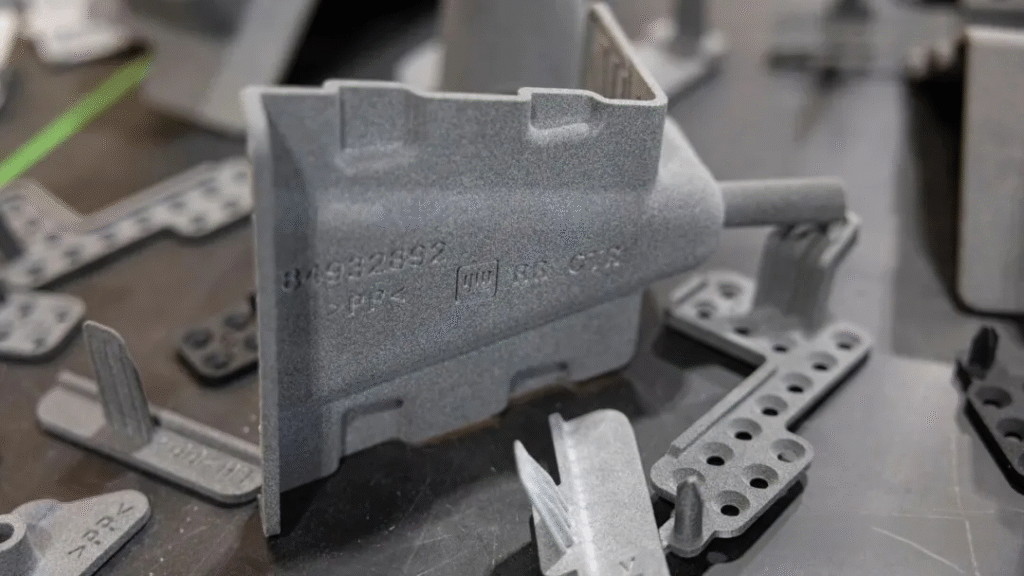

The Celestiq also relies on 3D printing to produce countless plastic components that buyers will never see or touch — such as the polypropylene brackets behind the front and rear bumpers that hold the ultrasonic parking sensors in place. According to Brennon White, one of the core strengths of the Additive Industrialization Center is knowing when and where to apply these technologies to deliver real economic benefits.

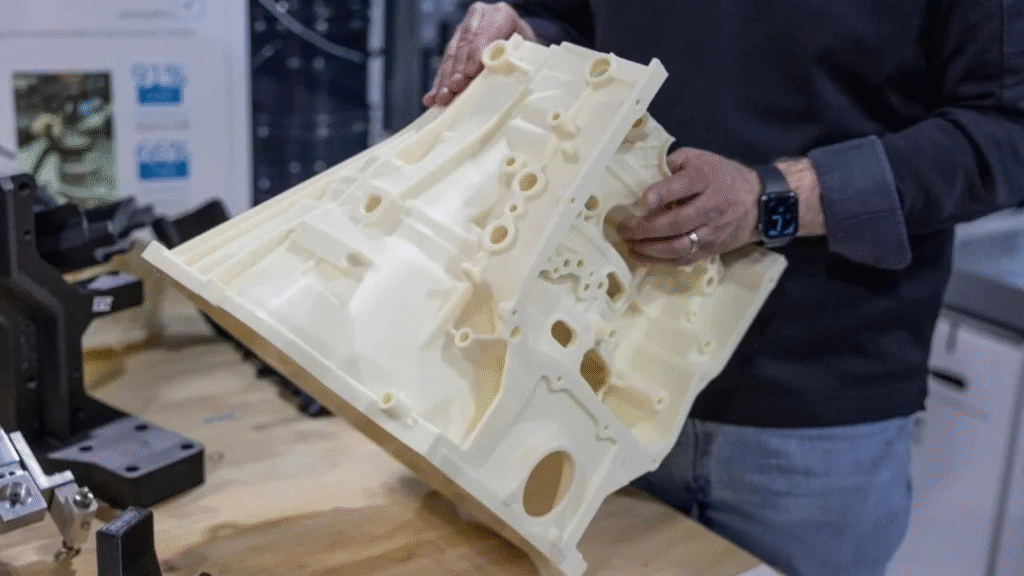

When the Celestiq team proposed 3D-printing the plastic sides of the glove box — parts that would ultimately be wrapped in leather — the Additive Industrialization Center initially concluded that the idea wasn’t commercially viable. But the design engineering team noted that the component would require two sets of prototype molds, not just one, to support the necessary design iterations, driving costs significantly higher. Once the decision was made to print the part instead, engineers fully embraced the flexibility of the process, making 27 design revisions along the way.

GM is clearly not about to start mass-producing 3D-printed parts for the Chevrolet Silverado — a truck that sells roughly half a million units a year — anytime soon. But additive manufacturing has already expanded beyond ultra-luxury flagship models and is being used more broadly throughout the company’s production operations.

Today, more than 15 GM assembly plants have at least one 3D printer on site, used to produce assembly aids and manufacturing tools. These machines use the same technology hobbyists have at home, melting polymer filament and depositing it layer by layer to create fixtures, jigs, molds, and even small parts. The process is much slower than printing with polymer powders, but it avoids the challenges of powder handling, making it more convenient and safer for factory environments. A Stratasys F900 on the factory floor can take more than a week to produce a large part.

The automaker is also applying 3D-printing technology to several higher-volume programs. Cadillac produces about 3,000 manual-transmission CT4-V and CT5-V Blackwing sedans each year, and every one of them comes equipped with a 3D-printed shift-knob badge, air-conditioning ducts, and metal wire-harness brackets.

When GM needed a quick fix for a spoiler-seal issue on one of its SUVs, the company turned to polymer powder-bed fusion and produced 60,000 parts in just five weeks. It’s an extreme example that demonstrates the potential of 3D printing in scaled production. But it also shows how the technologies now used in Cadillacs priced at $340,000 and above—after undergoing iterations in cost efficiency, reliability, and supply-chain standardization—may eventually make their way into Chevrolet’s core models in the $40,000 range.