Generative design has long been a mainstay in the aerospace industry, enabling engineers to reduce weight without compromising strength. However, seeing it applied to a desktop 3D printer marks a first in the field.

On October 22, 2025, London-based software company AiBuild, in collaboration with Generative Machine, unveiled a unique five-axis desktop 3D printer that embodies the fusion of AI-driven generative design and advanced additive manufacturing.

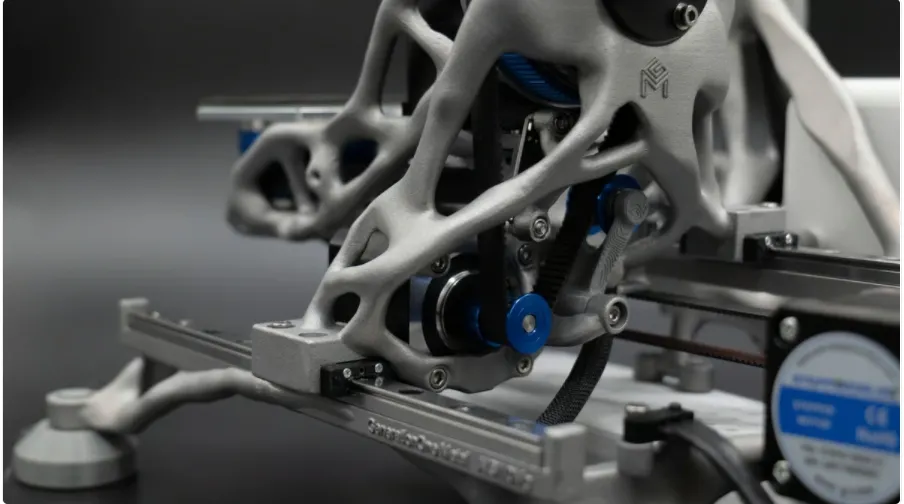

What makes this printer remarkable is its structural frame, which was created using generative design algorithms and manufactured entirely from aluminum alloy via 3D printing. The result is a lightweight yet extremely rigid framework, optimized for dynamic multi-axis motion and high-precision printing performance.

According to reports, AiBuild’s software is typically used to power large-scale KUKA robotic arm 3D printers and gantry systems the size of shipping containers, capable of fabricating complex, large-format components through highly coordinated deposition paths. This time, the company has miniaturized its industrial-grade printing capabilities into a compact desktop platform.

The new generative-design desktop 3D printer retains a classic cantilever structure with linear guides and standard motion components, yet introduces a breakthrough innovation — a metal 3D-printed aluminum alloy frame designed entirely through generative design algorithms. The result is a sleek, organic form that is both aesthetically striking and structurally optimized for rigidity and vibration control.

The printer is set to make its public debut at Formnext Frankfurt next month, where it will be available in limited pre-orders at Hall 12.1, Booth B79 (AiBuild stand). While the final pricing is still under discussion, it is expected to be comparable to other professional-grade desktop 3D printers on the market.

GenerationOne 5-Axis 3D Printer Features Fluid Generative Design Body

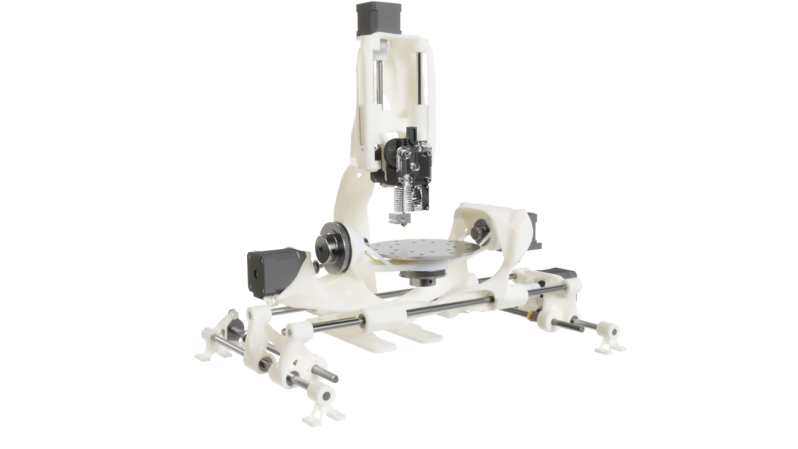

The new GenerationOne is an upgraded version of the Gen5X 5-axis 3D printer developed years ago by Ric Real, CEO of Generative Machine. The original Gen5X, an open-source design, stood out for its ability to self-reconstruct based on available components—an evolution of the early RepRap concept of self-replication and a breakthrough example of generative technology enabling machines to evolve themselves.

The new GenerationOne continues this philosophy of “a 3D printer printing another 3D printer,” but the collaboration with AiBuild marks a major leap forward. By integrating industrial-grade software systems, the machine can now fully unleash the potential of its five-axis coordinated motion system, delivering unprecedented precision and freedom in additive manufacturing.

The Original Gen5X 5-Axis 3D Printer

During the launch event, Real explained: “For years, desktop additive manufacturing has been constrained by traditional three-axis architectures. Our goal is to break that limitation and bring the advanced capabilities of robotics and large-scale additive manufacturing to the desktop environment.”

So, what exactly makes these capabilities groundbreaking? The core lies in a revolutionary innovation in material extrusion. The 5-axis robotic system enables non-planar printing, dynamically adjusting the nozzle orientation during operation. This allows for precise control over layer direction, significantly enhances structural strength, and eliminates the waste of excessive support materials.

In traditional desktop 3D printing, parts exhibit good strength along the X/Y axes but are structurally weak along the Z-axis, as they rely solely on interlayer adhesion. The 5-axis printer overcomes this inherent limitation through multi-dimensional rotational movement and advanced printing strategies, enabling structural reinforcement and fine surface finishing in any direction—something that conventional linear three-axis systems simply cannot achieve.

The GenerationOne’s Avant-Garde Design Makes a Stunning Visual Statement

The GenerationOne’s avant-garde design delivers a striking visual impact that immediately captivates the eye. Although its build volume (Ø140 mm × 180 mm) is not particularly large compared with today’s desktop 3D printers, the inclusion of features such as an interchangeable build platform and automatic bed leveling ensures a user experience that meets modern desktop standards.

Its material compatibility spans common filaments like PLA and PETG. Rather than investing in industrial-grade material capabilities, users are embracing the freedom to create without limitations—unlocking a new level of design expression using everyday materials.