How to Successfully Predict 3D Printing Production Results? Here’s a Complete Tutorial!As 3D printing technology penetrates deeper into industrial manufacturing, improving yield rates and shortening production and iteration cycles have become core strategies for cost reduction and efficiency improvement. Simulation is the key tool to achieve this, but only if the simulation software itself provides a sufficiently high level of accuracy.

However, does owning simulation software automatically mean you can precisely predict production results? Obviously not.

This article will provide you with a detailed tutorial, step by step, on how to use simulation to improve the reliability of 3D printing predictions—helping you truly achieve “knowing the outcome before printing.”

Key Point 1: Understanding Inherent Strain Prediction Values

Unlike structural simulation, the core of production simulation lies not only in the algorithm itself but also in the actual environmental parameters. This brings us to the concept of the inherent strain prediction value in real-world production.

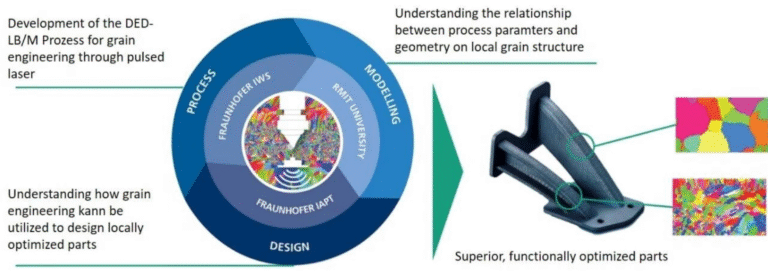

The actual parameters involved in the printing process can be divided into two major categories: material parameters and environmental parameters. For the commonly used inherent strain voxel method, accurately measuring the key inherent strain becomes crucial. Theoretically, inherent strain represents a fundamental property of the material itself.

However, additive manufacturing is essentially a process in which powder is melted and then solidified into a final part. During this process, numerous uncontrollable and immeasurable factors come into play—such as slight variations in powder composition or impurities, subtle differences in laser performance, and variations in atmospheric conditions within the build chamber. All of these factors eventually manifest as differences in the deformation state of the printed part.

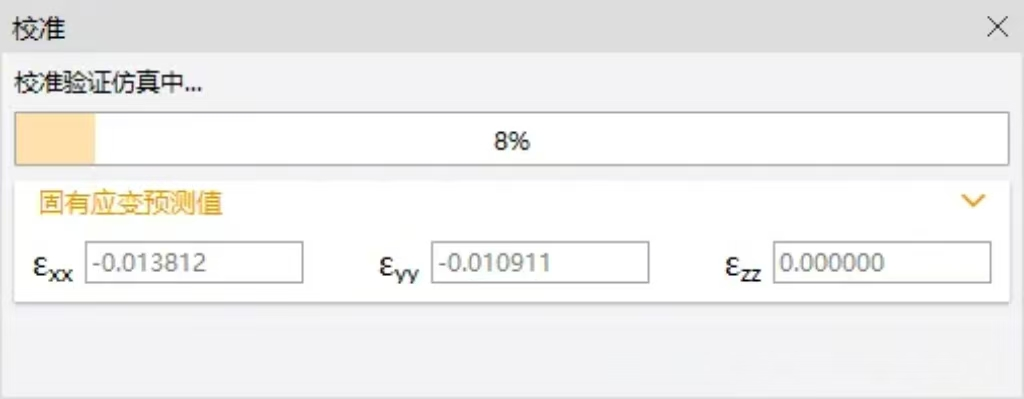

Inherent Strain Prediction

It may be more appropriate to regard the so-called inherent strain as a coefficient that influences the deformation state of a part. This coefficient can be back-calculated from the deformation behavior of the printed part, making the quality of the back-calculation algorithm the key to accuracy.

Key Point 2: Will Measured Parameters Alone Ensure Accuracy?

Suppose we obtain an accurate inherent strain coefficient and use user-measured material parameters—does that mean the simulation will be fully accurate?

The answer is: not necessarily! The size and appropriateness of mesh discretization also determine whether the simulation results are reliable. To exaggerate the example, if the same part is divided into 10 elements versus 100 million elements, the difference in accuracy is self-evident.

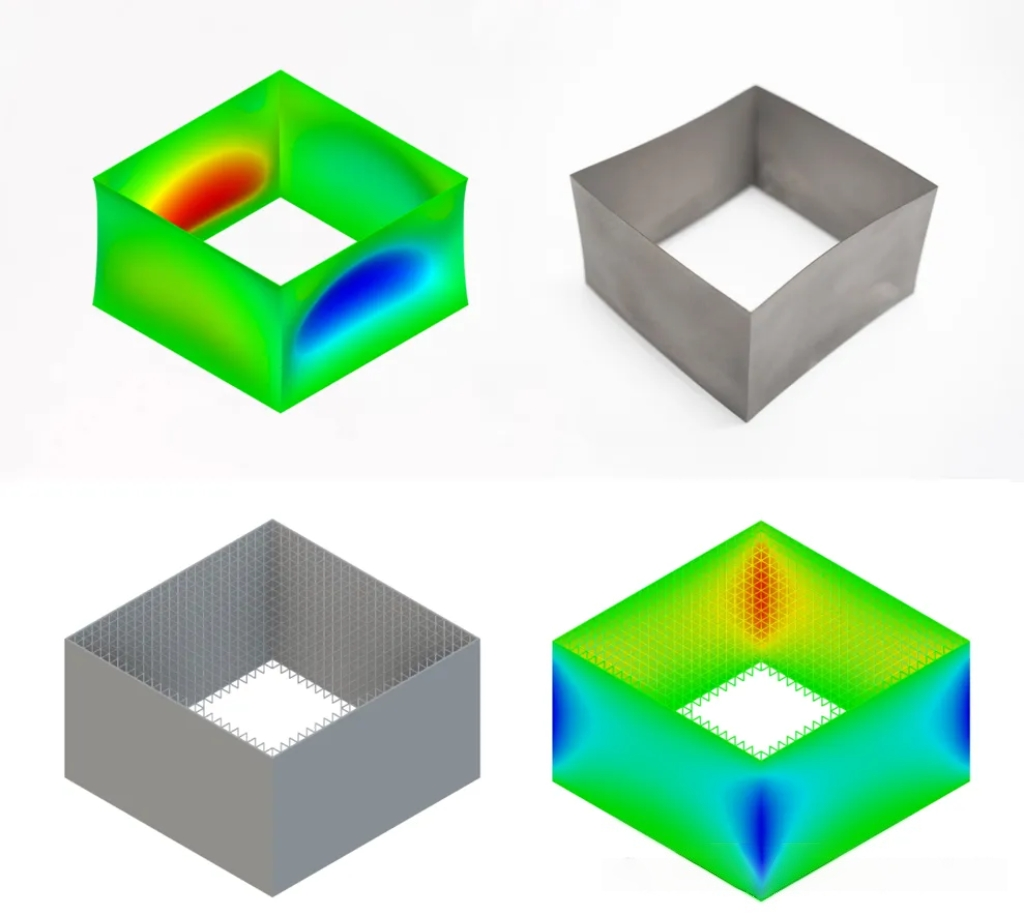

For instance, consider a thin-walled square container: if only a single-layer voxel mesh is used, the simulation cannot accurately capture the buckling phenomenon that occurs during actual printing. At least a two-layer mesh is required to reflect the real structural behavior. Therefore, the rationality of mesh division becomes another critical factor in ensuring simulation accuracy.

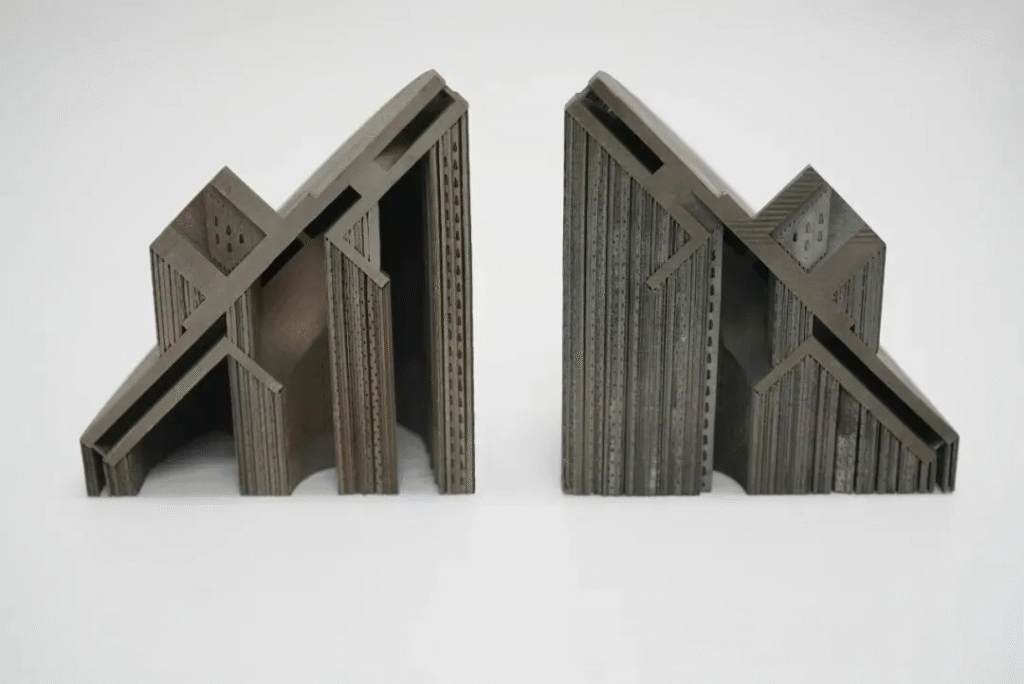

Comparison of Thin-Walled Square Parts Before and After Lattice Addition

Therefore, when the mesh resolution is refined enough to capture the critical features of interest—combined with high-performance computing—it becomes possible to predict buckling deformations in thin-walled structures within a short time.

Practical Result: Significant Reduction in 3D Printing Supports

For example, in the optimization of an impeller printing process by a certain enterprise, VDE leveraged its highly efficient GPU parallel computing architecture. This enabled process simulations to be performed within a limited time frame, greatly shortening the overall process cycle and demonstrating remarkable efficiency in rapid iterations.

Previously, the impeller manufacturing plan relied on full-scale supports, which not only resulted in long printing times but also caused significant material waste. Through multiple rounds of simulation-driven optimization using VDE, the support structures were ultimately reduced by 60%, leading to a substantial improvement in efficiency.

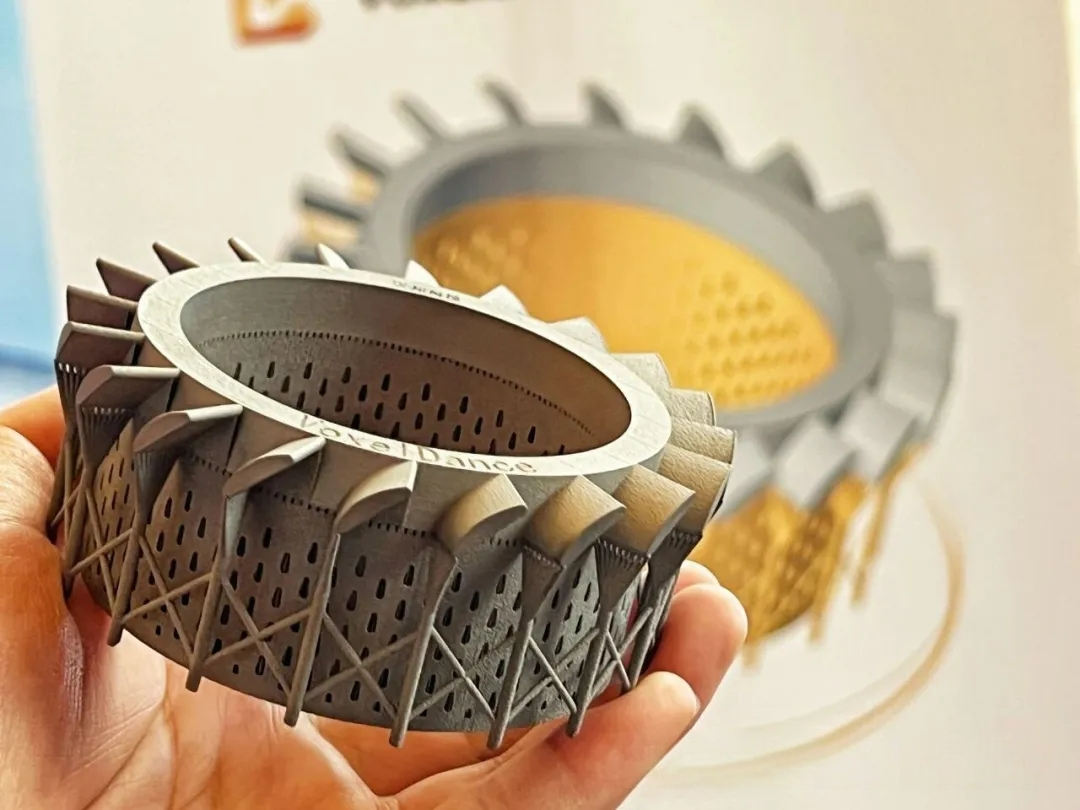

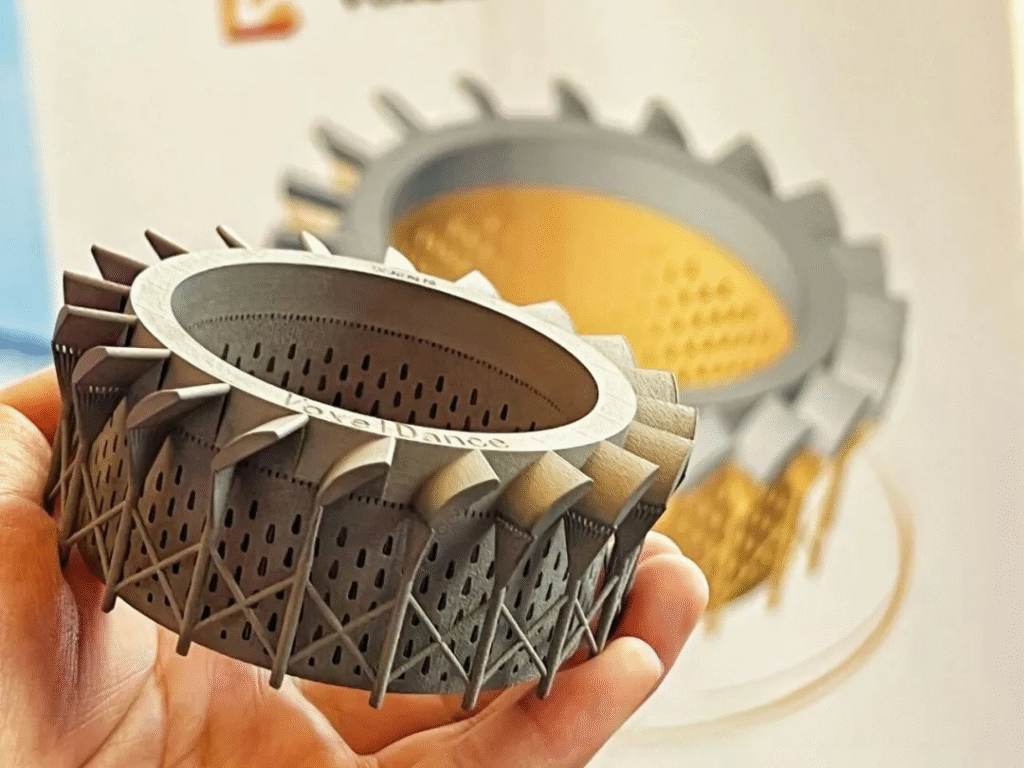

Impeller Model

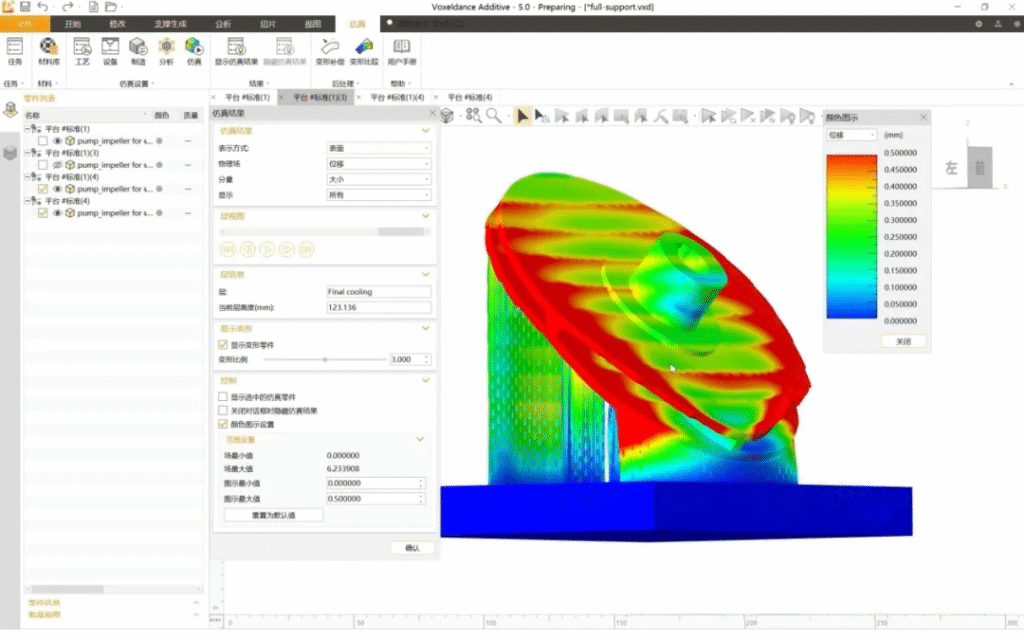

First-Round Simulation: Identifying Core Deformation Areas

A simplified support structure was used in the simulation to quickly locate the critical regions of the impeller with the most significant deformation. This provided clear guidance for subsequent support optimization.

Using Simplified Support Structure for Simulation

Second-Round Simulation: Optimizing Shape-Control Supports and Mitigating Process Risks

After adding shape-control supports in areas with significant deformation, another round of simulation was conducted. The results showed a clear improvement in overall deformation. However, potential process risks such as scraper collisions during printing were identified, indicating the need for further adjustment of the support layout.

After Adding Shape-Control Supports in High-Deformation Areas for Re-Simulation

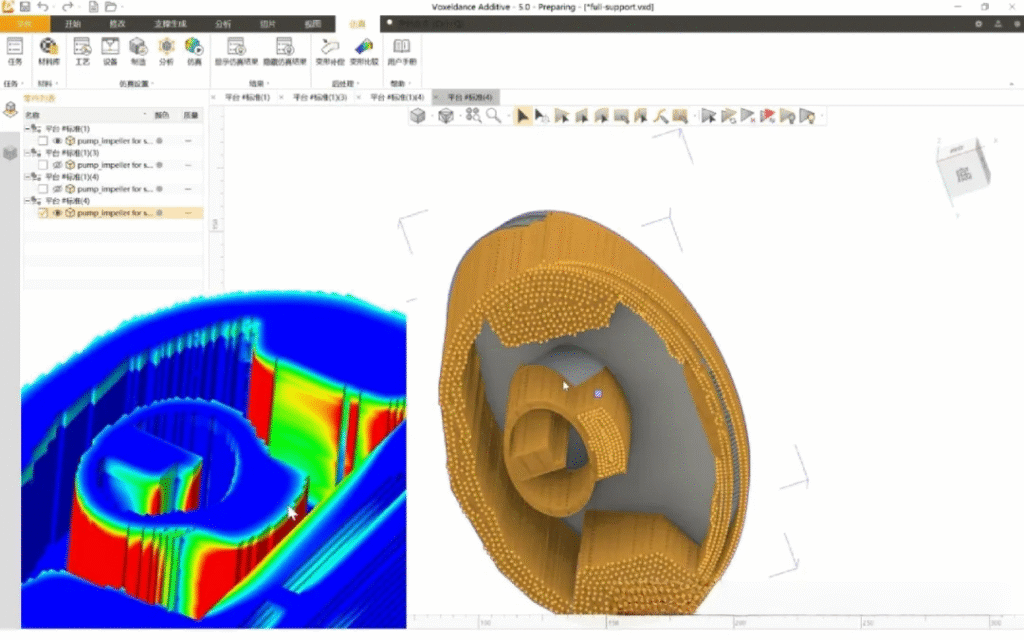

Third-Round Simulation: Eliminating Risks and Achieving the Optimal Solution

To address the risk points of scraper collision, additional high-strength supports were introduced, followed by a third round of simulation. The final results demonstrated that all process risks were completely eliminated, and the overall deformation of the impeller was effectively controlled within a reasonable range.

Adding High-Strength Supports and Completing the Third Simulation

Throughout the optimization process, the company successfully carried out three rounds of simulation and two process upgrades within a limited timeframe. As a result, the overall support usage was reduced by 60% compared to the original scheme, significantly shortening printing time while achieving dual optimization in both material consumption and production cycle.

3D Printed Impeller Component

Rapid Iteration of Large-Scale Production Schemes

Beyond predicting production outcomes, what else can simulation software be used for?

One key application is virtual iteration of process schemes. Traditionally, engineers rely on years of industry experience to refine and iterate part designs, which is certainly feasible. However, when production schedules become tight and process preparation time is limited, the iteration speed often fails to meet requirements. Therefore, achieving maximum process optimization within a constrained timeframe has become a pressing challenge for manufacturing enterprises.

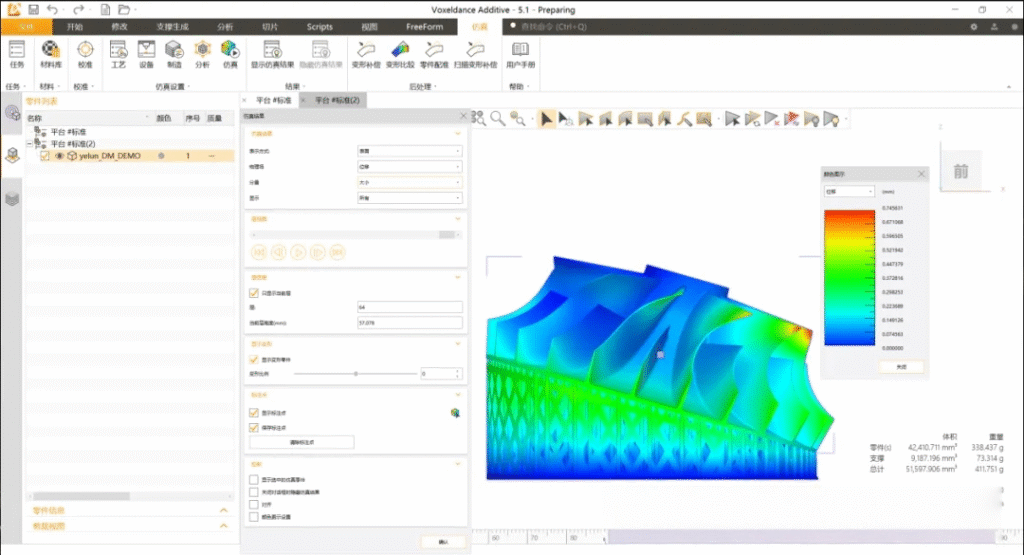

VoxelDance Engineering (VDE) Simulation Suite

Traditional simulation software often takes an entire day to complete a single simulation. The VoxelDance Engineering (VDE) print process simulation suite, through innovative algorithms and workflow design, now enables up to five full simulation and distortion compensation cycles in a single day, dramatically boosting R&D efficiency.

Key Features

Purpose-built Algorithms for Additive Manufacturing

Specifically developed for AM, avoiding redundant code found in general-purpose software.

Leveraging GPU parallel computing architecture, achieving 5–10× higher computational efficiency compared to CPU-based algorithms.

Ultra-large File Processing Capability

Proven through stress testing, a single 18 GB model file can still run smoothly.

Fully capable of handling highly complex parts in aerospace, heavy equipment, and other demanding industries.

Local AI Module & Adaptive Meshing

Built-in local neural network AI assists in extracting inherent strain values.

Supports adaptive meshing with computation on models exceeding millions of elements.

Comprehensive Simulation & Post-processing

Enables thermal, mechanical, and thermo-mechanical coupled simulations.

Covers the entire post-processing workflow, with results including temperature, displacement, stress, and other professional datasets.

Precision Compensation Functionality

Supports both linear and nonlinear compensation based on simulation outcomes.

Direct comparison of scanned parts against design models is possible, allowing targeted geometry compensation based on scan data.