On January 12, 2026, the Zhongke Aerospace Lihong-1 Remote-1 spacecraft successfully completed its suborbital flight test mission at the Jiuquan Satellite Launch Center. The return capsule landed successfully and was recovered through the parachute system. The first flight carried a microgravity laser additive manufacturing return scientific experimental payload, as well as space radiation-induced mutagenic rose seeds and other items.

CAS Aerospace elaborated on the details of the microgravity metal 3D printing in this mission:

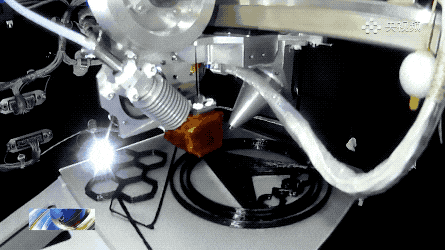

The microgravity laser additive manufacturing return scientific experimental payload (LAM-MG-R1) carried on this first flight is a technology verification payload for space metal additive manufacturing, developed by the Institute of Mechanics of the Chinese Academy of Sciences. The primary objective of this payload is to verify the feasibility of laser melting wire metal additive manufacturing technology in space microgravity environments. It is expected to provide valuable scientific data on key process parameters, geometric characteristics, and performance parameters of space laser melting wire metal additive manufacturing. This mission has laid a solid foundation for the development of the basic theory and key technologies of space metal additive manufacturing, and provided valuable experience for developing technologies such as long-term in-orbit metal additive manufacturing and in-situ repairs in space environments.

CAS SPACE: The Zhongke Aerospace Lihong-1 Remote-1 spacecraft successfully completed its suborbital flight test mission, with the return capsule landing successfully.

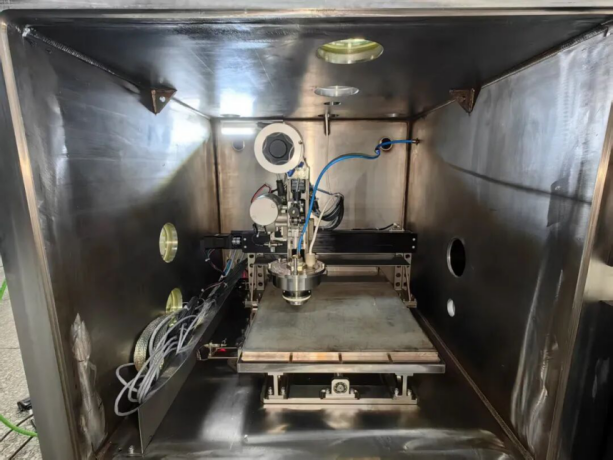

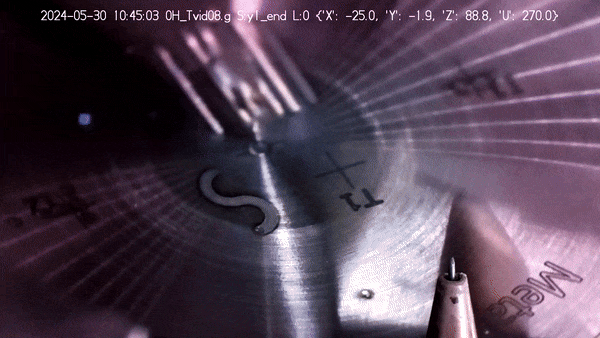

In the field of space metal 3D printing, the European Space Agency (ESA) achieved the first-ever space metal 3D printing in 2024. A 180 kg metal 3D printer built by Airbus printed a precision part that was 9 cm high and 5 cm wide on the International Space Station. The entire production process took approximately 40 hours.

From June to August 2024, astronauts began the process of printing parts. The engineering team had to handle uncertainties in the microgravity environment and implemented a precise operational strategy. They also equipped a set of systems for remote control and monitoring of the payload via its telecommunications link, ensuring that every operation was stable and reliable. During the printing process, the team continuously adjusted parameters to ensure print quality. In March 2025, the first metal 3D printed part produced in space returned to Earth for testing. However, no research results have been published over the past year regarding 3D printing technology reference.

On April 11, 2025, Science and Technology Daily published an important news item stating that the High-Energy Beam Generator Laboratory of the China Aviation Manufacturing Technology Research Institute had made a breakthrough in the field of “space 3D printing” technology. This laboratory successfully applied a cold cathode electron gun to achieve precision titanium alloy forming in a simulated microgravity environment, completing “space-grade” 3D printing.

The report pointed out that the technology has successfully achieved electron beam melting wire forming in simulated microgravity conditions. Furthermore, the research team has developed a “space-grade” 3D printing prototype, with equipment that is miniaturized and lightweight, significantly reducing launch costs.

“Space-grade” 3D Printing Prototype Internal Structure

From the available information, both laser and electron beam technologies are suitable for space printing. However, based on current understanding, laser space printing focuses on high precision, while electron beam space printing focuses on high energy and efficiency. According to the data, electron beam 3D printing still requires helium gas protection, mainly to prevent charge accumulation in the vacuum environment. The helium ions in the gas interact with electrons in the vacuum environment, neutralizing the charge buildup and preventing electron beam spot fluctuations and discharges.

Space 3D Printing Technology Development Progress

As an emerging technology, space 3D printing has made significant advancements in recent years, not only achieving breakthroughs in technology but also demonstrating great potential in practical applications.

- First Human Space 3D Printing

In 2014, humans sent the first 3D printer to space, successfully printing several tools and components, including a wrench, on the International Space Station. The test confirmed the feasibility and effectiveness of 3D printing technology in a microgravity environment, laying the technological foundation for future space manufacturing. Since the first test in 2014, space 3D printing technology has continued to progress. In addition to printing traditional tools and components, there have been attempts to print more complex objects in space, such as biological tissues and construction materials.

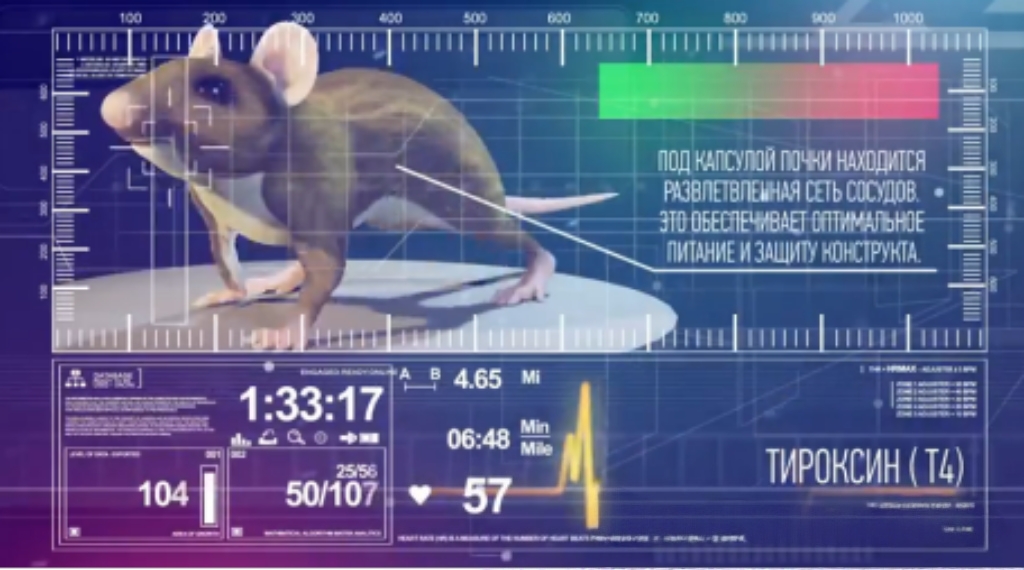

- First Space Biological 3D Printing

In 2018, Russian cosmonauts on the International Space Station used a 3D bioprinter to print the thyroid gland of a laboratory mouse, marking the first time a biological organ was printed in space. This achievement not only demonstrated the feasibility of space biological 3D printing but also paved the way for future printing of more complex human organs and tissues in space.

- First Continuous Fiber Reinforced Composite 3D Printing in Space

In May 2020, China successfully launched the first space-based continuous fiber reinforced composite 3D printer aboard the Long March 5B manned spacecraft experimental module, becoming the first country in the world to achieve this technology. This technology uses continuous fiber bundles and thermoplastic polymers as raw materials. Through an independently developed printhead, it achieves composite impregnation and fused deposition, enabling the integrated preparation and forming of composite materials.

- First Space-Based Laser Metal 3D Printing

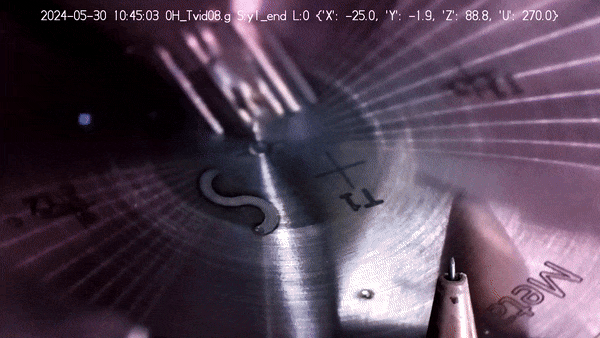

In 2024, a metal 3D printer manufactured by Airbus successfully completed the first deposition of liquefied test lines on the International Space Station, printing a melted “S-curve.” This marked the successful calibration of the 3D printer, which then began printing sample parts.

Whether for space station maintenance, on-demand tool manufacturing, or the replacement of installation interfaces and mechanical components, in-orbit manufacturing has demonstrated immeasurable value, opening up new possibilities for future space habitation and exploration.