Recently, 3DPrint invited key representatives from prominent companies in the metal additive manufacturing field to offer their predictions for the industry’s development in 2026. Their insights were sharp and directly addressed the practical engineering applications in the sector.

Metal additive manufacturing technology and the industry are evolving in different directions. The commercialization and reduction of manufacturing costs have driven the production of millions of components across industries such as consumer electronics, machinery, and dentistry. At the same time, the demand for large parts in hypersonics and aerospace sectors has increased the need for high-end, critical components.

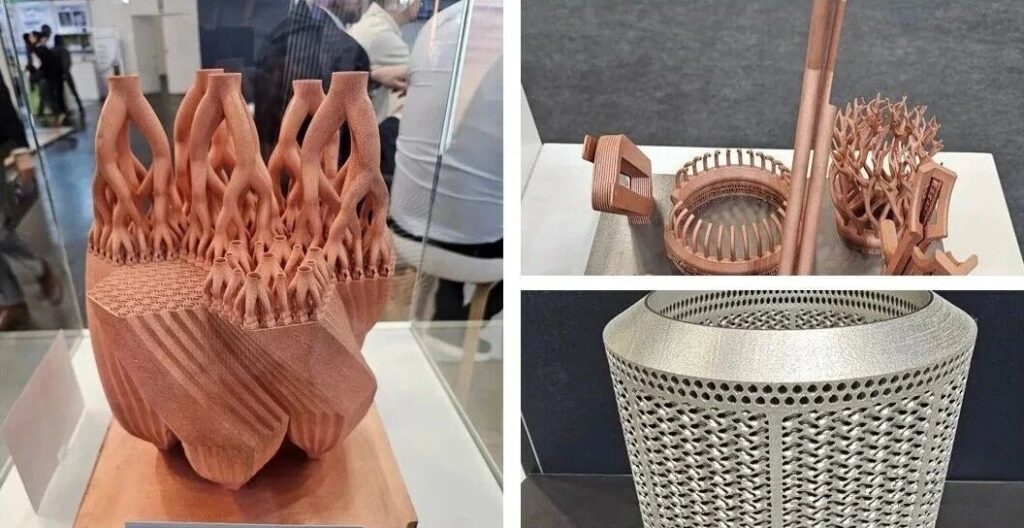

Some companies focus on differentiation, unique capabilities, and cutting-edge technologies, while others focus on automation, reducing operational costs, and increasing production volume. Today, the 3D printing industry has access to large, affordable, and truly mass-producible equipment. At the same time, there is growing interest both within and outside the industry in technologies beyond Laser Powder Bed Fusion (LPBF), such as binder jetting, Directed Energy Deposition (DED), and electron beam technologies, with more people dedicating efforts to the instant creation of new alloys and materials.

Representatives from Barnes Global Advisors and Metal Powder Works:

“I expect that the most significant improvement in the additive manufacturing field by 2026 will be cost-effectiveness: printer production efficiency will increase, printer prices will decrease, and thicker print layers will eventually drive component costs in the right direction. We also need to address the pursuit of extreme process elements, such as excessively high demands for powder sphericity and specific processes, which, while reasonable in the early stages of R&D, must be balanced with cost, manufacturing cycles, and overall efficiency in commercial production. The current core task should be scaling up usage, system verification of comprehensive benefits, and achieving the goal of designing for additive manufacturing through volume scaling, thus making the process a routine practice.”

CEO of REM Surface Engineering:

“I believe that by 2026, application development, certification, and scaling will continue to experience steady growth. Many original equipment manufacturers (OEMs) are focusing on increasing production capacity and improving part quality and production efficiency through technological advancements. These improvements validate the current view that certification and production are the focal points. In terms of the breadth of new part certifications in the U.S., the aerospace sector will be at the forefront. Laser Powder Bed Fusion (LPBF) will remain the mainstream printing technology in this field, but with the advancement of the U.S. Maritime Industrial Base Initiative, it is expected that Directed Energy Deposition (DED) technology will see significant growth in the coming years.”

Vice President of Nikon Advanced Manufacturing Technology:

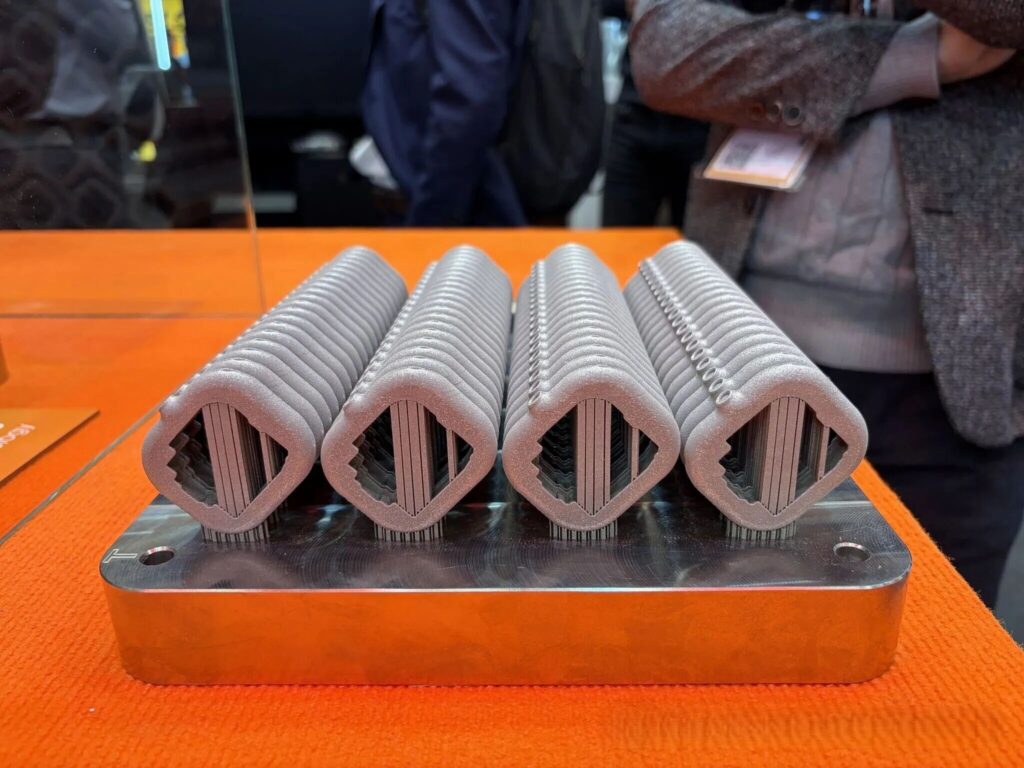

“In the coming year, industrial metal additive manufacturing will clearly transition from the concept validation and low-speed initial production stages to the true full-speed mass production phase. We will see significant growth in the use of metal additive manufacturing in the weapon systems and ammunition sectors. We expect that the number of certified flight parts across multiple platforms will continue to rise, and in addition to traditional alloys, more material data and qualified materials will emerge. I believe we will witness the digital integration at the factory level and the rise of metal additive manufacturing plants. Production orders will primarily come from defense, aerospace, and energy sectors, with ammunition, satellite parts, heat exchangers, RF applications, drones, autonomous underwater vehicles, unmanned systems, industrial gas turbines, and marine applications leading the growth.”

Material innovation will focus on lightweight aluminum alloys (more high-performance aluminum alloys will be used in new designs, replacing existing alloys), high-temperature alloys, corrosion-resistant marine alloys, and tool steels that enable large-scale mold production. The winners in 2026 will be those companies that view additive manufacturing as a manufacturing system rather than just a novelty technology, and who optimize manufacturing scale, consistency, and total cost with high-productivity additive manufacturing systems.

Additive manufacturing is no longer just about what can be printed; it is about being able to produce quickly, reliably, and repeatedly at low cost and high efficiency.