Application Expert with 23 Years of Experience in the 3D Printing Industry:

“The development of additive manufacturing will continue to shift from capability building to industrial applications and scaling. The standard for measuring progress will no longer be the number of new machines but whether additive manufacturing can be accepted by regulatory environments. This will require clearer certification, repeatable processes, feasible economic benefits, and evidence chains that can be accepted by procurement, insurance, and regulatory bodies.

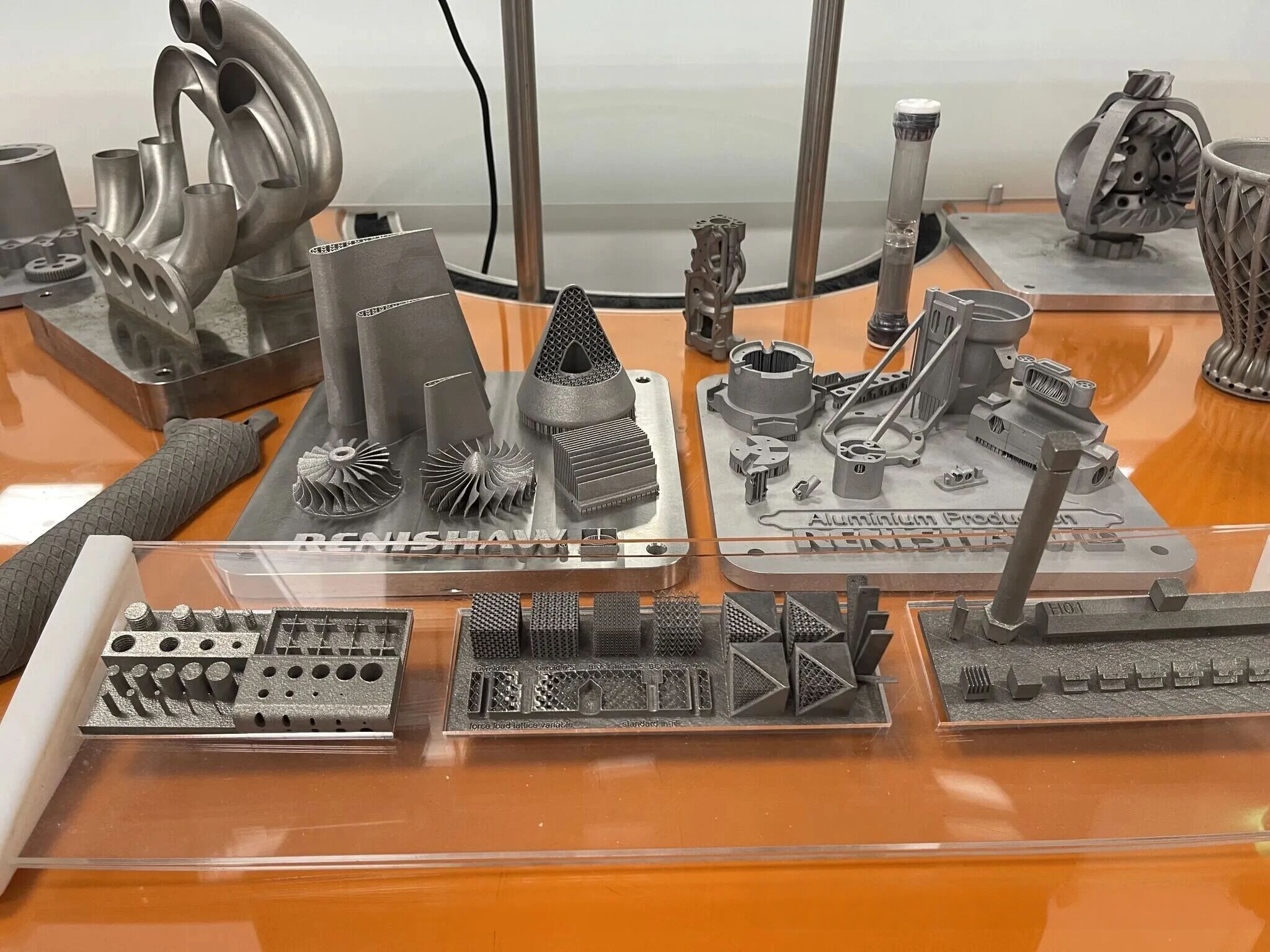

The focus is shifting from novelty to maturity and certification. In the metal sector, Laser Powder Bed Fusion (LPBF) will remain the primary production method, but growth will be gradual. Directed Energy Deposition (DED) will continue to dominate in maintenance and large-scale applications due to its high demands for cost, productivity, and material efficiency. Electron Beam Powder Bed Fusion (EBPBF) will solidify its position in the high-temperature alloy, titanium, copper, and energy-related material sectors. Procurement behavior is also changing, with decisions increasingly based on trust, evidence, long-term support, and whether additive manufacturing can be effectively integrated into existing production capabilities. China will continue to actively scale up its additive manufacturing, with its iteration and improvement speed outpacing many European and American manufacturers.”

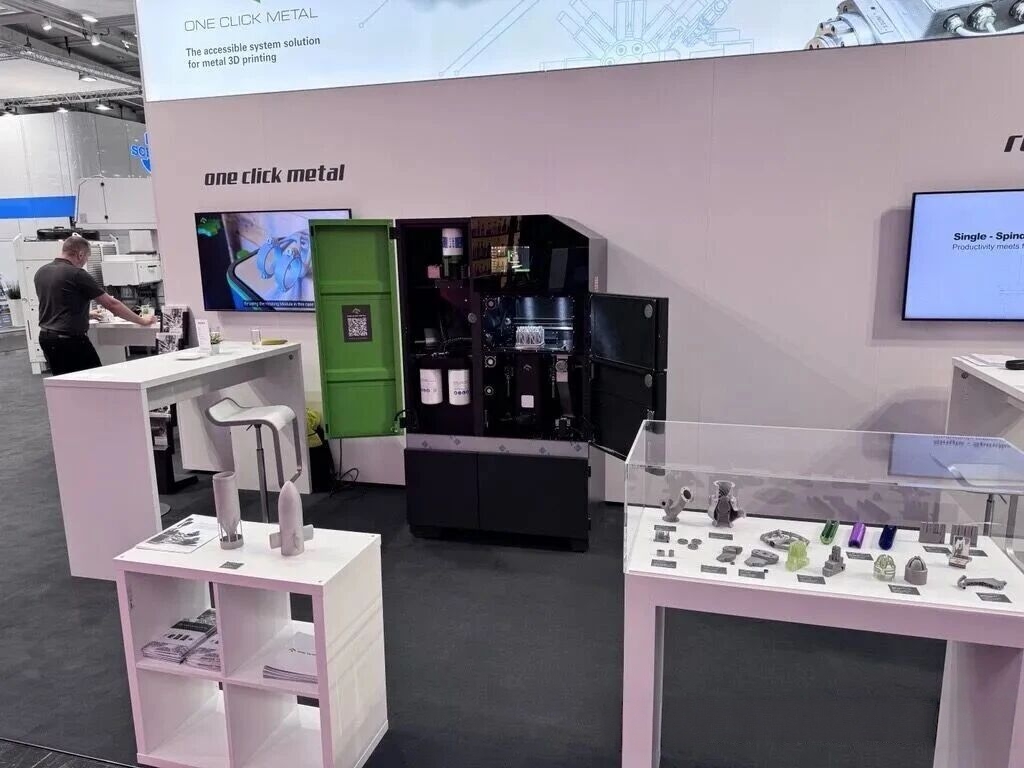

CEO of One Click Metal:

“The increasing number of consumer-grade metal 3D printing applications on the market is making LPBF technology more popular among end users and will increasingly be used to produce a wide variety of products. With solutions that are ready for production, easy to integrate, and reasonably priced, we are driving this development forward.”

“My personal suggestion to all Laser Powder Bed Fusion (LPBF) companies is to set up a secret R&D department to develop an entry-level system priced under $100,000, which could bring tens of thousands of new users to the market each year. In my view, this is the only way to respond to the growing competition and a smart strategy for expanding the market and cultivating our own customers. Sure, Bentleys are nice, but if we truly want everyone to be able to drive, we should build cars like Ford did. During uncertain economic times, reducing capital expenditures or component costs is the key to improving adoption rates.”

“Similarly, while low-cost LPBF parts are great, what about when using Directed Energy Deposition (DED) technology, which costs only one-tenth of the LPBF parts? How do we address that? The maintenance and direct production of low-cost parts are expected to make 2026 a breakthrough year for DED technology. We’ve already seen its strong development momentum.”

HP Global Sales Manager for Metal 3D Printing Solutions:

“The future growth of industrial additive manufacturing will primarily be driven by mass production, with a particular focus on metal applications. As manufacturers shift towards larger-scale production, the demand for robust and scalable additive manufacturing solutions continues to grow. Binder Jetting (BJ) technology was previously overhyped, often seen more in PowerPoint presentations than in factory workshops. HP is working to change that.

Metal Binder Jetting (MBJ) technology is gradually maturing and becoming suitable for larger-scale applications. As the technology continues to evolve, larger production scales and the introduction of new materials will drive demand growth. MBJ technology is expected to make significant progress, overcoming past limitations and achieving substantial market advancement. I predict that large-scale applications will demonstrate the advantages of MBJ technology and accelerate its adoption.”

Mass production is the future of binder jetting 3D printing. If suitable manufacturing enterprises can be found, ensuring stable operation of printing units, and effectively controlling settings, failures, and distortions at large scales, MBJ will be able to produce millions of specific parts in a highly cost-effective manner. With the right technological integration, all of this could become a reality sooner than we expect.

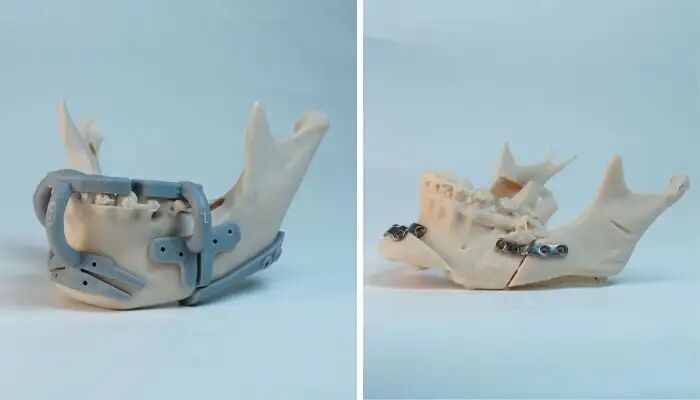

Industry experts are more optimistic than ever about the growth prospects of electron beam, laser powder bed fusion (LPBF), binder jetting, and directed energy deposition (DED) technologies. With application-oriented, proven value propositions, these technologies are seeing comprehensive development. They are no longer just used to manufacture rare, highly classified parts but are also being employed to print everyday items.

Will 2026 be the breakthrough year for DED technology? This will open up new parts, applications, and fields more quickly. Additionally, will it be possible to successfully create new alloys that can open up new industries? Moreover, will more companies succeed in manufacturing low-cost LPBF systems? If achieved, thousands of new companies could use LPBF technology to manufacture parts, making its market size far exceed any other technology.