Laser systems based on Gaussian beams are widely available on the market, offering high technological maturity and relatively low costs. This makes Gaussian beam processing highly prevalent in metal material applications. Gaussian beams exhibit excellent focusing performance, enabling high energy density concentration—crucial for processes such as welding, cutting, and additive manufacturing of metals. The L-PBF (Laser Powder Bed Fusion) 3D printing process based on Gaussian beams is relatively mature, featuring stable equipment and straightforward operation.

However, research has shown that Gaussian beams have a higher energy density at the center and lower energy density at the edges, resulting in significant temperature gradients and complex melt pool instabilities where the laser interacts with the metal powder. This uneven energy distribution can lead to the vaporization of low-melting-point alloying elements, causing “melt pool instability” and reducing process stability. As a result, several issues arise, including incomplete melting, keyhole effects, spattering, and lower process efficiency, ultimately leading to increased porosity, parameter sensitivity, and undesirable impacts on microstructure and mechanical properties.

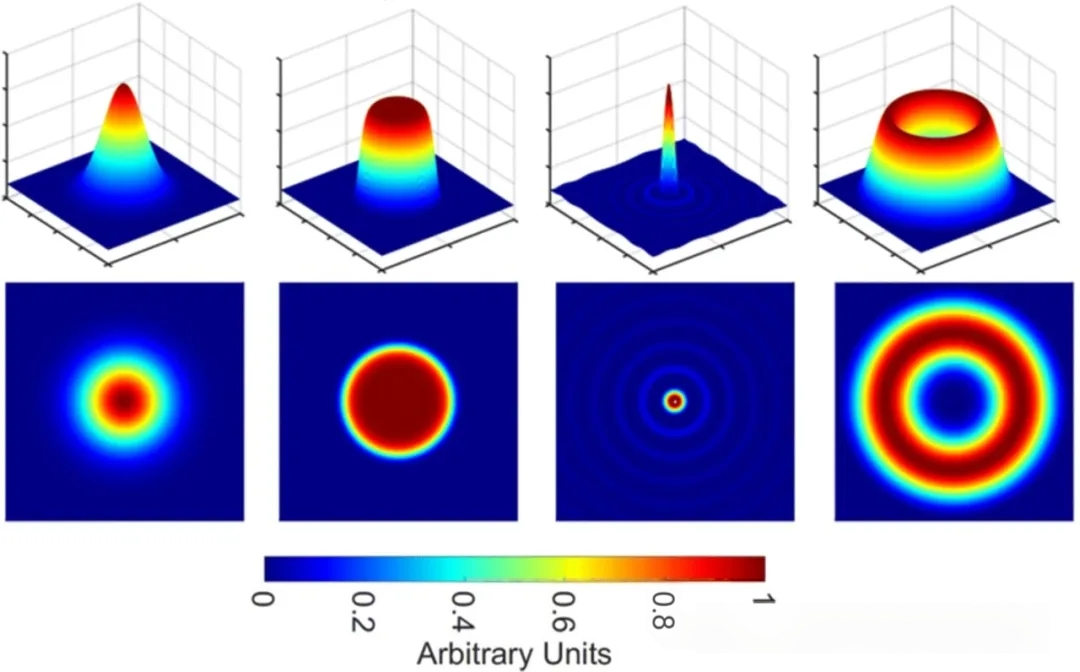

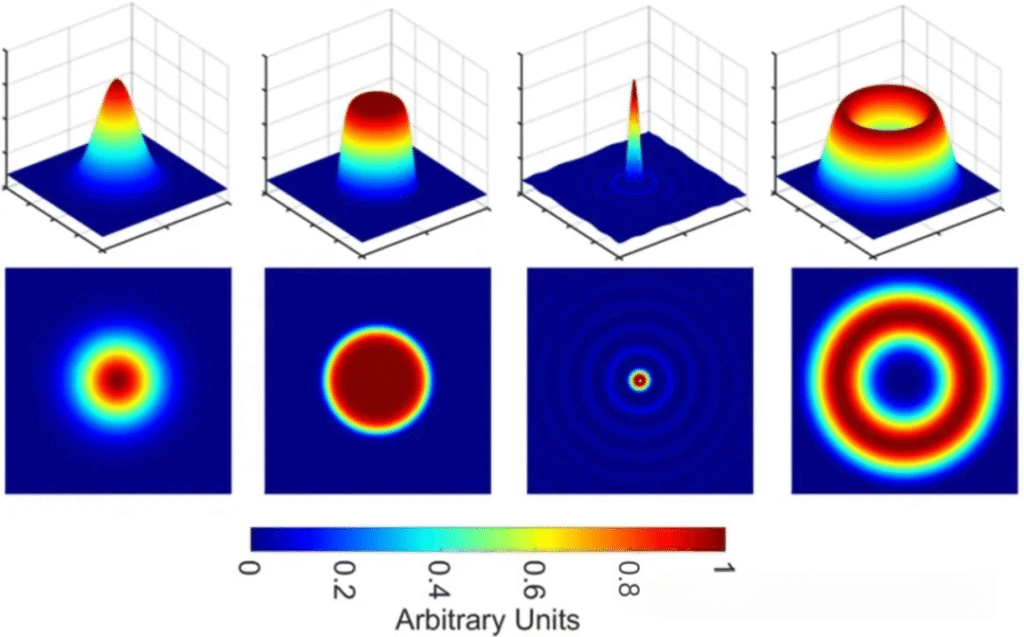

Energy Distribution of Gaussian, Top-Hat, Bessel, and Ring Beams

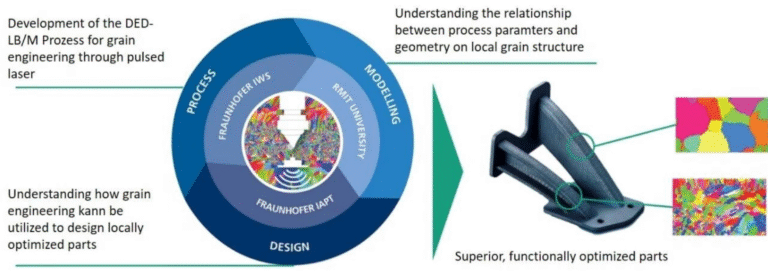

To overcome the drawbacks of Gaussian beams in L-PBF 3D printing, researchers are actively exploring beam-shaping technologies. For example, introducing beams with a top-hat or ring profile can deliver a more uniform temperature distribution, improve process stability, and significantly boost productivity. Experimental results show that beam shaping can reduce melt-pool turbulence and spattering, leading to higher part density and improved tensile performance. Moreover, beam shaping can enhance printing efficiency and reduce overall manufacturing costs.

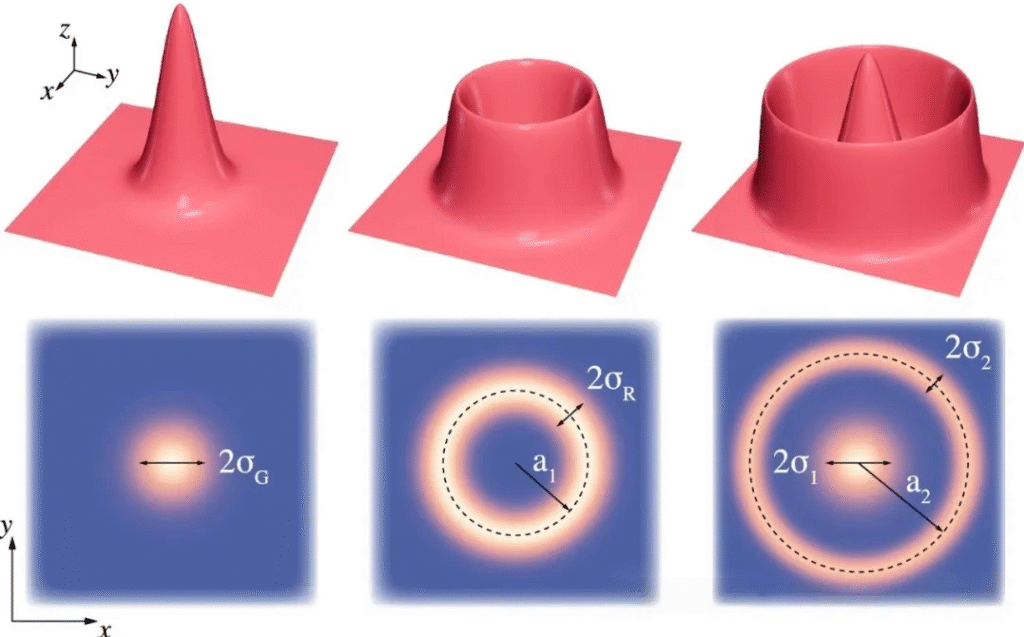

In laser powder bed fusion (L-PBF) 3D printing, a variety of beam-shaping profiles are used. These beam shapes are achieved through different optical elements and shaping methods to optimize thermal distribution during printing, thereby improving print quality and efficiency.

Elliptical Beams

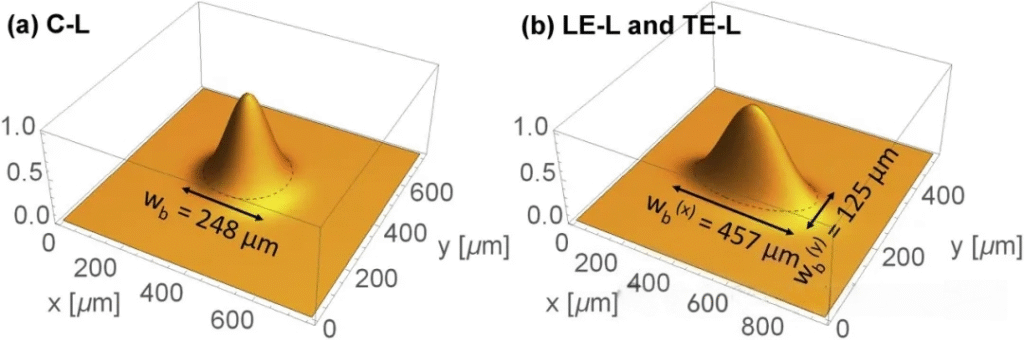

Elliptical beams are formed by reshaping a circular Gaussian beam and can be divided into two types: longitudinally elliptical and transversely elliptical. This means their intensity distribution is non-uniform along two axes. As a result, the heating effect and printing efficiency vary depending on the direction, which in turn affects the bonding strength between adjacent layers.

Numerical Fitting of Measured Spatial Intensity Distributions of Gaussian and Elliptical Beams

Compared with Gaussian beams, elliptical beams—especially transversely elliptical beams—exhibit lower energy gradients. This helps stabilize the melt pool, reduce spattering, and promote the formation of equiaxed grains and finer microstructures. However, the melt track height induced by elliptical beams is nearly equal to the powder layer thickness, which may affect the bonding strength between newly deposited powder layers and the previously solidified material.

Top-Hat Beams

Compared with Gaussian beams, top-hat beams deliver a much more uniform laser energy distribution on the work surface, which significantly reduces the thermal gradient inside the melt pool. Under these conditions, the melt pool is more likely to be heated in a conduction-dominated mode. In conduction mode, grains tend to grow epitaxially, making it easier to produce coarser grains.

The larger spot size of a top-hat beam greatly enhances the efficiency of laser-based printing, while its uniform energy profile helps conserve energy. Because of its uniform energy distribution, higher-density parts can be obtained even across a wide range of laser power settings.

Furthermore, melt-pool flow generated by a top-hat beam is smoother than that produced by a Gaussian beam, effectively suppressing the formation of vapor plumes and significantly improving the surface quality of the printed components. The perfectly uniform energy distribution of the top-hat beam also extends the melt-pool dwell time, which is beneficial for internal gas escape and overall process optimization.

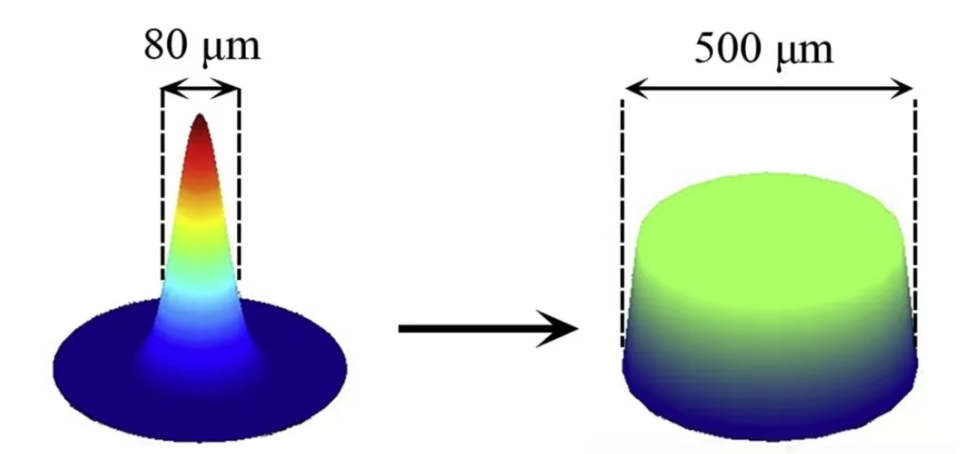

Transition from Gaussian to Top-Hat Laser Energy Intensity Distribution

Although top-hat beams offer clear advantages in forming a more ideal melt pool and improving processing efficiency, they are not without challenges. First, it is difficult to maintain a stable beam profile during propagation. Second, the uniform intensity distribution of a top-hat beam is primarily confined to the imaging plane or the vicinity of the focal point within the optical system.

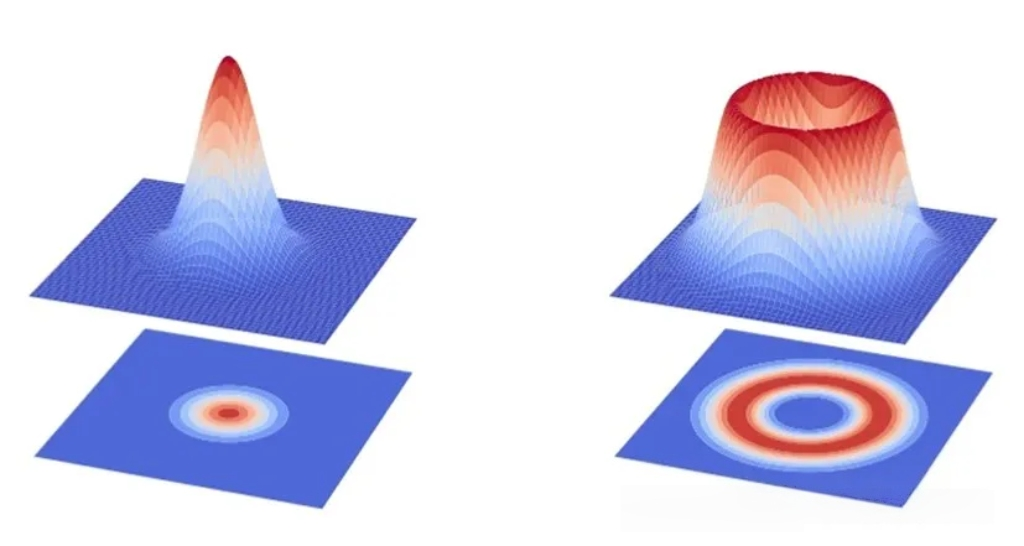

Bessel Beams

In laser powder bed fusion (L-PBF) technology, increasing the powder layer thickness is an effective strategy to significantly improve manufacturing efficiency. However, although increasing the laser energy density can deepen the melt pool produced by a Gaussian beam, it simultaneously introduces large energy gradients that lead to printing defects.

To address this challenge, researchers have turned their attention to Bessel beams. Their distinctive concentric-ring intensity distribution provides a promising approach for achieving greater melt depth, higher melt pool stability, and lower thermal gradients.

Bessel beams possess a propagation-invariant central core—i.e., a non-diffractive characteristic—as well as a greater depth of focus and a self-healing property. The self-healing ability means that after encountering obstacles along the propagation path, the beam can reconstruct itself, thereby mitigating the negative effects of spatter on part quality during the L-PBF process.

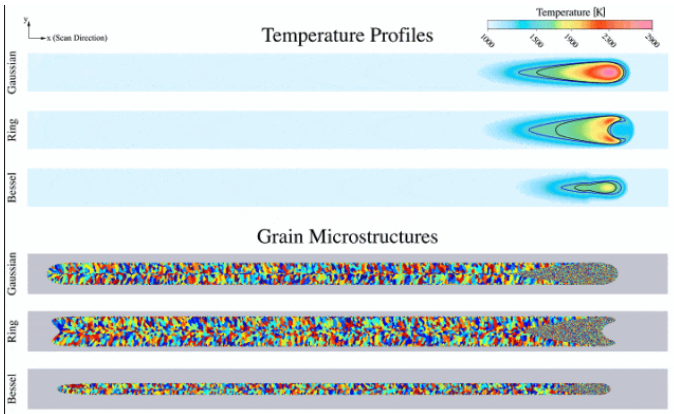

Further studies have shown that the central lobe of the Bessel beam facilitates deeper melt penetration, while its surrounding ring pattern effectively suppresses spattering and porosity formation. Compared with Gaussian beams, Bessel beams produce a more stable melt pool vapor plume angle during printing, reducing spatter, lack-of-fusion defects, and porosity, thereby improving part density and surface quality.

In terms of strength and ductility, parts fabricated with Bessel beams perform comparably to those produced with Gaussian beams, but they exhibit different trends as the incident energy density varies. Bessel beams are capable of producing denser parts across a wider range of process parameters and promote the formation of equiaxed grains within the melt pool, which contributes to improved overall part performance.

Overall, Bessel beams—thanks to their unique optical characteristics and superior performance in L-PBF—offer a promising solution for improving printing efficiency, process stability, and part quality.

Ring Beams

Ring beams exhibit a lower energy density at the center and higher intensity at the periphery, forming an annular intensity profile, and are sometimes referred to as “inverse Gaussian beams.” Compared with Gaussian beams, the lower laser intensity in the center of a ring beam produces a shallower melt pool, which results in a lower remelting rate of the previously deposited material, and in some cases, almost no remelting at all. Consequently, the interlayer bonding strength between metal layers is significantly weakened.

Comparison Between Gaussian Beams and Ring Beams

Unlike other laser beams that involve only a single heating and cooling cycle, the annular profile of an inverse Gaussian (ring) beam causes the melt pool to undergo two heating and cooling cycles, resulting in a lower temperature at the melt pool center compared to the surrounding annulus.

Studies have shown that replacing a Gaussian beam with a ring beam significantly reduces the width of the unconsolidated powder zone, thereby improving the overall quality of 3D-printed components. Furthermore, during printing with a ring beam, metal particles tend to escape toward the rear of the melt pool, in contrast to the forward-directed spatter observed when using Gaussian beams.

Simulation of Melt Pool Morphology under Gaussian, Ring, and Bessel Beams

The unique thermal field and melt pool characteristics of the ring beam have a significant impact on grain structure formation and defect generation. Some studies suggest that this beam profile creates a “buffer zone” around the melt pool, allowing high-pressure vapor to escape, thereby reducing spatter and porosity.

Other studies have observed that the arc-shaped cross-section at the top of the ring-beam-induced melt pool leads to the formation of ripple-like surface structures on the printed part. These ripples cause subsequent powder layers to have uneven thickness, resulting in non-uniform heat transfer in the powder bed and, consequently, more bonding defects and pores.

Furthermore, the ring beam has a pronounced influence on the grain structure of the printed component, enabling the formation of finer grains compared with those produced by a Gaussian beam.