Carnegie Mellon University has reported the development of a novel ceramic 3D printing process based on aerosol jet printing (3D-AJP), enabling the fabrication of high-performance ceramic materials with intricate microstructures. The technology utilizes a binder-free, support-free nanoscale printing method, achieving complex ceramic structures with a minimum feature size of 20 microns. After sintering, the printed parts demonstrate exceptionally low shrinkage (2–6%), significantly enhancing dimensional accuracy.

The research highlights the potential of this breakthrough in applications such as photocatalysis, biosensing, and microelectronic packaging, where high precision and material performance are critical.

In parallel, a miniature jet engine developed using advanced ceramic manufacturing has achieved a thrust of 160 kilograms (approx. 352 pounds), setting a new benchmark in its category. This success fills a crucial technological gap in the domestic field of turbojet engines and demonstrates China’s growing capabilities and innovation strength in high-end aerospace manufacturing.

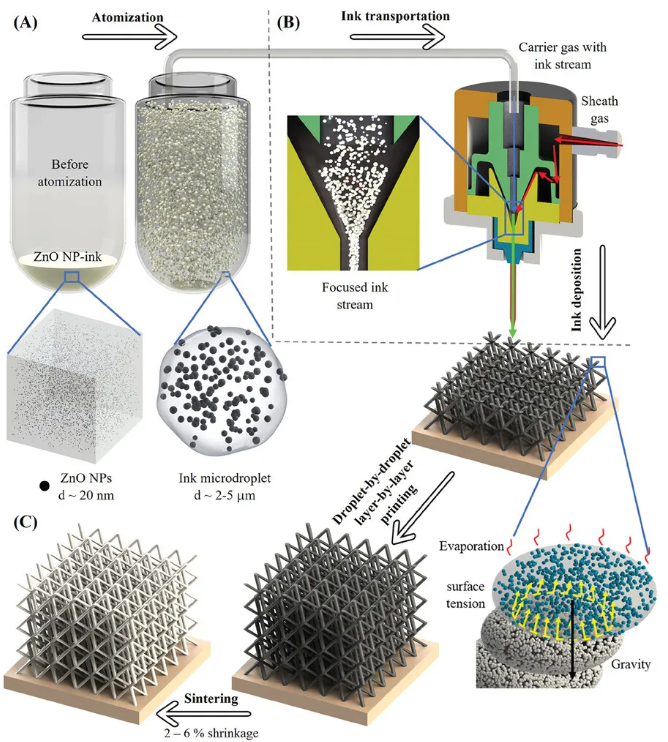

Schematic of 3D Aerosol Jet Printing (3D-AJP): Near-Zero Shrinkage Nano-Printing of Complex 3D Ceramic Microstructures

A) Using the ultrasonic atomizer in the AJ nanoparticle printer, ZnO nanoparticle-based ink is aerosolized. The inset shows nanoparticles in the ink reservoir (≈20 nm in diameter) as well as a single droplet.

B) The generated aerosol is transported through a tubing system by an inert carrier gas to the deposition nozzle. The inset illustrates the sheath-gas-focused ink stream loosely directed onto the substrate.

C) Rapid, droplet-by-droplet freeform printing without the need for support structures. The inset demonstrates the mechanism that enables inclined structures to be built without auxiliary support. After sintering, extremely low shrinkage is observed, validating its near-net-shape manufacturing capability.

At the core of 3D-AJP is the precise deposition of nanoparticle inks to construct intricate three-dimensional microstructures. By employing nearly binder-free inks, the process avoids the high shrinkage and structural defects that typically result from binder removal in conventional ceramic manufacturing.

This technique achieves a minimum feature size of 20 microns, enabling the fabrication of complex geometries such as micropillars, helices, and lattices with aspect ratios as high as 30:1. Moreover, it supports multi-material integration, allowing different ceramic materials—such as zinc oxide (ZnO), titanium dioxide (TiO₂), and zirconia (ZrO₂)—to be seamlessly combined within a single printed structure.

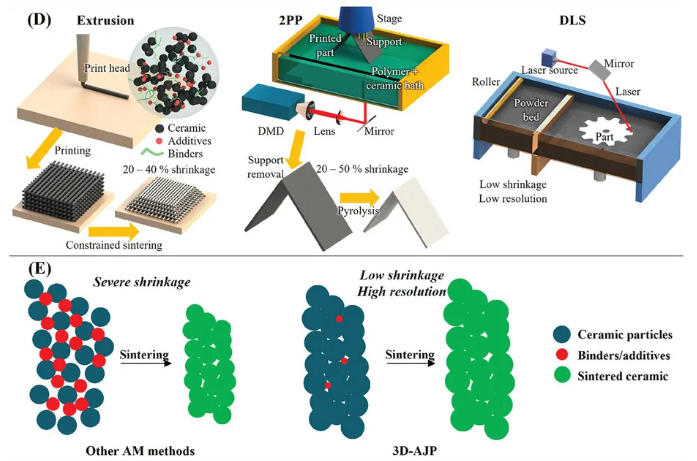

Ceramics Fabricated by Other 3D Printing Techniques (such as Extrusion Printing, 2PP, and DLS). Shown are precursor inks with high binder content (left) and minimal binder content (right) used in ceramic manufacturing.

The post-sintering linear shrinkage of this new method is only 2–6%, significantly lower than that of conventional techniques (e.g., 15–43% in typical 3D printing processes). In addition, 3D-AJP technology enables the rapid fabrication of complex ceramic structures without the need for complicated post-processing steps.

This study demonstrates the broad application potential of 3D-AJP across multiple fields.

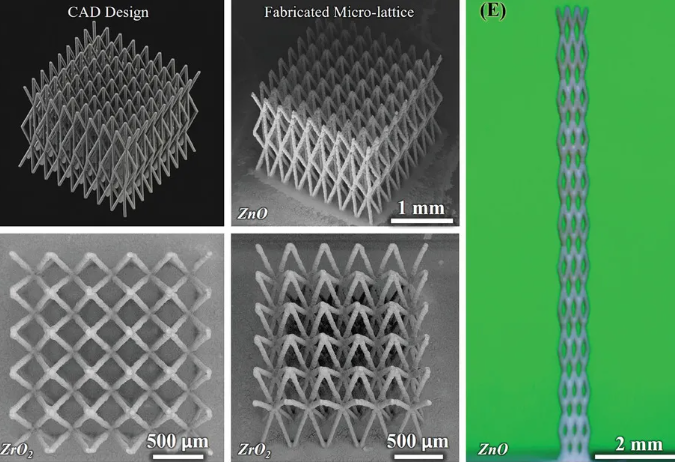

Comparison of CAD Designs and Fabricated Zinc Oxide (ZnO) Microlattices via 3D Aerosol Jet Printing (3D-AJP). Optical image of a high-aspect-ratio microlattice (height: 1 cm, width: 600 μm). Top-view (left) and tilted SEM images (right) of microlattices made from a different ceramic material, zirconia (ZrO₂).

In the field of photocatalysis, researchers fabricated ZnO microlattice structures using 3D-AJP and applied them to the photocatalytic degradation of methyl orange dye. Results showed that, compared with conventional bulk ZnO, the 3D-AJP-fabricated ZnO microlattices exhibited a 400% improvement in photocatalytic efficiency, demonstrating remarkable performance enhancement.

In the field of biosensing, a sensor manufactured using 3D-AJP was developed to detect the breast cancer biomarker Her2. The sensor achieved ultrafast detection within 22 seconds and a detection limit as low as 0.0193 femtomolar (fM), highlighting its exceptional sensitivity.

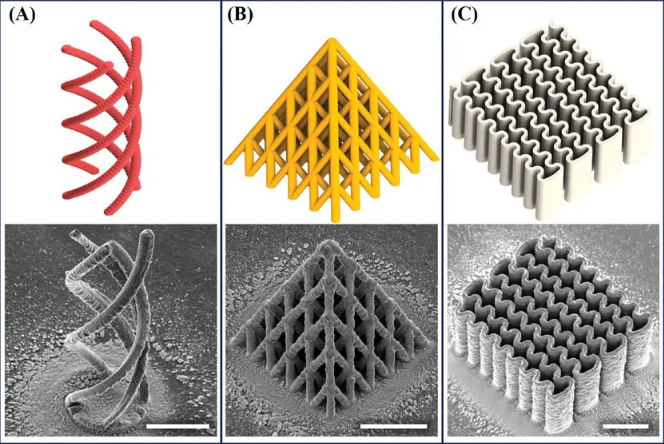

Complex Single- and Dual-Material Ceramic Microstructures Fabricated via Aerosol Jet Nano-Printing.

A) CAD design (top) and SEM image (bottom) of a multi-helix microstructure.

B) CAD design (top) and SEM image (bottom) of a pyramid-shaped microlattice.

C) CAD design (top) and SEM image (bottom) of a ZnO wavy micro-wall. Scale bars: 500 μm.

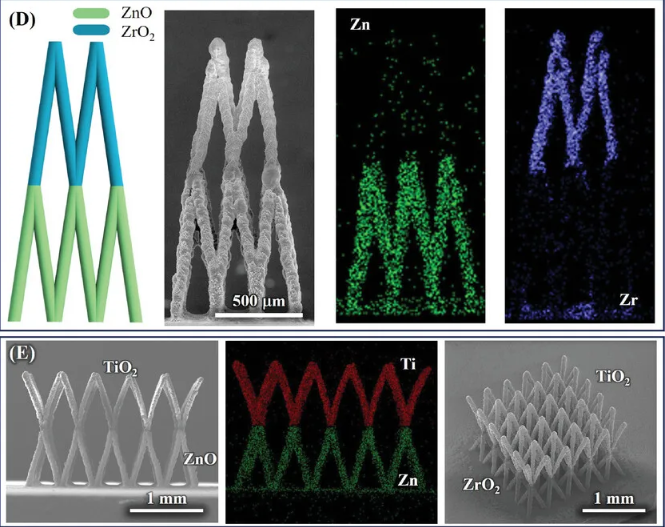

D) Printed dual-material pyramid microlattice (left) and EDX analysis confirming the presence of zirconium (Zr) and zinc (Zn) in different printed layers (right).

E) Additional dual-material microlattices, including TiO₂ (top) and ZnO (bottom), with EDX analysis verifying the material composition. Another dual-material structure consisting of TiO₂ (top) and ZrO₂ (bottom) is also shown.

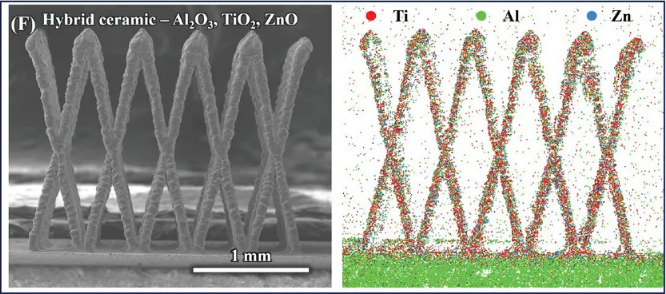

F) Mixed ceramic microlattice incorporating Al₂O₃, TiO₂, and ZnO, with EDX analysis demonstrating uniform distribution of titanium (Ti), aluminum (Al), and zinc (Zn) within a single lattice.

Beyond single-material structures, 3D-AJP technology demonstrates the capability to integrate multiple ceramics—such as ZnO, TiO₂, and ZrO₂—into a single architecture. This opens new opportunities for fabricating high-performance catalytic, sensing, and optoelectronic devices.

Overall, the binder-free nanoscale printing process of 3D-AJP enables high-precision fabrication of complex ceramic microstructures with exceptionally low post-sintering shrinkage. The technology not only shows significant performance enhancements in photocatalysis and biosensing, but also introduces new possibilities for multi-material composite structures. With its scalability and versatility, 3D-AJP holds promise for broad applications in microelectronic packaging, structural materials, biomedical sensing, thermal barrier coatings, and filtration technologies, paving a new direction for the manufacturing of high-performance ceramics.