In 2018, Bugatti made headlines by unveiling the world’s first 3D-printed titanium brake caliper. This groundbreaking innovation combined exceptional strength with remarkable lightness, setting a new benchmark in automotive engineering. Engineered to endure extreme levels of stress, the component not only enhances safety but also ensures peak performance on the track. The introduction of this technology marks a significant milestone in the integration of additive manufacturing into high-performance automotive design.

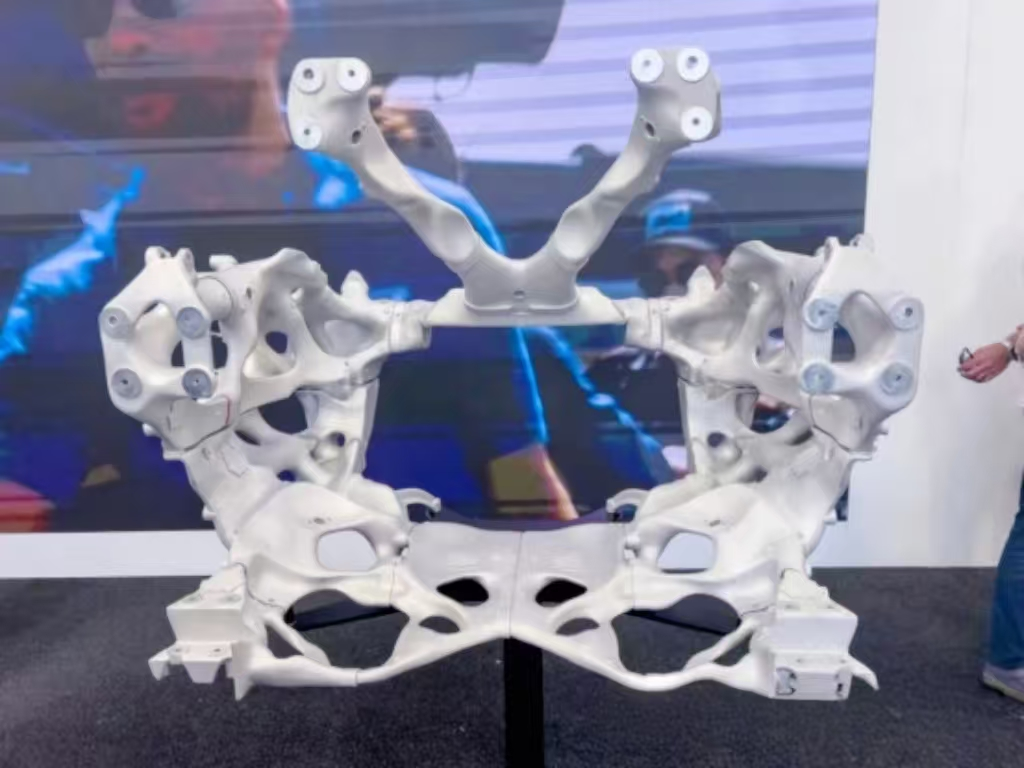

In 2024, to develop its latest hypercar, the Bugatti Tourbillon, the French manufacturer announced a strategic partnership with U.S.-based Divergent, a pioneer in end-to-end hardware and software production systems for industrial digital manufacturing. Through this collaboration, Divergent’s Adaptive Production System (DAPS™) was applied to the design, additive manufacturing, and assembly of chassis and suspension components. Leveraging Divergent’s fully digitalized vehicle design and production methodology, Bugatti was able to engineer more efficient geometries for the chassis, achieving significant weight reduction while enhancing overall vehicle performance.

In April 2020, Porsche unveiled 3D-printed pistons designed for the high-performance engine of its most powerful 911 model, the Porsche 911 GT2 RS. The innovation aimed to reduce piston weight and enhance overall engine efficiency.

Manufactured using a laser powder bed fusion process, the pistons integrated a closed cooling channel at their base—an engineering feat impossible to achieve with traditional subtractive methods. This intricate cooling channel reduced the thermal load around the piston rings by 20°C. Compared to conventionally produced components, the 3D-printed pistons delivered higher rigidity while being 10% lighter. As a result, engine speeds increased, combustion efficiency improved, and horsepower was boosted by up to 30 hp.

During quality assurance, the 3D-printed pistons successfully passed a rigorous 200-hour endurance test on the engine test bench, proving their durability and reliability for high-performance applications.

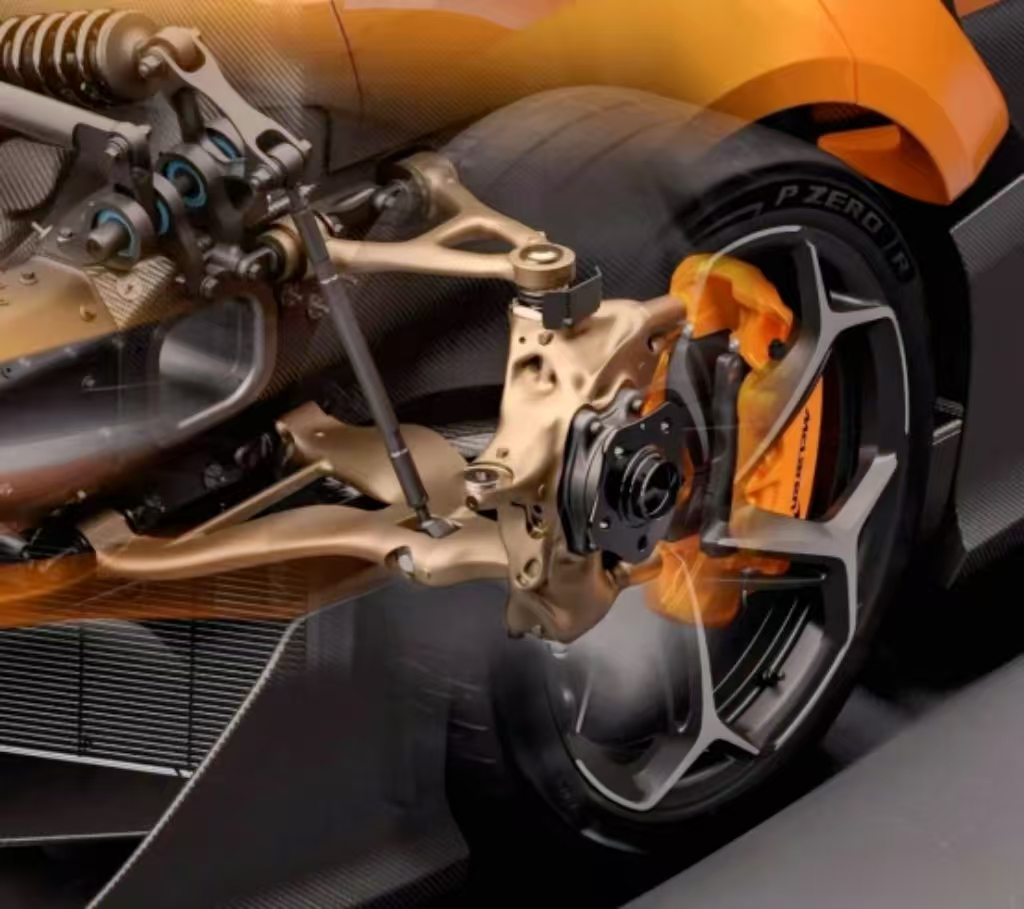

In 2024, Ferrari introduced additively manufactured structural components for the first time in its latest hypercar, the F80. The F80’s independent suspension system features a double-wishbone configuration, active inboard dampers, and suspension arms produced using additive manufacturing.

The Italian automaker leveraged its extensive experience in motorsport—particularly Formula 1—by applying advanced metal additive manufacturing techniques to produce critical components. Originally developed and fine-tuned for racing performance, these technologies are now integrated into road-going models such as the F80.

This solution offers numerous advantages, including optimized geometry, more precise wheel control, reduced unsprung mass, the elimination of anti-roll bars, and the introduction of a dedicated camber correction function. The system successfully balances two seemingly contradictory requirements: delivering stability on the track, where minimizing ride-height variation is crucial, while also providing flexibility to absorb road irregularities during everyday driving. As a result, the F80 delivers outstanding handling on the road while ensuring optimal downforce management under all conditions.

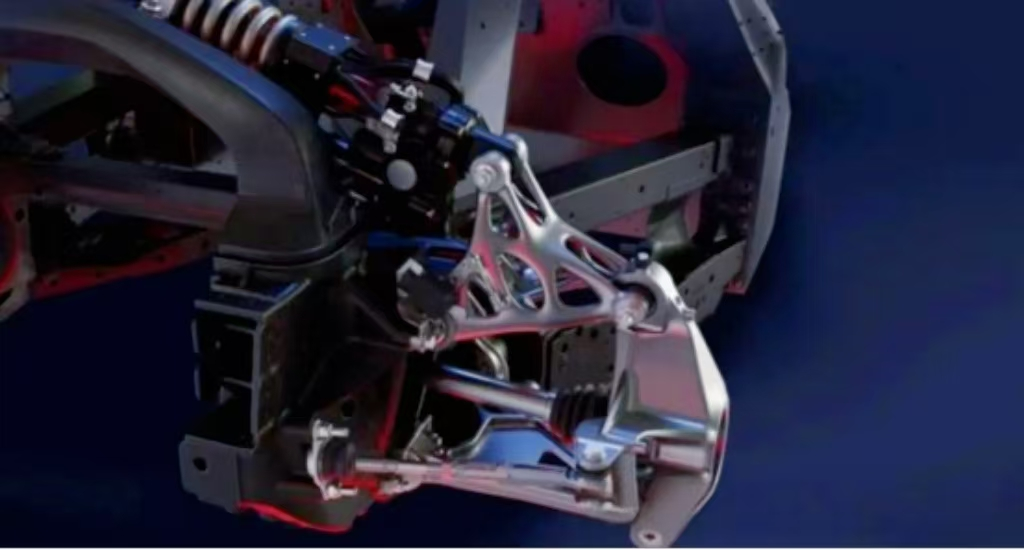

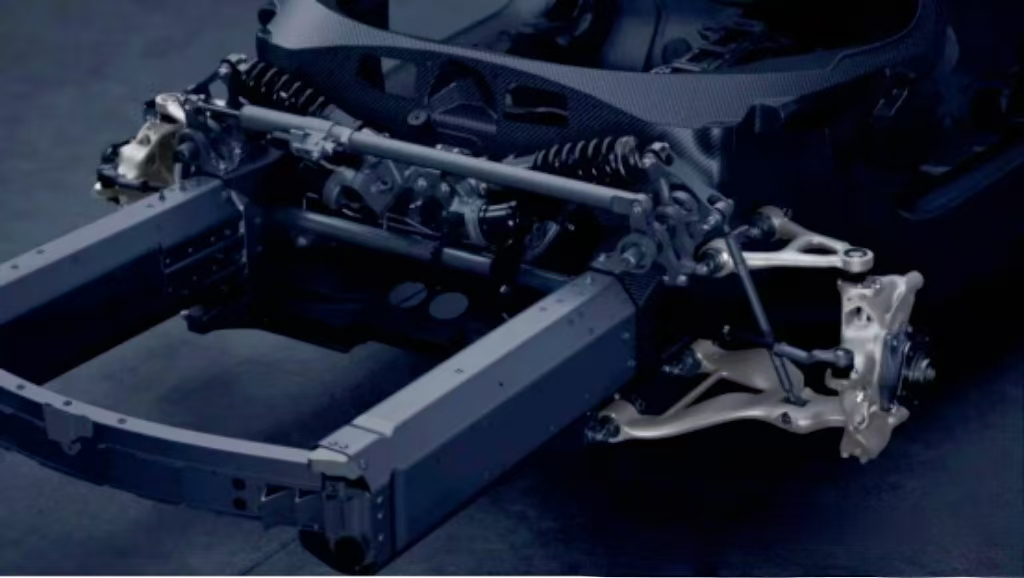

McLaren Automotive has partnered with Divergent to develop advanced suspension hardware for its latest hypercar, the McLaren W1. The new W1 is equipped with a Formula 1–inspired front suspension system, mounted directly onto its Aerocell carbon-fiber monocoque.

Leveraging Divergent’s state-of-the-art additive manufacturing technologies, McLaren has created a highly efficient and structurally complex suspension system designed for maximum durability and rigidity. Key components include the upper front wishbone, aerodynamically optimized lower wishbone, and front bracket—all integral to the hypercar’s performance.

Among these, the visible upper front wishbone stands out as a critical 3D-printed part produced by Divergent, underscoring the transformative role of additive manufacturing in shaping the next generation of high-performance automotive engineering.

The company’s innovative design and manufacturing approach has enabled McLaren engineers to rapidly iterate and accelerate the development of revolutionary structural suspension components, directly contributing to the outstanding performance and driver engagement of the W1.

“We are delighted to collaborate with Divergent, a company that shares McLaren’s relentless commitment to innovation in manufacturing and engineering. This cutting-edge technology allows us to develop more advanced suspension architectures in the McLaren W1, enhancing the driving experience for our customers and supporting McLaren’s mission to continuously push the boundaries of performance,” said Michael Leiters, CEO of McLaren Automotive.

Current Challenges and Limitations of Additive Manufacturing in High-Performance Automotive Applications

The applications of additive manufacturing (AM) in high-performance vehicles extend far beyond the cases highlighted above. A broader analysis reveals that most of these use cases are centered on the design and additive production of specific components. While these examples demonstrate how AM can meet extremely high performance and durability requirements, a fundamental question remains: what factors are preventing the broader adoption of this technology across the entire automotive design and manufacturing process?

Key Challenges

High Costs

The specialized equipment and materials required—such as advanced alloys or high-performance polymers—remain expensive, limiting their application in mass-market vehicles with lower profit margins. In addition, durable and recyclable materials often cost more than their traditional counterparts.

Production Time

While additive manufacturing is efficient for prototyping or small-batch production, conventional methods like molding or stamping remain far more cost-effective for producing millions of units intended for the mass market.

Production Capacity

Current 3D printing systems cannot yet match the throughput of highly automated production lines, creating a barrier to scalability.

Durability and Reliability

Certain 3D-printed components still need to prove their long-term performance and resilience, particularly for vehicles intended for everyday use.

Certification and Standards

In mass-production vehicles, every component must meet strict quality, safety, and performance requirements. Printed parts still require rigorous certification to ensure compliance.

Integration into Existing Production Lines

Incorporating AM into traditional industrial processes requires substantial investment, often demanding significant adjustments or a complete rethinking of existing manufacturing infrastructure.

Conclusion

Although additive manufacturing is currently limited to specific applications in high-performance automobiles, it is gradually becoming a catalyst for innovation. It enables manufacturers to push the boundaries of what is possible—whether in weight reduction, customized design, or accelerated development cycles. However, for this revolution to transition from a high-tech tool to an industry standard, obstacles remain, particularly in terms of cost, production speed, and integration with traditional processes.

In the near future, a supercar entirely designed using additive manufacturing technology—from chassis and body to engine and its smallest components—may no longer be out of reach. A decade ago, such a project seemed unattainable, but with advancements in industry processes, it is becoming a reality. If professionals continue to overcome current challenges, fully 3D-printed cars on the road will be only a matter of time, marking the dawn of a new era in the automotive industry.