Polymaker Showcases Breakthrough in 3D Printing Materials, Unlocking New Possibilities for High-Quality Additive Manufacturing

The quality of 3D printing materials is one of the key factors that determines the success and reliability of the entire printing process. In many cases, failed prints can be traced back to poor-quality filaments. Choosing high-performance materials not only reduces failures but also ensures smoother workflows and higher-quality outputs.

In response to these industry challenges, many material manufacturers are bringing forward their own innovations, with some focusing on reducing costs while others aim to make 3D printing more accessible. Among them, Polymaker has stood out, leaving a strong impression through its commitment to providing high-quality materials and hardware that make 3D printing easier, more user-friendly, and more efficient. The company’s efforts significantly reduce print failures caused by material issues and elevate the overall standard of finished products.

Polymaker specializes in the research and development of FDM 3D printing materials, introducing a comprehensive portfolio of five key product lines:

Panchroma™ series

Fiberon™ series

Polymaker’s essential materials collection

PolyCore™ pellets

PolyDryer™ professional drying equipment

These solutions cater to a wide range of applications, from industrial product design and end-use manufacturing to healthcare and maker communities.

One highlight is the Panchroma™ series, also branded as the “Palette,” developed specifically to meet aesthetic demands. This line offers more than 170 color options and 22 unique surface finishes, giving designers unparalleled creative freedom. Users can choose from matte, silk, glow-in-the-dark, gradient, and other effects to achieve exceptional results. At trade shows, Polymaker showcased a striking “color palette wall” filled with products in different hues and textures, creating a powerful visual impact and underlining the brand’s dedication to material diversity and innovation.

With its growing ecosystem of advanced materials and equipment, Polymaker is redefining the role of filament quality in additive manufacturing—making 3D printing not only more reliable but also more inspiring for industries and creators alike.

Polymaker Showcases Versatile Base Material Series, Expanding 3D Printing Applications

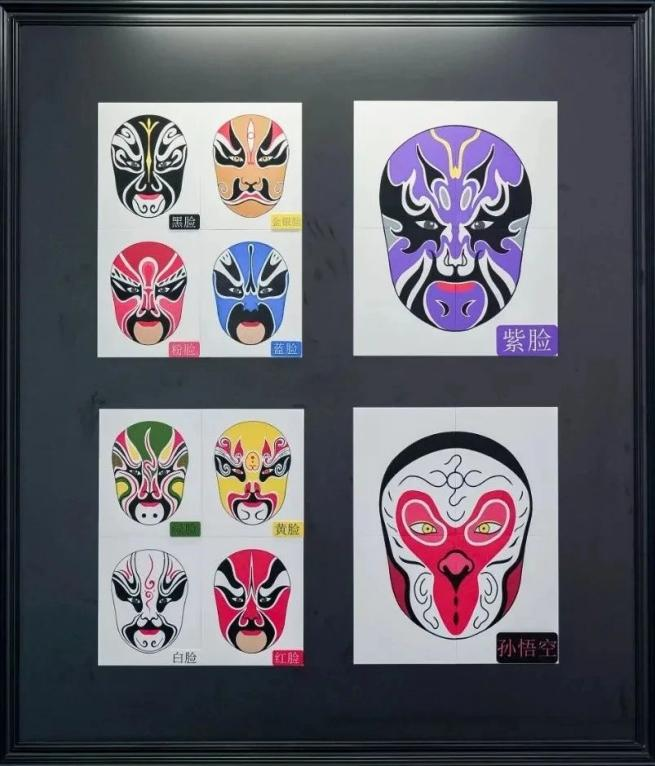

Peking Opera Masks

At the exhibition, alongside its innovative aesthetic and high-performance product lines, Polymaker highlighted its Base Material Series, which includes widely used FDM 3D printing materials such as ABS and PLA.

Among them, ABS is recognized for its excellent mechanical properties and heat resistance, making it a staple in both industrial and consumer-grade applications. A PC material was also showcased on site, demonstrating outstanding strength and reliable printability — an ideal choice for demanding applications such as drone frames.

In addition, Polymaker introduced a new support material designed specifically to provide structural support during the printing process. Once printing is completed, this material can be easily removed, significantly improving post-processing efficiency and user convenience.

With these new offerings, Polymaker reinforces its expertise in diverse 3D printing material development while further driving the adoption of additive manufacturing across industrial production and innovative applications.

Exhibit highlight: a drone frame 3D printed with Polymaker’s PC material, showcasing its strength and printability.

Showcased prosthetic printed with TPU 90 filament, highlighting its exceptional durability for long-term use

A highlight of this product line is its application in the medical field. Polymaker showcased a prosthetic limb and an orthosis at the exhibition. The prosthetic, produced with the company’s TPU 90 filament, delivers a groundbreaking wearing experience and performance compared to both traditional solutions and those made with other 3D printing materials. While 3D-printed prosthetics can be designed smaller and lighter, the layered manufacturing process often raises concerns about potential breakage. However, this TPU 90-printed prosthetic has been used for over six months, demonstrating excellent interlayer adhesion and long-term durability. In addition, the material’s remarkable flexibility ensures sufficient support and comfort for users, setting a new benchmark for medical 3D printing applications.

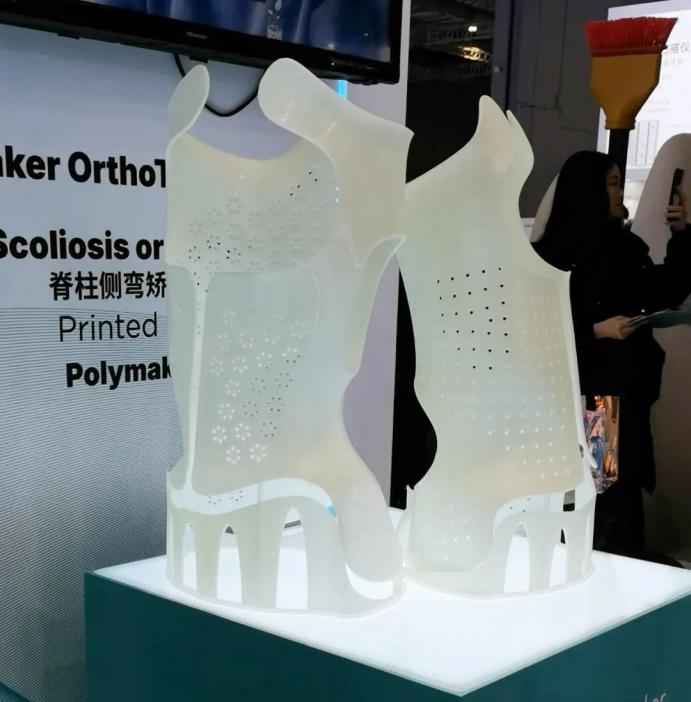

OrthoTough™ 1000 Medical-Grade Material

Another highlight is OrthoTough™ 1000, a medical-grade material developed by Polymaker specifically for producing spinal orthoses for scoliosis patients. Orthotic devices 3D-printed with this material demonstrate exceptional durability and stability, even under frequent opening and closing, significantly reducing the risk of damage.

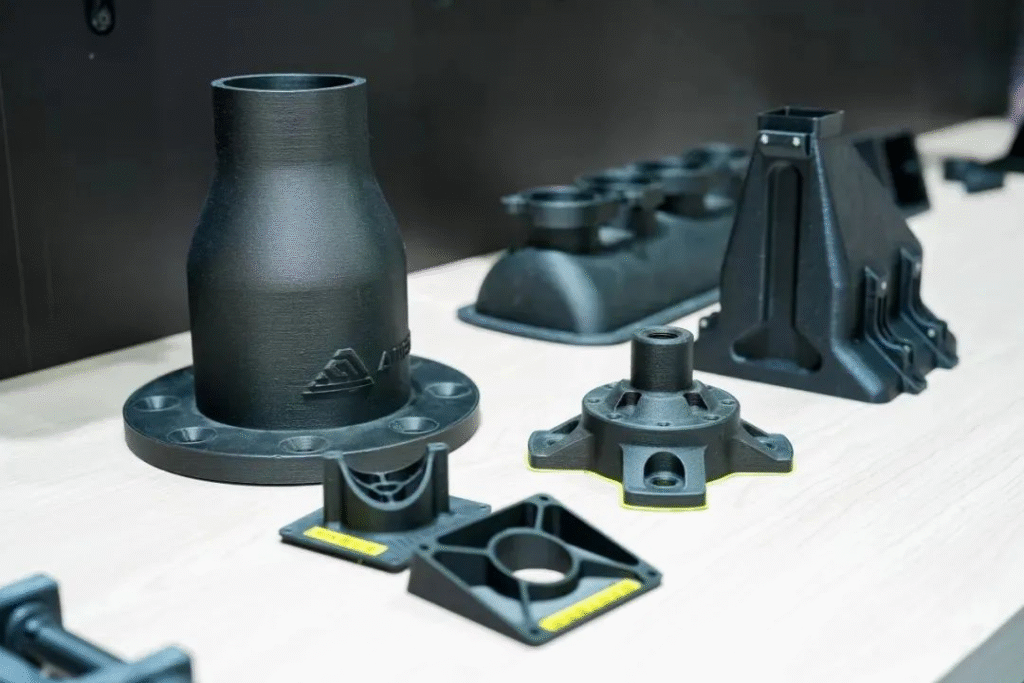

Polymaker also unveiled a portfolio of high-performance materials designed to meet the rigorous demands of specialized industries. The showcase included carbon fiber– and glass fiber–reinforced PPS and PA grades, along with advanced anti-static materials. For example, the carbon fiber–reinforced PPS offers outstanding thermal resistance, with a glass transition temperature reaching up to 252 °C, alongside impressive modulus strength.

In addition, nylon composites reinforced with either carbon fiber or glass fiber—such as PA6 CF/GF and PA12 CF/GF—provide tailored mechanical properties for different applications. Meanwhile, Polymaker’s anti-static materials offer effective electrostatic discharge protection, making them ideal for electronic housings and ESD-sensitive environments.

High-performance composite material series for direct manufacturing of end-use parts.