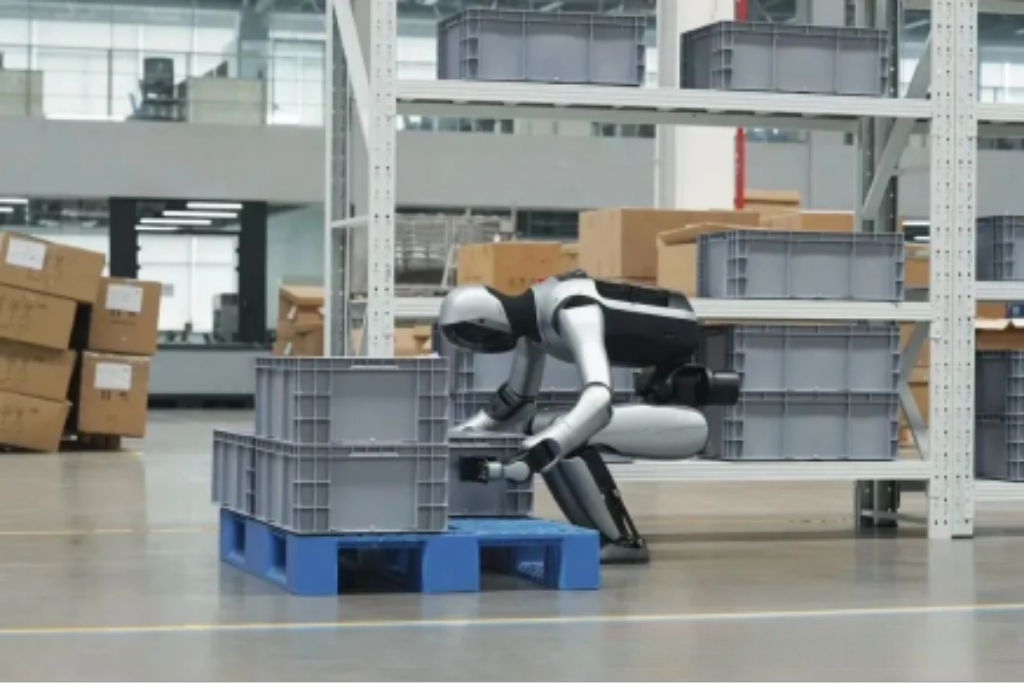

On July 25th, UBTECH, one of the earliest companies to enter the humanoid robot industry, announced the launch of its industrial humanoid robot, Walker S2, designed for smart manufacturing scenarios.

This robot integrates a dexterous hand and a bionic arm, supporting high-level actions such as autonomous battery swapping. According to 3D printing technology references, UBTECH employed 3D printing technology in the development and manufacturing process of this robot to achieve lightweight design and reduce production costs.

The World’s First Humanoid Robot Capable of Autonomous Battery Swapping

Autonomous Battery Swapping is a key reason why the robot has garnered widespread attention. The humanoid robot release highlights that this technology operates without human intervention, and, when combined with group collaboration technology, it enables 24/7 operations within manufacturing environments. This breakthrough provides a transformative solution to the industry’s pain points in implementing humanoid robots in industrial scenarios.

3D Printing Technology Empowers Autonomous Battery Swapping

To achieve the flexibility required for autonomous battery swapping, the Walker S2 features a waist with a rotation freedom of ±162°. Despite the increased degrees of freedom, the Walker S2’s weight has been reduced from 76kg (in the Walker S1) to 70kg through the use of 3D printing technology and new composite materials. The structure is more compact, and the agility of the robot has been enhanced, providing a solid hardware foundation for precise battery swapping.

Due to the need for the robot to rotate its waist during product handling and battery swapping, the load on the robot’s body structure is significant, raising higher demands for lightweight design and the strength of structural components.

The Walker S2 features a unique structural component, independently designed and developed by UBTECH. This innovation overcomes structural design and manufacturing challenges of certain components, ensuring the strength, durability, and longevity of the waist joint. Through breakthroughs in material science, the design not only ensures the robot can support loads of several dozen kilograms but also achieves a lightweight structure, guaranteeing the robot’s overall stability during the battery swapping process.

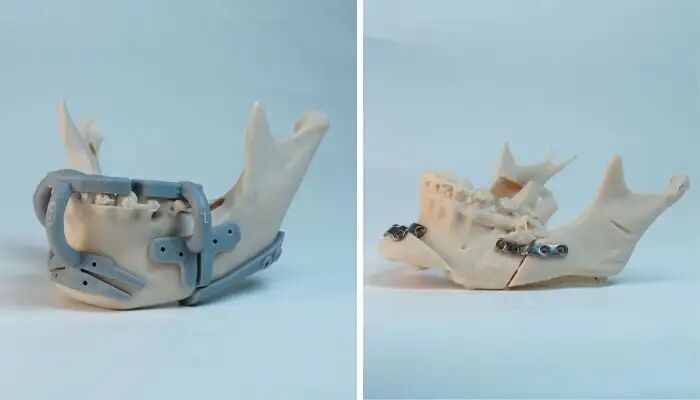

Some organizations have pointed out that the printing of large structural components is far more challenging than that of smaller parts. This is because traditional 3D printing technologies often face issues such as uneven stress distribution and insufficient precision when printing large-sized components, leading to parts that fail to meet strength requirements.

From a structural design perspective, UBTECH’s component may have leveraged topology optimization algorithms to reduce material usage in non-stress areas. This approach allows for on-demand material allocation, achieving both the goal of lightweight design and meeting the strength requirements for industrial scenarios.

Large orders undoubtedly involve the mass production of robots, signaling that the humanoid robot industry has reached the threshold of mass production.

The first key factor behind mass production is cost. In the face of cost thresholds often reaching hundreds of thousands, UBTECH has implemented several cost-reduction strategies in the development of the Walker S2, one of which is the adoption of 3D printing technology.

Narrow Channel Sorting

The benefits brought by the application of 3D printing technology in the robotics industry are strikingly similar to those in the fighter jet industry, in that they provide compound benefits. This process enables the manufacturing of complex robotic structures that cannot be produced using other methods, such as topology-optimized and lattice structures. These structures not only enhance the strength and performance of robotic components but also reduce the overall weight of the robot. Furthermore, the reduction in overall weight extends the robot’s battery life, allowing for more complex and diverse movements. In addition, 3D printing technology enables one-to-one customization, making it adaptable to a wide range of application scenarios.

Botland Exhibits at the World Robotics Conference

Most humanoid robots need to be recharged after 3 to 4 hours of operation, requiring approximately 40 minutes of charging. However, the production pace in factories is continuous, and even a 1-hour downtime can severely disrupt the production line rhythm. As the world’s first humanoid robot capable of autonomous battery swapping, the Walker S2 will bring new possibilities to the industrial application of humanoid robots.

Full-Space Range Handling

The 2025 World Robotics Conference will be held from August 8 to 12, 2025, in Beijing. The event is jointly organized by the Chinese Institute of Electronics and the World Robotics Cooperation Organization, with the theme “Making Robots Smarter, Making Bodies Smarter.” Over 200 domestic and international robotics companies will showcase more than 1,500 exhibits, including more than 100 new product launches.

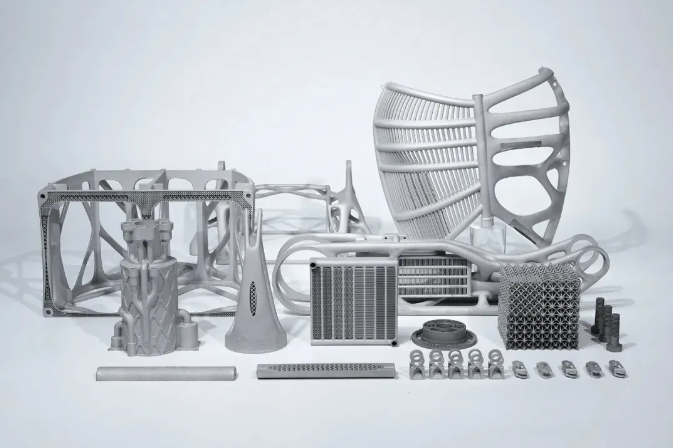

On-site MT400M printing will demonstrate the integrated forming of robot body parts via live broadcast. The MT170 and MT280 series metal 3D printing equipment are set to drive the intelligent manufacturing upgrade in the robotics industry.

MT-TC4 titanium alloy powder, MT-AlSi10Mg aluminum alloy powder, and MT-304L/316L steel alloy powders are providing innovative materials for the robotics industry.

The exhibition also showcased 3D-printed structural components of humanoid robots, including the chest, arms, thighs, and calves, providing new ideas for structural innovation and manufacturing breakthroughs in the robotics industry.

There is no doubt that 3D printing technology empowers the robotics industry. Through its innovative applications in industrial humanoid robots, 3D printing has not only enhanced product performance and efficiency but also accelerated the transition of humanoid robots from the laboratory to commercial deployment. In the future, with further integration of 3D printing technology, artificial intelligence, and materials science, the robotics industry is poised to achieve even more breakthroughs in the field of intelligent manufacturing.