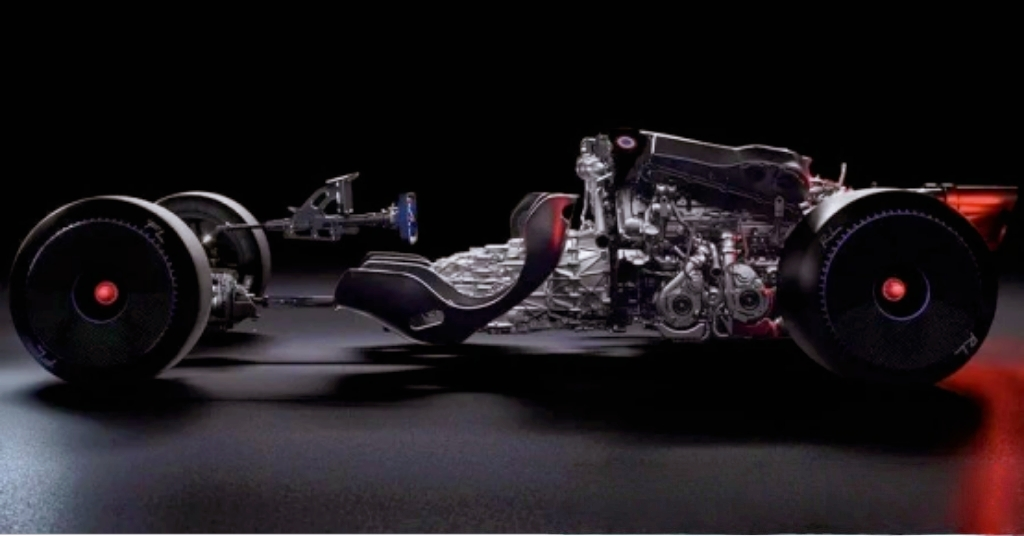

In the field of high-performance automobiles, manufacturers leverage the flexibility and precision of additive manufacturing to push the boundaries of performance, efficiency, and customization. From engine components to aerodynamic elements, this approach addresses various technical challenges while reducing development time and lowering costs. The following discussion will explore the applications of additive manufacturing in high-performance vehicles, as well as the challenges and limitations faced in this niche sector.

What is a High-Performance Automobile?

A high-performance automobile refers to a vehicle designed to deliver exceptional power, speed, acceleration, handling, and technical precision. These vehicles often come from renowned brands such as Ferrari, Lamborghini, or Bugatti, encompassing both sports cars and race cars used in Formula 1 or endurance competitions.

Such models are typically equipped with the latest engine technologies, advanced aerodynamics, and lightweight materials, with a strong emphasis on pure performance and driving experience. Their design demands extremely high precision, making the integration of technologies such as additive manufacturing particularly significant.

Additive Manufacturing in the Automotive Industry: Key Facts

In the automotive sector, manufacturers initially adopted additive manufacturing (AM) technologies to produce complex prototype parts at lower costs and with shorter lead times. In recent years, AM has evolved into an indispensable tool for manufacturing high-performance automotive components.

Currently, the relatively low production volume of additive manufacturing limits its scalability for mass production. However, in motorsport applications such as Formula 1, where large-scale manufacturing is not required, AM proves to be an ideal solution. Formula 1 teams build only two race cars per season, and given the need for rapid iteration throughout the development process, it is no surprise that additive manufacturing has become widely adopted by engineering teams in this field.

Additive Manufacturing in Formula 1: A Strategic Application

In Formula 1 racing, additive manufacturing (AM) plays a critical role in delivering performance, innovation, and responsiveness. Below are the key applications of AM in this elite field:

Rapid Prototyping and Accelerated Development

Teams use additive manufacturing to quickly create prototypes of complex parts, enabling them to test multiple variations in a wind tunnel or simulator within just a few days. This significantly shortens the time between design and validation.

Production of Functional Components

Several 3D-printed parts are directly integrated into the race car, such as:

Cooling ducts: Designed to optimize airflow and maintain ideal temperatures.

Aerodynamic components: Custom deflectors or ducts tailored for specific circuit requirements.

Lightweight brackets and fixtures: Manufactured from reinforced polymers or metals to reduce the car’s overall weight.

On-Site Manufacturing

Some teams bring 3D printers directly to the paddock, allowing them to produce parts on-site. This enables record-speed replacement or modification of components during race weekends.

Wind Tunnel Testing

Scaled 3D-printed models are used to experiment with aerodynamic concepts before applying them to full-scale cars.

Mercedes-AMG Petronas F1 Team, Red Bull Racing, and McLaren are among the teams that have adopted these practices to maximize performance and drive continuous innovation.

The most widely used technologies in this field include stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM). Each of these offers distinct advantages in terms of accuracy, production time, and material selection.

Advantages of 3D-Printed Components in High-Performance Cars

Interest in additive manufacturing within the high-performance automotive sector continues to grow, largely due to several key benefits that you may have already observed in other applications:

Lightweight Design and Material Optimization

Additive manufacturing enables the creation of complex structures, such as honeycomb geometries, that reduce weight while maintaining high mechanical strength. The result: lighter vehicles, enhanced performance, and lower energy consumption.

Customization and Personalization

AM allows the production of unique, tailor-made parts to meet specific requirements. For racing teams or luxury car manufacturers, this level of customization represents a major advantage.

Cost and Time Reduction

Unlike traditional methods, which often require expensive molds and long production lead times, additive manufacturing can directly produce components within just a few hours.

Rapid Prototyping and Design Innovation

Teams can iterate and test different design variations quickly, significantly accelerating the innovation cycle.

Materials Used in Additive Manufacturing for High-Performance Cars

In high-performance automotive applications, the choice of materials for additive manufacturing depends on their lightweight characteristics, strength, and ability to withstand extreme conditions:

Metal Alloys

Titanium: Lightweight, corrosion-resistant, and heat-resistant. Ideal for components such as brake calipers or engine parts.

Aluminum: Used for lightweight parts requiring good thermal conductivity, such as radiators or support structures.

Nickel-based alloys: Applied in areas exposed to extremely high temperatures, including exhaust systems or turbine components.

Advanced Polymers

PEEK (Polyether ether ketone): Heat-resistant, chemically resistant, and wear-resistant. Used for lightweight structural parts in the engine bay.

Reinforced Nylon (with carbon or glass fibers): High mechanical strength while remaining lightweight, making it ideal for aerodynamic components or technical brackets.

Polycarbonate (PC): Used in applications requiring transparency, durability, and impact resistance.

Composites

Carbon fiber-reinforced materials: Widely used for fairings, ducts, or chassis mounts, offering outstanding stiffness combined with lightweight properties.

Technical Ceramics: Less common, but 3D-printed ceramics are sometimes used for components exposed to extreme heat or corrosion, such as seals or thermal shields.

Prototype-Specific Materials: For rapid prototyping, plastics such as PLA or ABS may be used, though they are generally unsuitable for final high-performance applications.