After visiting several large factories with dozens or even hundreds of metal 3D printers, plant managers consistently report that post-processing steps — such as cutting, support removal, and polishing — consume a great deal of labor and result in high costs. Finding ways to reduce these costs would therefore be highly valuable.

One of these steps — cutting — is now seeing better solutions emerge.

Metal 3D Printed Parts Attached to the Build Plate

When precision metal parts produced by 3D printing are firmly bonded to the build plate, how can they be separated efficiently, without damage, and in a cost-effective way? This seemingly simple “last mile” challenge has actually become one of the major bottlenecks limiting efficiency across the entire additive manufacturing value chain.

The traditional solution — electrical discharge machining (EDM) wire cutting — has been in use for decades, but its limitations are becoming increasingly apparent in the era of high-throughput 3D printing.

A medium-sized, complex part often requires several hours to be cut free, while large, integrated components can take over ten hours of continuous machining. This leads to high equipment occupancy, production bottlenecks, significant power consumption, costly consumables, and additional post-processing work.

When multiple metal 3D printers run around the clock, this cutting stage often becomes the “choke point” on the production line, offsetting much of the efficiency gained during the 3D printing process itself. Even worse, the heat-affected zone generated during EDM cutting can alter the microstructure of the part surface, potentially degrading mechanical properties — an unacceptable risk for high-value, precision components.

Tungsten Wire Loop Cutting – Over 30× Efficiency Boost

Tungsten wire loop cutting technology offers a game-changing solution. Its most striking feature is the dramatic improvement in cutting speed — achieving over 30 times the efficiency of traditional EDM cutting under the same conditions. For example, a job that would traditionally take 26 hours can now be completed in just 45 minutes.

| Equipment | CT | Working Hours (h/day) | Efficiency (%) | Capacity |

| Light Ring Cutting | 0.75 | 22 | 95 | 27.9 times/day |

| EDM Cutting | 26 | 22 | 95 | 0.8 |

Through detailed testing across different materials and sizes, we have obtained some exciting results:

For a 400 × 300 mm titanium alloy build plate, the cutting time is only 40–60 minutes.

For a build plate of the same size made from high-temperature alloys, the cutting time is 60–90 minutes.

In broader tests, titanium alloy plates were cut within 45–150 minutes, while high-temperature alloy plates of the same size required only 45–180 minutes.

| Substrate Size | Printing Material | Cutting Time (minutes) |

| 400×300mm | Titanium Alloy | 40 – 60 |

| 400×300mm | Superalloy | 60 – 90 |

| 850×850mm | Titanium Alloy | 45 – 150 |

| 850×850mm | Superalloy | 45 – 180 |

These data not only reflect a quantitative improvement but also represent a qualitative leap in manufacturing efficiency.

Multi-Return Benefits of the Ring-Cutting Equipment

Even more exciting is that the advantages of this technology go far beyond efficiency improvement. Additional benefits include:

Pure water-cooling system – Completely eliminates the heavy-metal pollution (such as copper and zinc) found in traditional EDM processing, fully meeting today’s stringent environmental requirements.

No heat-affected zone – The physical cutting process ensures that no heat-affected zones are generated, perfectly preserving the microstructure and mechanical properties of the printed parts.

Ultra-low energy consumption – Power usage is only one-fifth that of conventional methods, delivering significant energy-saving and emission-reduction benefits in line with carbon-neutrality goals.

To meet the needs of enterprises of different scales, Da Vinci has developed a complete product matrix:

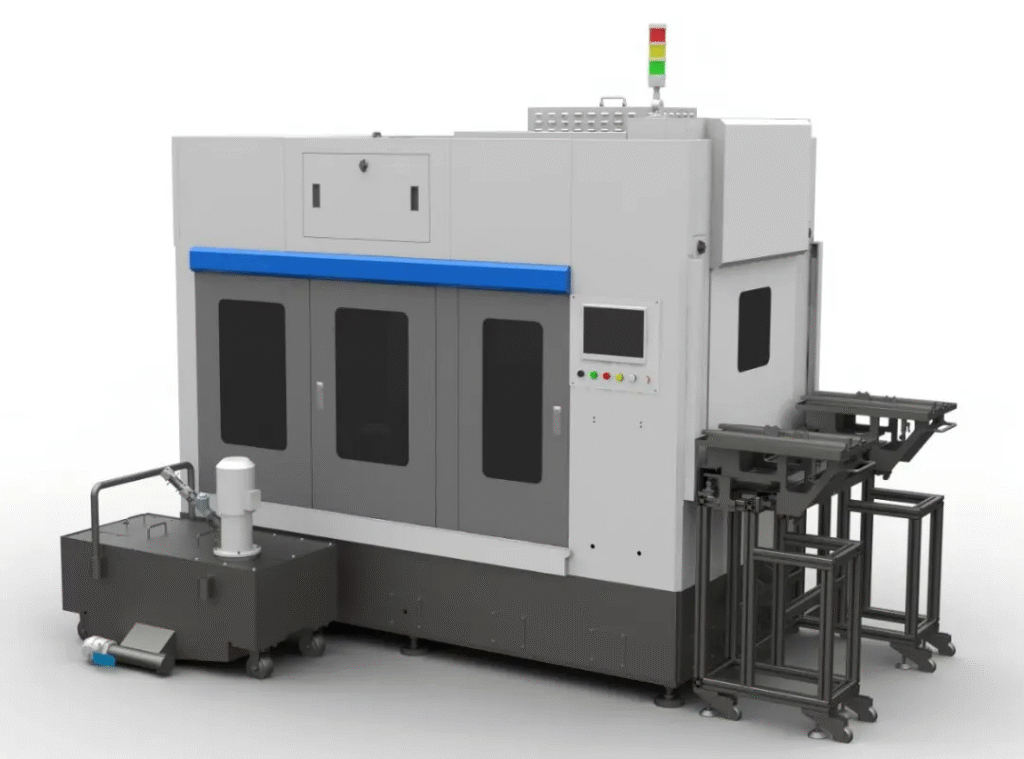

QG4030 model – Specially designed for small and medium-sized printed parts. It is equipped with an intelligent detection system capable of automatically identifying the substrate position and executing precise cutting.

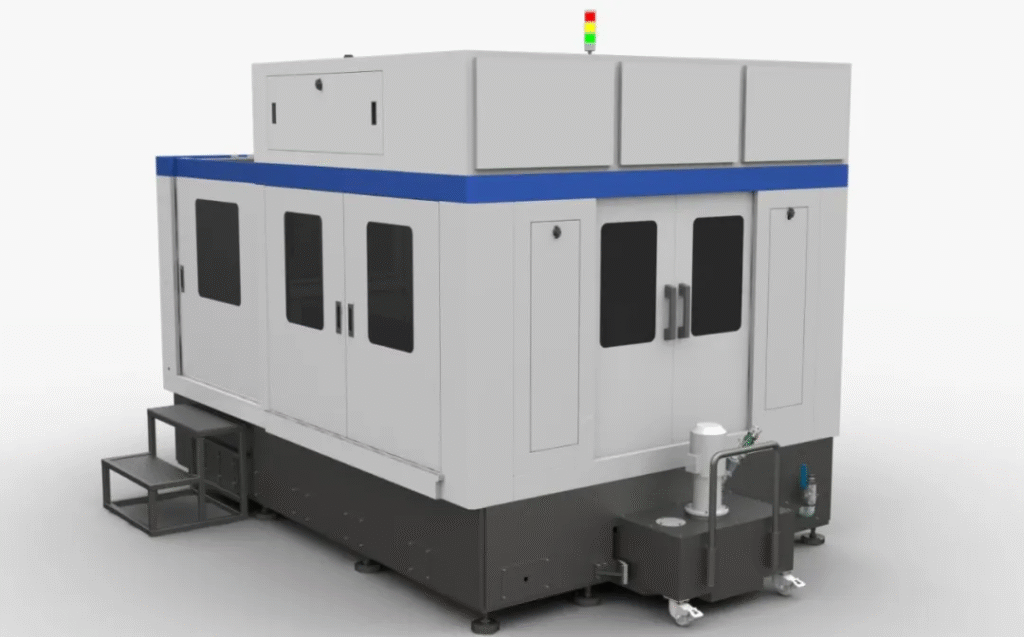

The QG8080 heavy-duty equipment can easily handle large 850mm substrates, and its modular design facilitates maintenance and upgrades.

All equipment is equipped with a remote monitoring system, enabling predictive maintenance and minimizing downtime.