Researchers at Cornell University have published a paper titled “Degradable Thermosets via Orthogonal Polymerizations of a Single Monomer,” focusing on developing a novel polymerization strategy that enables the sustainable redesign of durable plastics. Their work represents a major step toward achieving recyclability and environmental sustainability in traditionally non-degradable thermoset materials.

Items such as car tires and bowling balls are made from thermoset plastics, materials known for their exceptional durability. Their cross-linked polymer chemical structures ensure long lifespans but also make these petroleum-based materials — which account for 15–20% of total polymer production — nearly impossible to recycle.

At present, the global recycling rate for thermoset materials is effectively zero. They are typically either incinerated or discarded in landfills, posing significant environmental and sustainability challenges.

Researchers at Cornell University are addressing this environmental challenge by developing a bio-based alternative that offers the durability and flexibility of cross-linked thermoset plastics, yet can be easily recycled and degraded.

This breakthrough demonstrates a promising path toward sustainable materials innovation, combining high performance with environmental responsibility.

According to corresponding author Brett Fors, this is “an extraordinary chemical reaction” that enables two distinct polymerization processes to occur from a single monomer base.

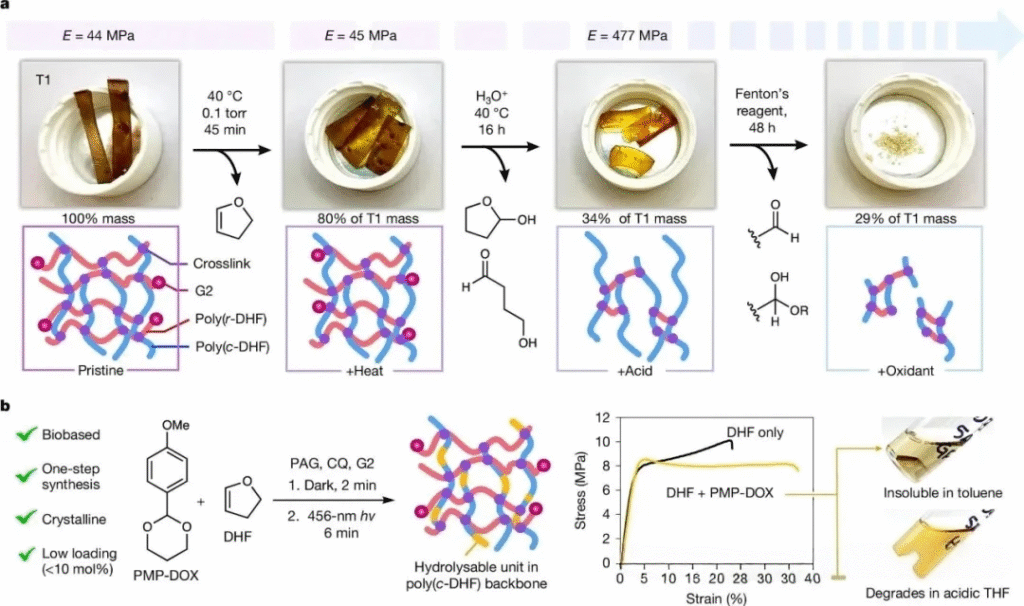

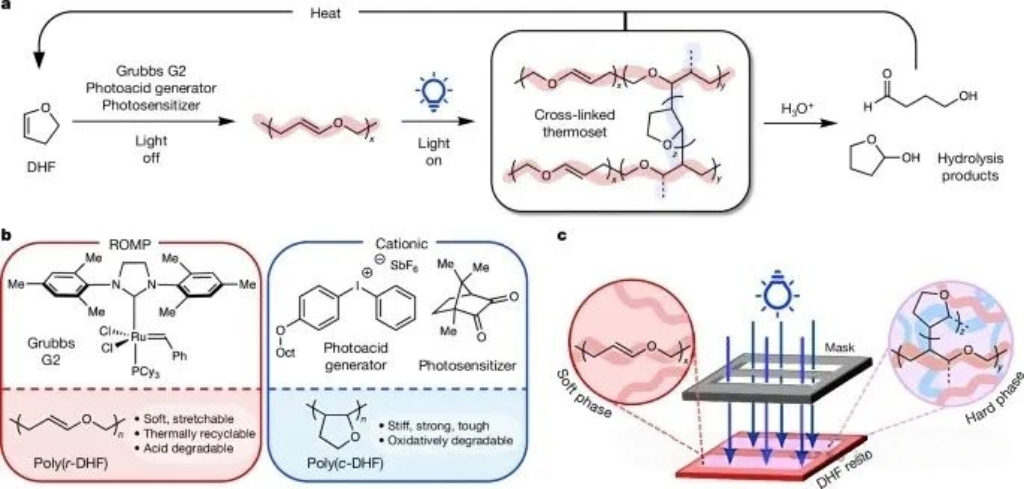

The research team selected dihydrofuran (DHF) — a bio-derived chemical monomer with the potential to eventually replace petroleum-based feedstocks. DHF, a cyclic monomer containing a double bond, serves as the building block for two sequential polymerizations, the second of which generates a cross-linked polymer network.

The first polymerization involves opening the cyclic monomer rings and stitching many of them together into a long, flexible chain. The resulting material is soft and pliable, and can be fully chemically recycled by heating or degraded using acid treatment.

Synthesis of Degradable Thermosets from DHF

However, not all of the DHF is consumed during the first polymerization. The remaining DHF plays a crucial role in toughening the material during the subsequent polymerization step.

In the second stage, the DHF monomers link to each other and to the first polymer while retaining their rigid cyclic structure, resulting in a strong and durable cross-linked material. The final polymer network can be recycled through heating and naturally degrades in the environment.

The first polymer acts as a flexible precursor that preserves the double bonds necessary for forming the second polymer, a reaction that is initiated and controlled by light.

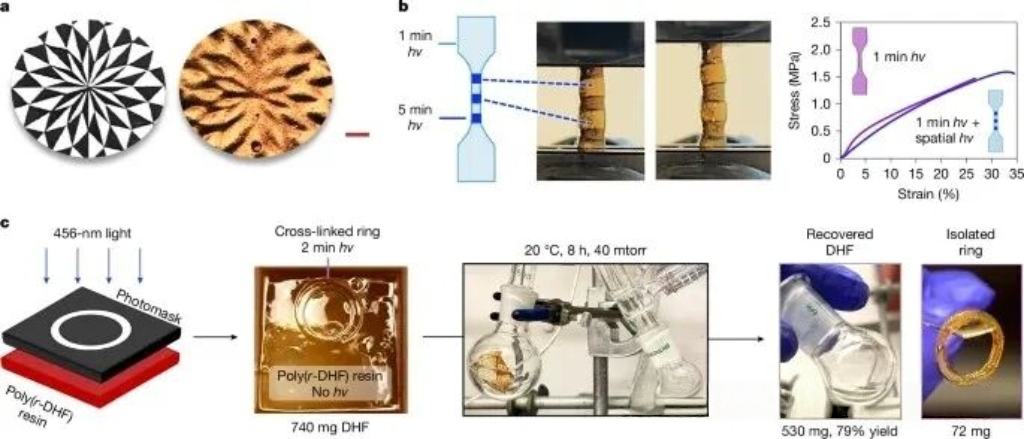

Spatiotemporal Control of DHF-Based Thermoset Materials

The researchers noted that the process is remarkably simple — by adjusting the reaction time, the amount of catalyst, and the intensity of light used in each step, a wide range of material properties can be achieved through a single, straightforward procedure. The more light the material receives, the greater the degree of cross-linking, resulting in increased hardness. Conversely, areas exposed to less light remain more flexible, while unexposed regions can be fully chemically recycled.

The fabrication method employed in this study is photopolymerization-based 3D printing. The combination of photopolymerization and spatiotemporal control introduces new possibilities for the advancement of 3D printing technologies. Furthermore, once cured, the materials can undergo selective and sequential degradation through various methods — including acid hydrolysis, thermal depolymerization, and oxidative degradation — with the degradation products capable of repolymerizing into new materials, thus achieving a closed-loop recycling process.

By integrating orthogonal polymerization mechanisms with photopolymerization technology, the researchers have paved the way for the development of next-generation 3D printing materials that offer complex geometries, precise control, and full degradability. Such materials hold vast potential for applications in biomedicine, aerospace, and automotive manufacturing.

In summary, this research not only provides a novel approach for synthesizing thermoset materials but also offers fresh insights and inspiration for the evolution of photopolymerization-based 3D printing technologies.