The Fraunhofer Institute for Foundry, Composite and Processing Technology (Fraunhofer IGCV), a leading research organization in LPBF multi-material metal 3D printing, has successfully spun off a new company named Fidentis to commercialize its innovations.

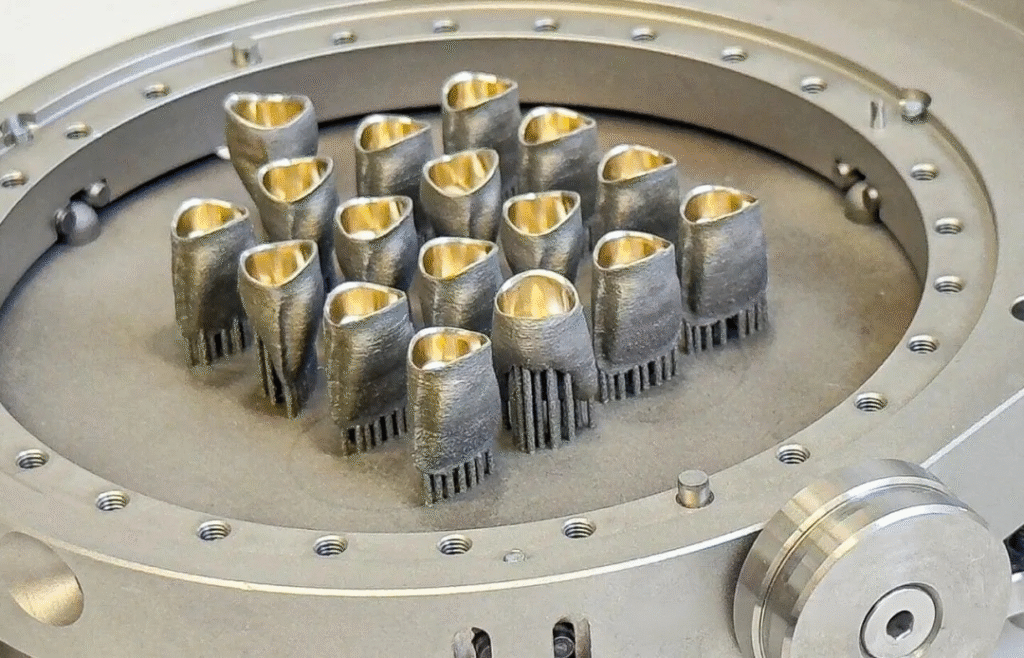

Recently, Fidentis announced the launch of its first LPBF multi-material metal 3D-printed product — a removable dental prosthesis integrally manufactured from cobalt-chromium alloy and gold. The product has officially entered practical use, marking a historic milestone in the field of multi-material metal additive manufacturing.

Fidentis’ Multi-Material Metal 3D Printing Process

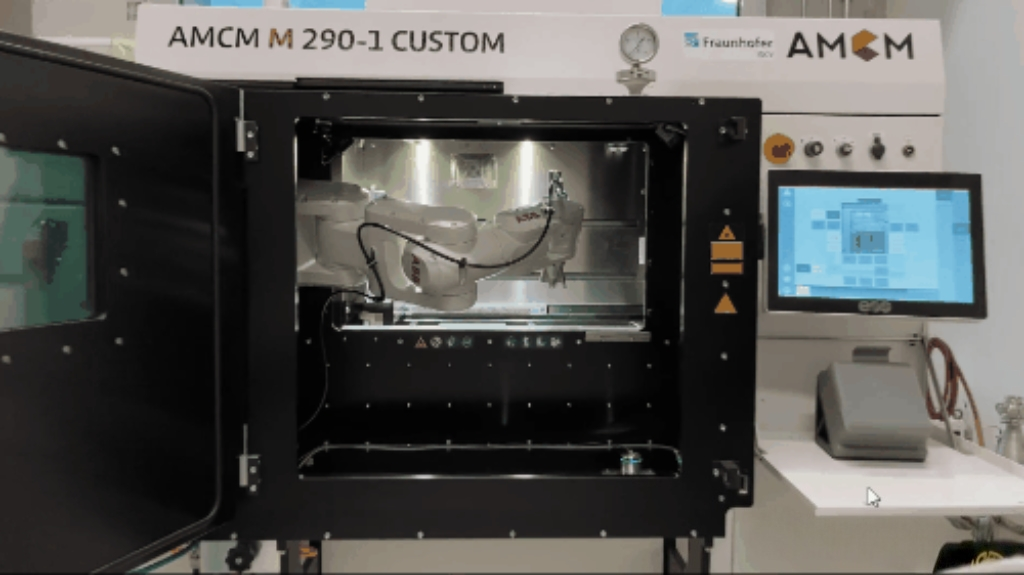

Unlike conventional powder-based additive manufacturing, Fidentis employs a multi-material metal 3D printing approach that integrates a dedicated powder nozzle, powder extraction system, and part-handling manipulator onto an ABB industrial robotic arm mounted on the AMCM 290 platform.

During printing, the second material is applied only where needed, and upon completion, any small areas of mixed material are selectively removed. This fully integrated process control concept was jointly developed by Fraunhofer IGCV and AMCM, enabling precise multi-material deposition and post-processing in a single automated workflow.

Telescopic Crown Dentures in Dental Restoration

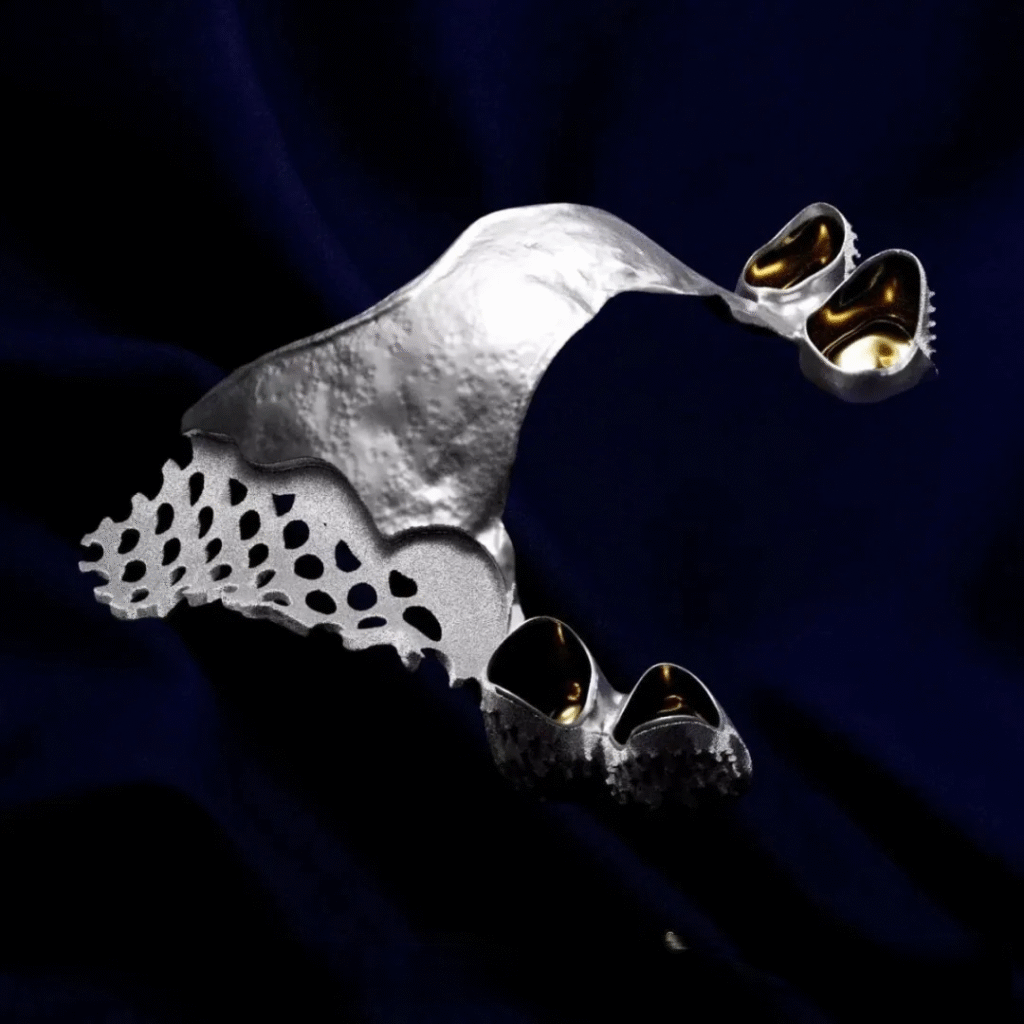

Telescopic crown dentures are one of the techniques used in dental restoration. These prostheses consist of two closely fitting crowns: an inner crown, which is a full metal crown securely cemented onto a prepared natural tooth root or dental implant, and an outer crown, which fits over the inner crown. The inner surface of the outer crown precisely matches the conical outer surface of the inner crown.

The two crowns are tightly nested through precise friction, allowing for a secure fit while still being removable for maintenance. It is important to note that the choice of any dental restoration must be carefully evaluated by a professional dentist.

Furthermore, material selection plays a critical role in ensuring that the inner and outer crowns fit snugly during use yet can be easily removed without excessive force.

Structural Illustration of Telescopic Crown Denture Restoration

According to dental literature, if both the inner and outer crowns are made entirely from non-precious metals, long-term use may result in the crowns becoming “locked”, making removal difficult.

A classic and high-end approach is to use pure gold for the inner surface of the outer crown. Pure gold is extremely soft and ductile, allowing it to conform closely to the inner crown while maintaining smooth removability.

High-End Dental Crowns and Multi-Material Metal 3D Printing

Solid pure gold crowns are prohibitively expensive, while an alternative is a hybrid design combining a precious-metal friction surface with a non-precious metal support structure. According to Fidentis, this solution significantly reduces costs while maintaining performance.

In Germany, however, only a few thousand highly skilled technicians truly master the production of high-end dental restorations (not ordinary crowns). Training is lengthy, exams are demanding, and few young professionals are willing to enter the field.

In this context, multi-material metal 3D printing emerges as a promising and effective solution for countries like Germany that are committed to precision high-end manufacturing, offering both efficiency and consistent quality.

Fraunhofer IGCV’s Robotic Multi-Material Metal 3D Printing Targets Dental Applications

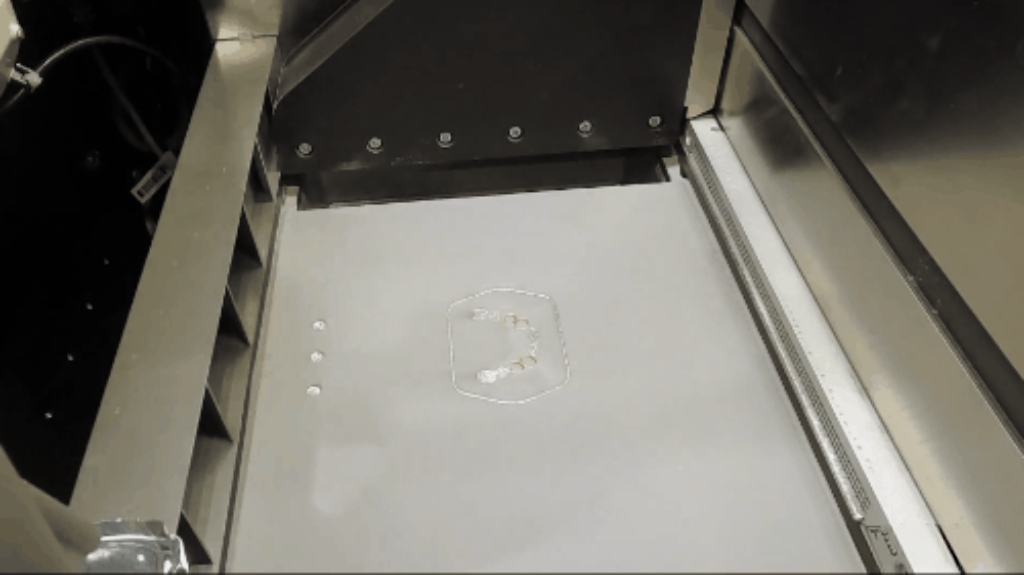

From the outset, Fraunhofer IGCV’s robotic multi-material metal 3D printing was likely aimed at high-precision dental applications. During the development of their multi-material 3D printing process, Fraunhofer IGCV explored various powder deposition methods. A major challenge in multi-material 3D printing is powder mixing, which can lead to significant material waste.

Previous studies in the field have reported several multi-material powder deposition approaches, with mechanical-arm-assisted powder deposition in SLM systems being a typical research method.

Using this approach, Fraunhofer IGCV successfully fabricated dental crowns combining 18k gold and CoCrMo, demonstrating the feasibility and precision of their multi-material 3D printing technology for dental restorations.

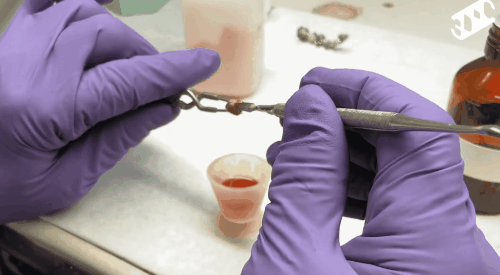

Post-Processing and Advantages of Multi-Material Dental Crowns

After SLM fabrication, the parts are milled using a zero-point clamping system, ensuring the ideal fit of the double crowns. This method has been shown to produce sliding characteristics that remain effective for extended periods in patients’ mouths.

According to Fidentis, the multi-material approach allows dental crowns to be produced at 20 times the speed, reduces production costs by 60%, and minimizes the use of precious metals.

It should be noted that this technology is currently only applied in select institutions and has not been observed domestically. This article is intended solely for technical exchange and application analysis and does not represent any commercial promotion. While this achievement represents a milestone in multi-material metal additive manufacturing, its long-term development remains to be seen.